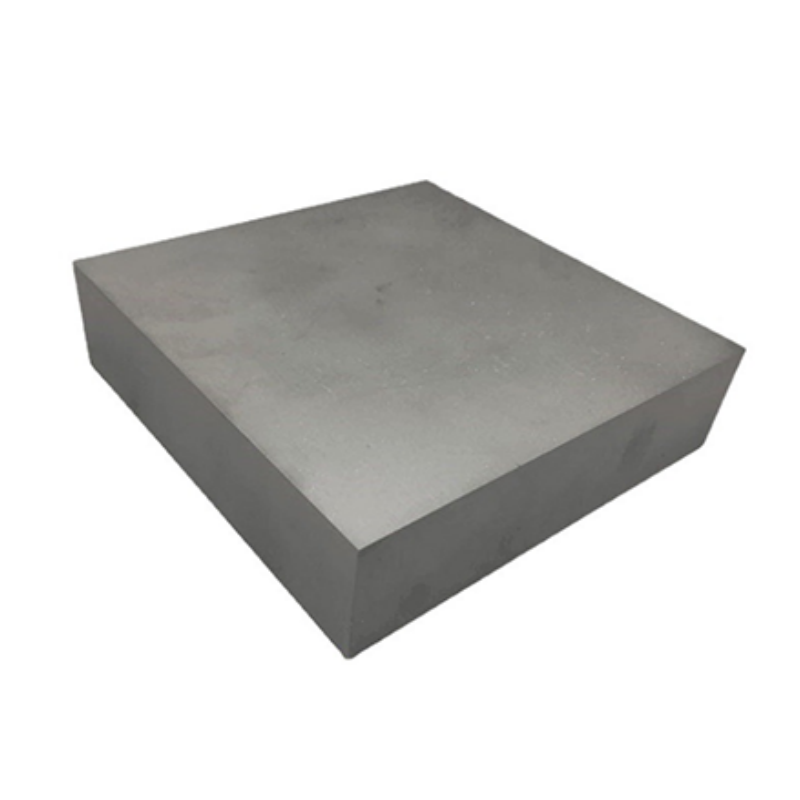

Tungsten-Titanium-Tantalum-Niobium (WTiTaNb) Hard Alloy is a high-performance material known for its exceptional hardness, wear resistance, and high-temperature strength. This alloy is widely used in various industries, including aerospace, machining, and manufacturing, where it serves in critical components exposed to demanding environments. Its unique properties make it ideal for applications requiring durability, reliability, and high performance.

Product Overview

Tungsten-Titanium-Tantalum-Niobium (WTiTaNb) hard alloy is a composite material produced through powder metallurgy, combining refractory metal compounds with a binding metal. This alloy integrates the excellent properties of tungsten, titanium, tantalum, and niobium, offering exceptionally high hardness, wear resistance, and strength. It also boasts excellent high-temperature resistance, corrosion resistance, and other outstanding features. This alloy is widely used in industrial applications that demand high strength, wear resistance, and the ability to perform under high-temperature conditions.

Key Features

- Outstanding Hardness and Wear Resistance: Tungsten-titanium-tantalum-niobium hard alloy possesses extremely high hardness, maintaining its excellent hardness and shape even under high-temperature and harsh environments. It is particularly suitable for high-load and high-wear applications.

- High-Temperature Resistance: The alloy maintains stable performance even at 500°C, and retains high hardness up to 1000°C, making it suitable for high-temperature operational environments.

- High Strength and Toughness: The alloy has good mechanical strength and toughness, capable of withstanding shock and heavy loads.

- Corrosion Resistance: Tungsten-titanium-tantalum-niobium hard alloy offers strong resistance to chemical corrosion, maintaining stability even in harsh chemical environments.

Applications

- Cutting Tool Materials: Used in the manufacture of turning tools, milling cutters, planing tools, drill bits, boring tools, and other cutting tools. It is suitable for machining cast iron, non-ferrous metals, plastics, synthetic fibers, graphite, glass, stone, and common steels.

- Machining Difficult Materials: Ideal for processing heat-resistant steels, stainless steels, high-manganese steels, tool steels, and other hard-to-machine materials.

- High-Temperature and Wear-Resistant Components: Used in the production of molds, cutting tools, wear-resistant liners, and other components that need to work efficiently under extreme conditions for long periods.

new material

new material