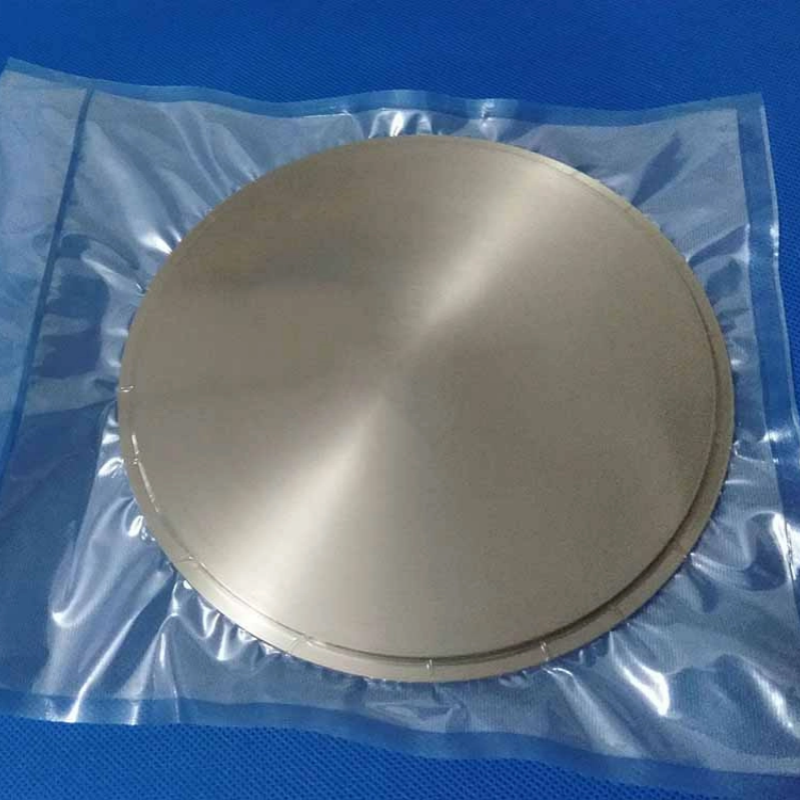

Copper-iron alloy (CuFe10wt%) is a high-performance metallurgical material known for its excellent mechanical strength, corrosion resistance, and thermal conductivity. The addition of iron enhances the alloy’s wear resistance, oxidation protection, and structural integrity, making it ideal for aerospace components, automotive applications, industrial machinery, and precision manufacturing. Copper-iron alloy plays a crucial role in advanced metallurgy, sustainable engineering, and specialized material solutions.

Product Overview

Copper iron alloy is an intermediate alloy composed of copper and iron, widely used in the manufacture of electrical equipment and the production of building materials. This alloy effectively improves the mechanical properties and corrosion resistance of copper, while enhancing the alloy's conductivity and thermal stability. Copper iron alloy is an ideal functional material, enabling precise element addition during metal refining, optimizing alloy composition, and solving issues such as burn-off, segregation, and high melting points.

Key Features

- Enhances the strength and hardness of the alloy.

- Improves copper's wear resistance and corrosion resistance.

- Increases thermal stability and electrical conductivity.

- Easily melts with fast dissolution speed, allowing for quick composition adjustment during refining.

Applications

- Electrical Equipment Manufacturing:Used in the production of electrical conductors, connectors, and other electrical components.

- Building Materials Manufacturing:Used to produce copper alloy materials for construction, improving material corrosion resistance and strength.

- Metal Refining:Used as an additive to optimize the composition of other alloys and improve the uniformity of elements during the refining process.

new material

new material