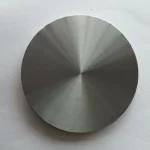

Aluminum-Chromium alloy targets are high-performance materials used in various industrial applications, including thin film deposition, aerospace components, and advanced coatings. They are known for their excellent thermal stability, high oxidation resistance, and unique properties.

Product Overview

Aluminum-chromium alloy targets are produced using advanced hot isostatic pressing (HIP) technology, offering high purity, high density, and fine, uniform grain structure for long-lasting performance. This alloy target performs excellently in a wide range of applications, particularly in industries requiring high-quality thin film coatings. Its stable sputtering rate and uniform coating layers make it an ideal choice for precision surface treatments.

Product Features

- High purity (3N), ensuring quality and consistency of the target material

- Fine, uniform grain structure, helping to provide stable sputtering rates

- High density, close to 99% actual density, extending service life

- Produced using hot isostatic pressing to ensure uniform structural integrity

- Customizable in various shapes and sizes upon customer request, such as rectangular or arc-shaped targets

Applications

- Semiconductor Manufacturing:Used for thin film deposition and electronic component production, providing high-quality thin film coatings

- Optical Coatings:Applied in optical devices, ensuring uniform coating layers

- Surface Treatment:Widely used for surface coatings requiring high wear resistance and high electrical conductivity

- Electronics Industry:Used in the manufacturing of high-precision electronic components, ensuring material performance stability

- Metal Coatings:Applied in automotive, aerospace, and other fields for metal coatings, enhancing durability and corrosion resistance

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | ppm | Zn | ppm | Pb | <10 | ppm | |||||

| B | ppm | Ga | ppm | Bi | <10 | ppm | |||||

| F | ppm | Ge | ppm | Y | ppm | ||||||

| Na | ppm | As | ppm | Th | ppm | ||||||

| Mg | ppm | Se | ppm | Er | ppm | ||||||

| Al | Matrix | wt% | Zr | <10 | ppm | Ru | ppm | ||||

| Si | 405 | ppm | Nb | <10 | ppm | Rb | ppm | ||||

| P | ppm | Mo | <10 | ppm | Sr | ppm | |||||

| Cl | ppm | Pd | ppm | Sc | ppm | ||||||

| K | ppm | Ag | ppm | Be | ppm | ||||||

| Ca | ppm | Sn | ppm | Rh | ppm | ||||||

| Ti | ppm | Sb | ppm | Cd | <10 | ppm | |||||

| V | ppm | Ba | ppm | ||||||||

| Cr | 45.32 | wt% | Hf | ppm | |||||||

| Mn | ppm | Ta | <10 | ppm | C | <10 | ppm | ||||

| Fe | 460 | ppm | W | <10 | ppm | S | <10 | ppm | |||

| Co | ppm | Pt | ppm | O | 2260 | ppm | |||||

| Ni | 20 | ppm | Au | ppm | N | 80 | ppm | ||||

| Cu | ppm | Hg | ppm | H | ppm |

new material

new material