Aluminum-strontium alloy (ALSr10) is a high-performance metallurgical material designed for grain refinement and structural enhancement in aluminum-based alloys. It is widely used in automotive manufacturing, aerospace engineering, and precision casting applications. Due to its ability to improve mechanical properties and thermal stability, aluminum-strontium alloy plays a crucial role in advanced material development, sustainable engineering, and high-performance industrial solutions.

Product Overview

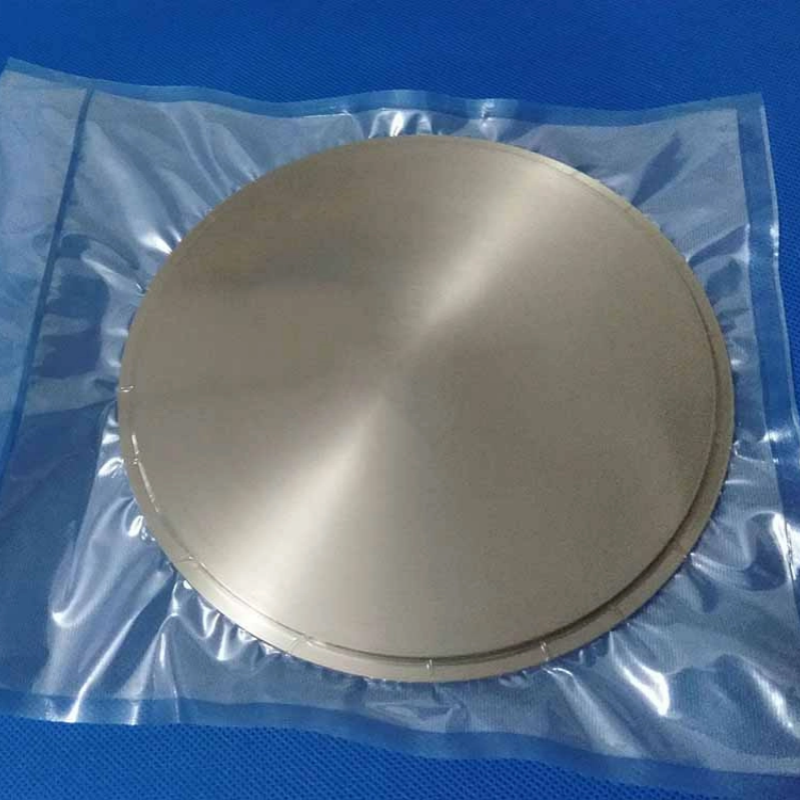

Aluminum strontium alloy (ALSr10) contains 9–11% strontium and is specifically designed as a long-lasting modifier for aluminum-silicon alloys. The addition of strontium significantly improves the grain structure of aluminum-silicon alloys, refining the silicon grains, and enhancing the alloy's strength, toughness, and heat resistance. This alloy is widely used for modifying aluminum-silicon alloys, improving the overall performance of aluminum alloys, especially in applications requiring long-term stable performance.

Key Features

- The strontium content (9–11%) effectively refines the grain structure of aluminum-silicon alloys, improving their strength and toughness.

- Suitable for aluminum-silicon alloys with less than 13% silicon content, used as a long-lasting modifier.

- Enhances the heat resistance, oxidation resistance, and machinability of the alloy.

- Good plasticity and machinability, allowing for customization into different shapes as needed.

- Maintains stability and performance of the alloy during long-term high-temperature use.

Applications

- Aluminum Alloy Production:Used for modifying aluminum-silicon alloys, particularly as a long-lasting modifier during the production of aluminum-silicon alloys.

- Automotive Industry:Applied in aluminum alloy engine and transmission components to improve their strength, toughness, and heat resistance.

- Aerospace:Used to enhance the performance of aluminum alloy structural parts in aircraft, especially in high-temperature environments.

- Metallurgical Industry:Used during the aluminum alloy smelting process to improve the fluidity and casting properties of aluminum-silicon alloys.

- Machinery Manufacturing:Used in the production of aluminum alloy components that require high strength and heat resistance, improving their overall performance.

new material

new material