Cobalt-Chromium-Tungsten alloy targets are high-performance materials used in various industrial applications, including thin film deposition, aerospace components, and advanced coatings. They are known for their excellent thermal stability, high wear resistance, and unique properties.

Product Overview

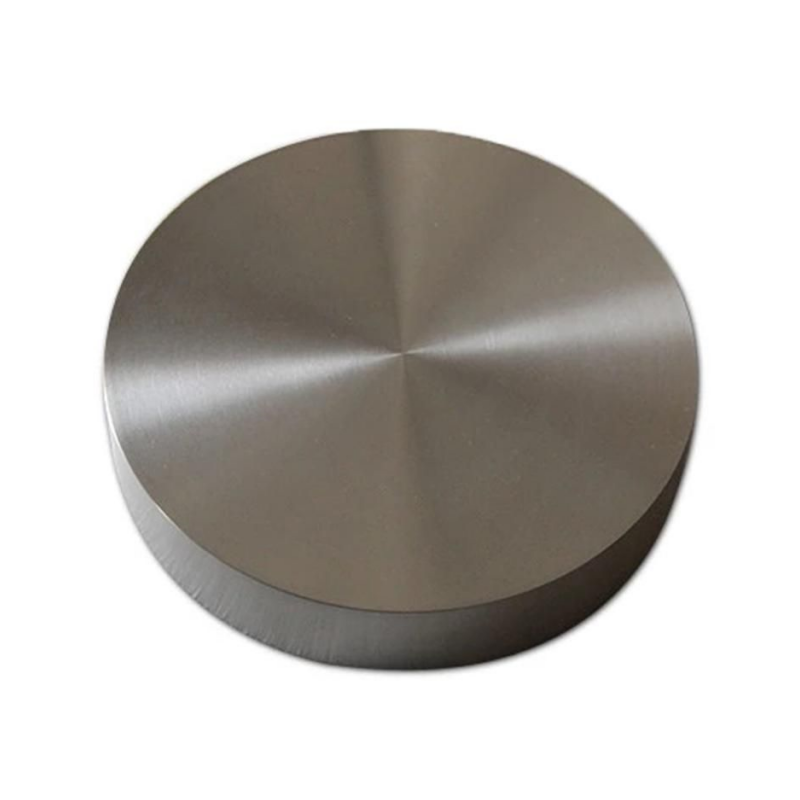

The CoCrW alloy target has a silver-white appearance. Initially produced using non-vacuum melting and casting techniques, it was later refined with vacuum melting and casting methods, significantly improving its purity and performance. The CoCrW target exhibits excellent resistance to thermal fatigue, heat corrosion, and wear at temperatures above 980°C, along with good weldability.

Key Features

- High Temperature Strength:Excellent strength and stability at high temperatures (above 980°C).

- Thermal Resistance:Great resistance to thermal fatigue and corrosion, making it suitable for prolonged high-temperature environments.

- Wear Resistance:Ideal for surface coatings to extend material lifespan.

- Advanced Manufacturing:Produced using vacuum induction melting to ensure high purity and quality.

Applications

- Aerospace:Suitable for jet engine guide vanes and nozzle guide vanes.

- Energy Equipment:Components for industrial and marine gas turbines.

- Automotive:Thin film coatings for diesel engine nozzles.

new material

new material