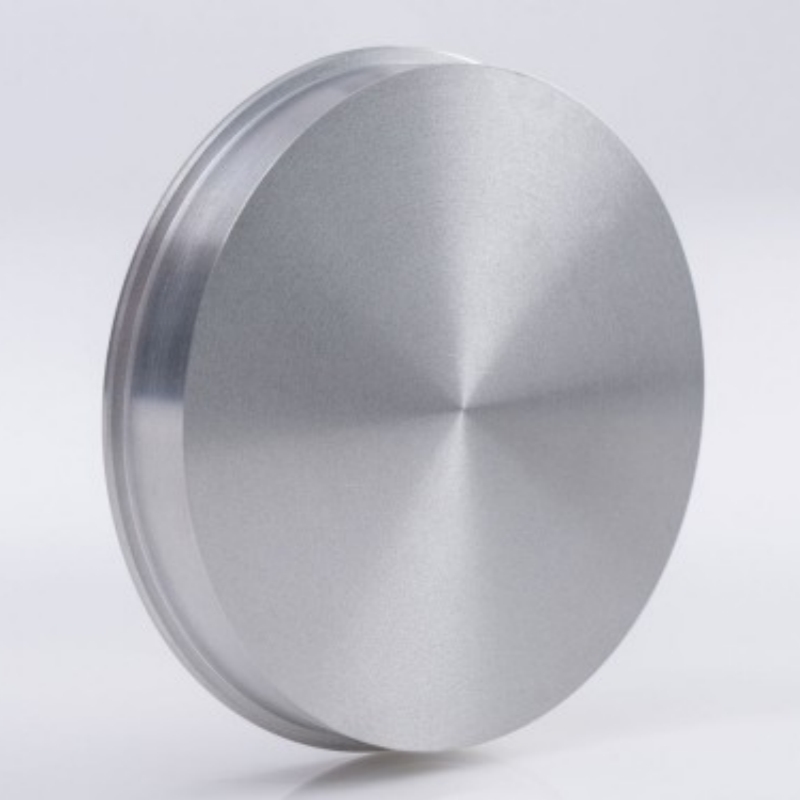

Tungsten-Titanium (W-Ti) alloy targets are high-performance materials extensively used in industrial applications, including thin film deposition, semiconductor manufacturing, and advanced coatings. Known for their exceptional thermal stability, high strength, and unique properties, these targets are ideal for demanding environments and advanced technological processes.

Product Overview

Tungsten-titanium alloy targets are produced using powder metallurgy technology, offering a metallic gray appearance. These targets are widely used in fields such as semiconductors, thin-film solar cells, LEDs, and tool coatings. The target is especially suitable for PVD (Physical Vapor Deposition) processes, providing stable, uniform thin film coatings due to its excellent film-forming properties and high purity. The tungsten-titanium alloy target's purity can reach 3N5, with low gas content and small grain size, ensuring a consistent corrosion rate during sputtering and improving the quality and performance of the thin films.

Product Features

- High purity, ensuring excellent conductivity and stability of the thin films

- Uniform grain size, with an average particle diameter of less than 100μm

- Low gas content, ensuring high-quality film deposition

- Customizable composition based on customer requirements (e.g., WTi 90/10wt%, WTi 85/15wt%, etc.)

- Special annealing treatment, enhancing the target's performance and lifespan

Applications

- Semiconductor Manufacturing:Used for thin-film diffusion barrier layers and adhesion layers, preventing direct contact between metal layers and semiconductor materials, improving the functionality and stability of microchips

- Thin-Film Solar Cells:Used as a barrier layer to prevent iron atoms in the steel substrate from diffusing into the molybdenum back contact and CIGS semiconductor, enhancing solar cell efficiency

- LED Manufacturing:Used for high-performance LED coatings, enhancing device performance and lifespan

- Tool Coatings:Provides high hardness and wear-resistant coatings for tools, improving their lifespan and processing accuracy

new material

new material