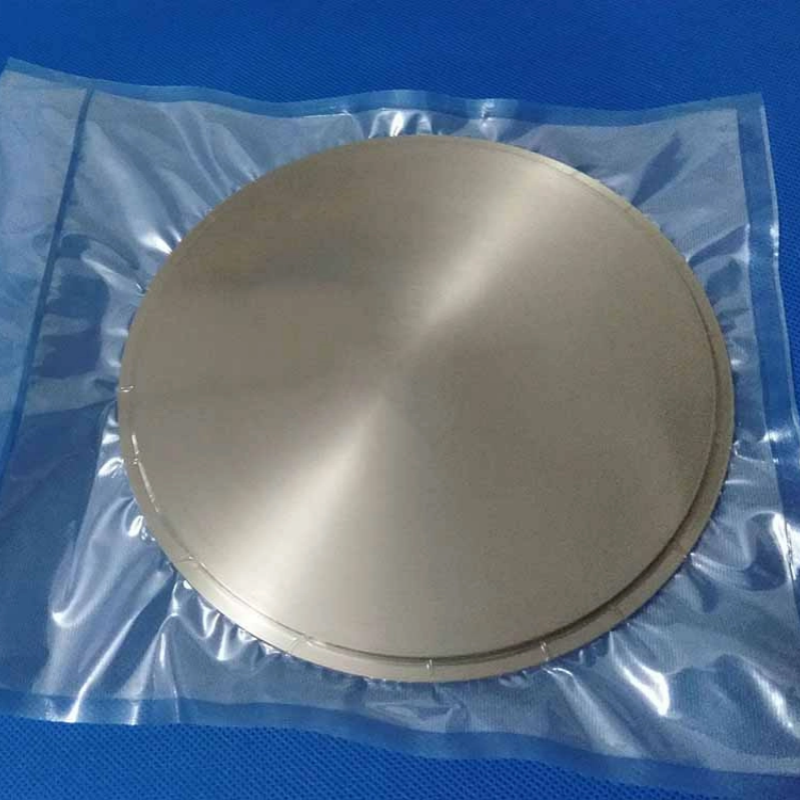

Aluminum-Copper alloy targets are high-performance materials used in various industrial applications, including thin film deposition, aerospace components, and advanced coatings. They are known for their excellent thermal stability, high conductivity, and unique properties.

Product Overview

Aluminum-copper alloy targets are produced using vacuum melting technology and are widely used in integrated circuit manufacturing as interconnect materials. Compared to traditional aluminum interconnects, aluminum-copper alloy targets have a more uniform microstructure, helping to address issues related to electromigration and diffusion. High-purity (5N) and low-oxygen content aluminum-copper targets provide stable corrosion rates and high-quality thin film coatings in PVD (Physical Vapor Deposition) processes, ensuring the high performance and long lifespan of electronic components.

Product Features

- High-purity (5N) aluminum-copper alloy, providing uniform grain size

- Low oxygen content, ensuring film quality and consistency

- Excellent electromigration performance and good diffusion characteristics

- Stable corrosion rate, ensuring consistency during production

- Produces high-purity, uniform thin film coatings in PVD processes

Applications

- Integrated Circuit Manufacturing:Used as interconnect materials to improve chip electrical performance and reliability

- Semiconductor Industry:Used as targets in semiconductor manufacturing for thin film deposition and surface coating

- Electronic Devices:Used in the production of high-precision electronic components, especially in high-frequency and high-performance applications

- Optoelectronics Industry:Used in the production of high-quality optoelectronic devices, ensuring material conductivity and stability

new material

new material