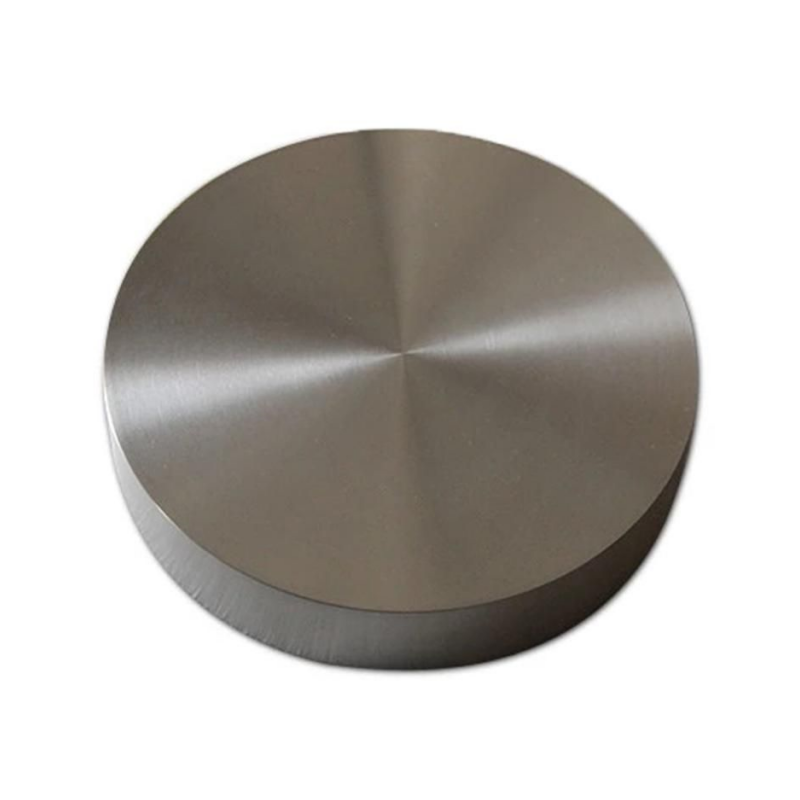

Nickel-Iron-Cobalt Alloy is a high-performance material known for its excellent magnetic properties, high permeability, and thermal stability. This alloy is widely used in various industries, including electronics, aerospace, and medical devices, where it serves in critical components exposed to demanding environments. Its unique properties make it ideal for applications requiring durability, reliability, and high performance.

Product Overview

Nickel-iron-cobalt alloy is a high-performance material composed of nickel, iron, and cobalt, known for its excellent high-temperature and corrosion resistance. The unique composition of the alloy gives it outstanding strength and stability in high-temperature environments, making it ideal for critical components operating under extreme conditions. This alloy is commonly used in manufacturing parts for aerospace engines that endure high temperatures, corrosion, and pressure.

Features

- Excellent high-temperature resistance, suitable for long-term use in environments below 650°C

- Outstanding corrosion resistance, capable of withstanding harsh environments

- High strength with excellent structural stability

- Good machinability, suitable for precision manufacturing

Applications

- Aerospace: Engine ring components

- Space: High-temperature parts and casings

- High-Temperature Equipment: Heat-resistant components for aerospace engines

new material

new material