5052 Aluminum Alloy Powder is a high-performance material known for its excellent mechanical properties, including good formability, high fatigue strength, and superior corrosion resistance. This alloy powder is widely used in various industries, including aerospace, automotive, and marine, where it serves in critical components exposed to demanding environments. Its unique properties make it ideal for applications requiring durability, reliability, and high performance.

Product Overview

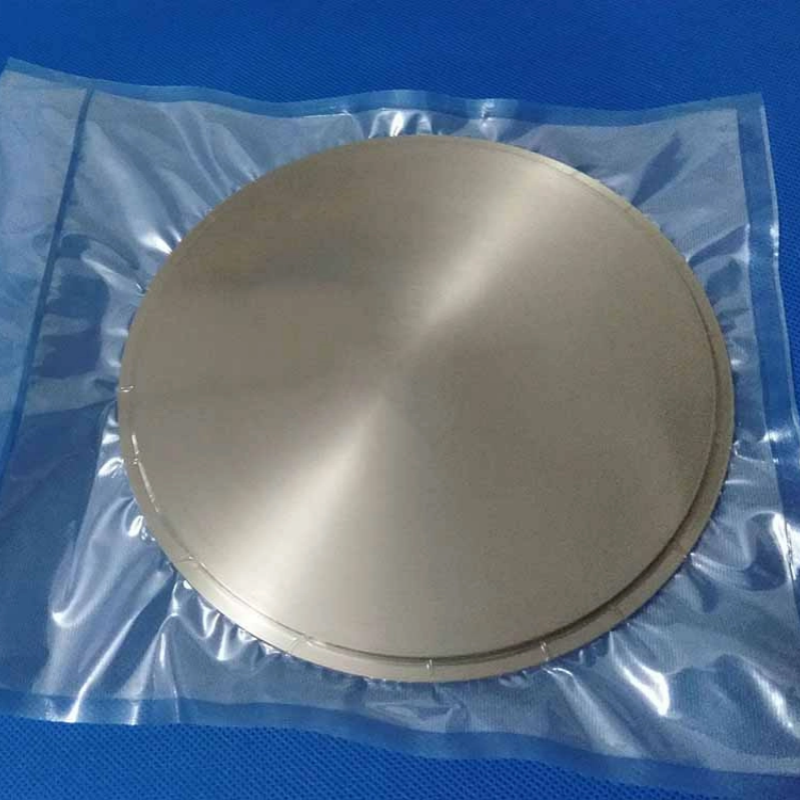

5052 Aluminum Alloy Powder is produced using nitrogen-protected atomization technology, offering excellent particle size distribution and high purity. The powder is derived from 5052 aluminum alloy ingots, with strict control over the production process to ensure consistency and quality. Custom particle sizes are available upon customer request, and we also provide 100g free sample testing to help customers with product verification and application trials.

Product Features

- High Purity (99.9%): Ensures superior physical and chemical properties

- Excellent Particle Size Distribution: Advanced atomization technology ensures uniformity and ease of handling

- Customizable Particle Size: Available in various sizes to meet specific application requirements

- Atomized Gray Appearance: Provides a stable gray powder form suitable for a variety of industrial uses

Applications

- Powder Metallurgy: Used to manufacture high-performance metal components, enhancing material properties through powder metallurgy processes

- MIM and 3D Printing: Serves as raw material for Metal Injection Molding (MIM) and 3D printing, ideal for producing precision parts

- Chemical Industry Additives: Can be used as metal additives in the chemical industry to improve chemical reactions and product performance

- Powder Coating Industry: As a raw material for coatings, providing excellent coating quality and surface finish

| Material | Si | Fe | Mg | Cu | Zn | Mn | Al |

| 5052 Aluminum Alloy Powder | 0.22 | 0.385 | 2.5 | 0.07 | 0.041 | 0.08 | Balance |

new material

new material