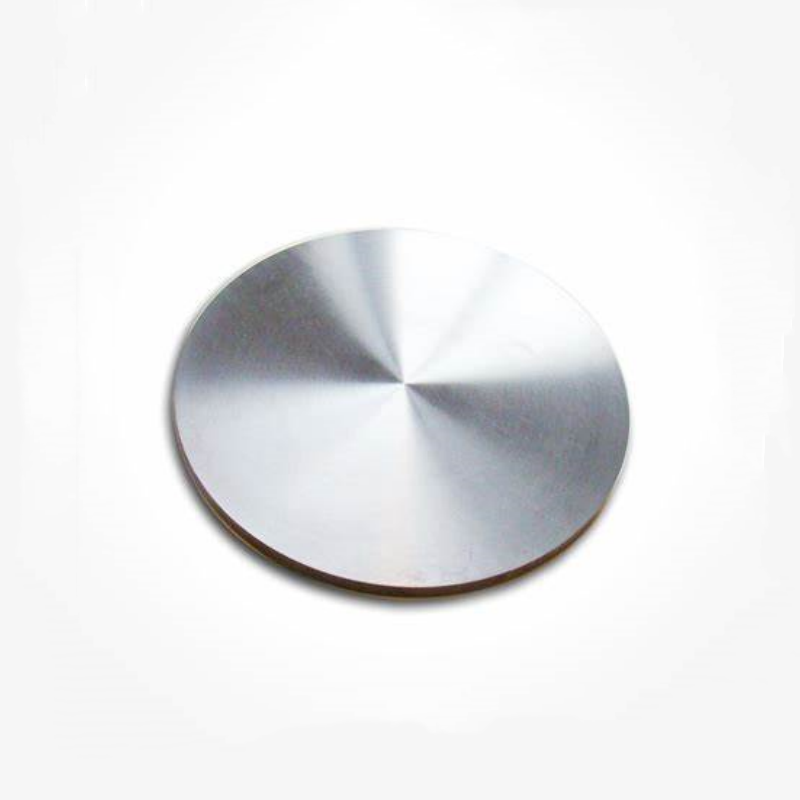

Cobalt-Chromium alloy targets are high-performance materials used in various industrial applications, including thin film deposition, medical device manufacturing, and advanced coatings. They are known for their excellent thermal stability, high corrosion resistance, and unique properties.

Product Overview

The CoCr alloy target is a high-density material made from cobalt and chromium, with a silvery-gray metallic sheen. It has a density of 8.0 - 9.0 g/cm³ and a hardness of Mohs 5-6, with a melting point between 1300°C and 1400°C. Small amounts of molybdenum, tungsten, or nickel can be added to enhance corrosion resistance and hardness, depending on requirements.

Key Features

- High Hardness and Wear Resistance:With high hardness, this alloy is suitable for demanding, high-strength applications.

- Heat and Corrosion Resistance:Performs well in high-temperature environments with strong corrosion resistance.

- Customizable Specifications:Can be manufactured to custom sizes based on drawings, adaptable to various applications.

- High Electrical Conductivity:Suitable for electronic and microelectronic products requiring conductive properties.

Applications

- Semiconductor Manufacturing:Widely used in integrated circuits and microelectronics for creating conductive pathways and connections.

- Solar Cells:Used to deposit conductive layers, enhancing thin-film photovoltaic efficiency and durability of solar cells.

- Magnetic Materials:Ideal for thin films with high magnetic permeability and stability, applicable in hard drives, motors, and transformers.

new material

new material