Nickel-Cobalt (NiCo) alloy targets are high-performance materials used in various industrial applications, including thin film deposition, aerospace components, and advanced coatings. They are known for their excellent thermal stability, high mechanical strength, and unique properties.

Product Overview:

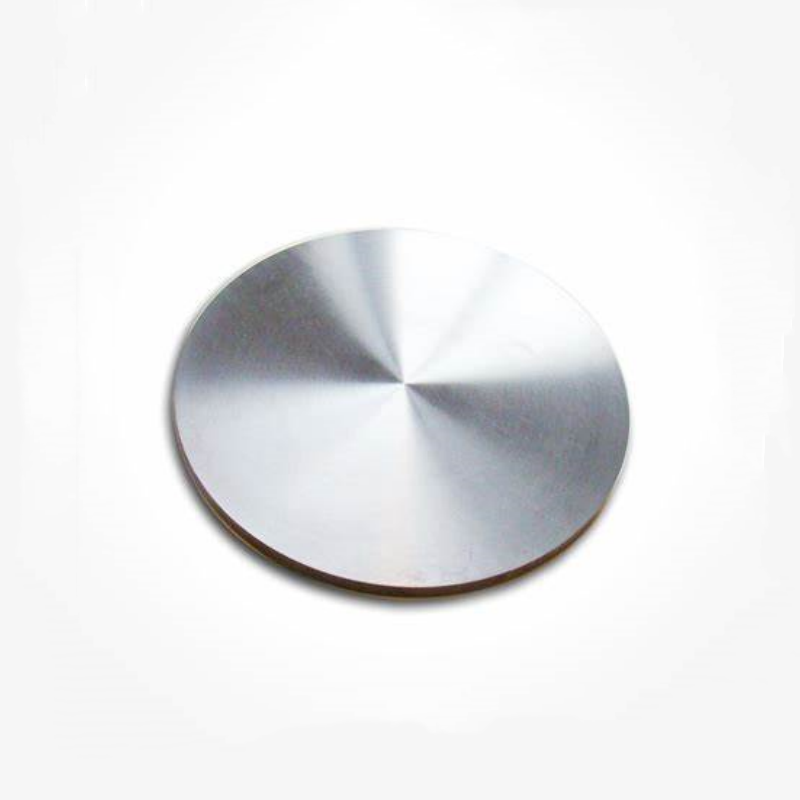

High Purity Nickel-Cobalt Alloy Target Material is composed of nickel and cobalt, showcasing a metallic silver luster and possessing excellent physical and chemical properties. Nickel is a hard, ductile transition metal known for its slow oxidation rate and strong corrosion resistance, while cobalt is a shiny gray ferromagnetic metal primarily used in the production of magnets and high-strength, high-temperature alloys.

Features:

- Outstanding Corrosion Resistance:The slow oxidation rate of nickel allows the alloy to maintain stability in various environments.

- Good Magnetism:As one of the four ferromagnetic elements, nickel enhances the overall magnetic properties of the alloy.

- High Ductility and Toughness:Suitable for various processing methods, improving the versatility of the target material.

- Customization Options:Supports various specifications tailored to customer needs.

Applications:

- Hard Coatings:Nickel-cobalt alloys can be deposited as thin films using Physical Vapor Deposition (PVD) technology, enhancing the wear and corrosion resistance of tools and parts.

- Decorative Coatings:Ideal for surface treatment of products such as jewelry, watches, and smartphones, providing both aesthetic appeal and protection.

- Corrosion-Resistant Coatings:Effective in protecting equipment from corrosion in fields like chemicals, petroleum, and marine engineering, enhancing durability and safety.

new material

new material