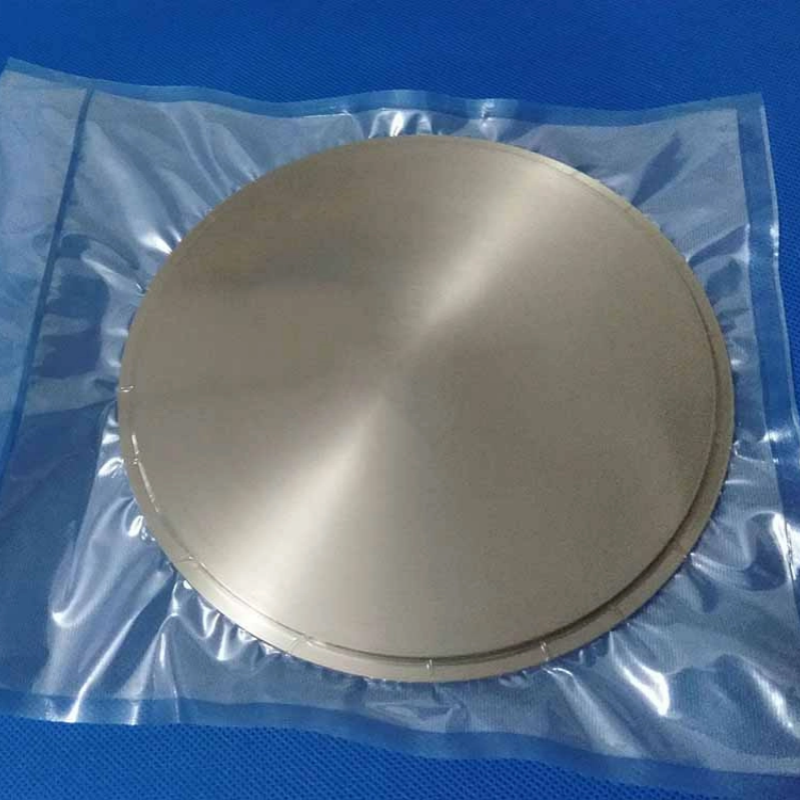

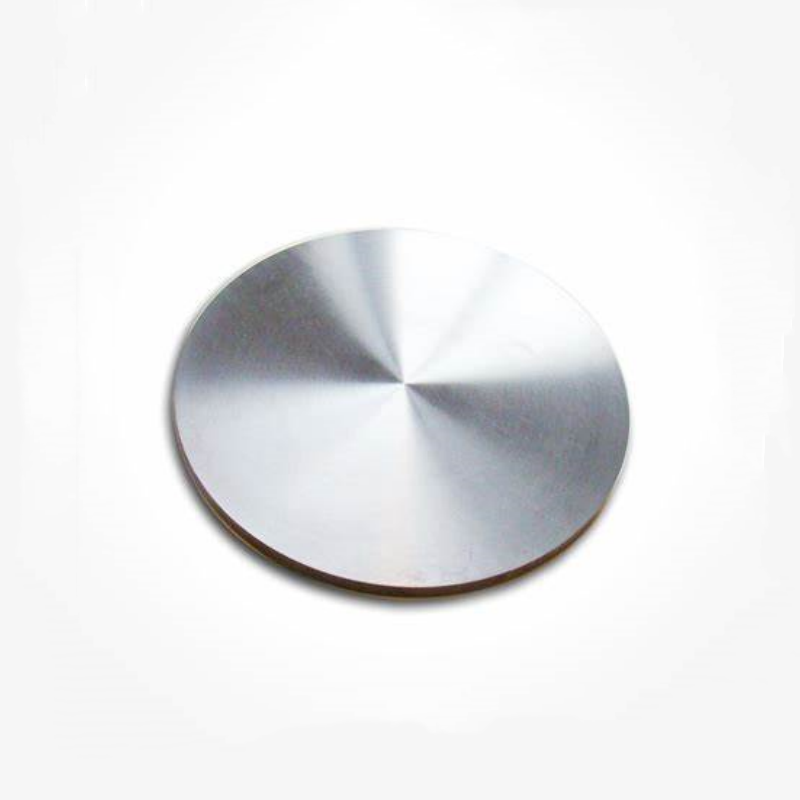

Nickel-niobium intermediate alloy (Nb65%) is an advanced metallurgical material designed for superior strength, thermal stability, and corrosion resistance. The high niobium content enhances grain refinement, oxidation protection, and wear resistance, making it an essential material for aerospace components, industrial applications, and high-performance electronics. This alloy is widely used in specialized coatings, superconducting technologies, and precision manufacturing.

Product Overview

Nickel-niobium intermediate alloy (Nb65%) is used as a niobium additive in the casting of nickel-based superalloys, special alloys, and special steels. By providing high-purity niobium, this alloy enhances the high-temperature strength, oxidation resistance, and corrosion resistance of the alloy. It exhibits excellent performance in high-temperature environments and is a critical material for aerospace, energy, and other industries.

Key Features

- Provides high-purity niobium to effectively improve the high-temperature performance of alloys.

- Enhances oxidation resistance and corrosion resistance in nickel-based superalloys.

- Increases the strength and thermal stability of casting alloys.

- Improves the mechanical properties of special alloys and special steels.

- Suitable for special applications in high-temperature and high-pressure environments.

Applications

- Nickel-Based Superalloys:Used to add niobium to nickel-based alloys to enhance high-temperature performance.

- Special Alloys and Special Steels:Used to manufacture high-strength, high-heat-resistant alloys.

- Aerospace:Used in spacecraft, engine components, and other materials requiring high-temperature stability.

- Energy Sector:Enhances the service life and durability of alloys under high-temperature conditions.

- Casting Industry:Used to produce casting alloys requiring high-temperature strength and oxidation resistance.

new material

new material