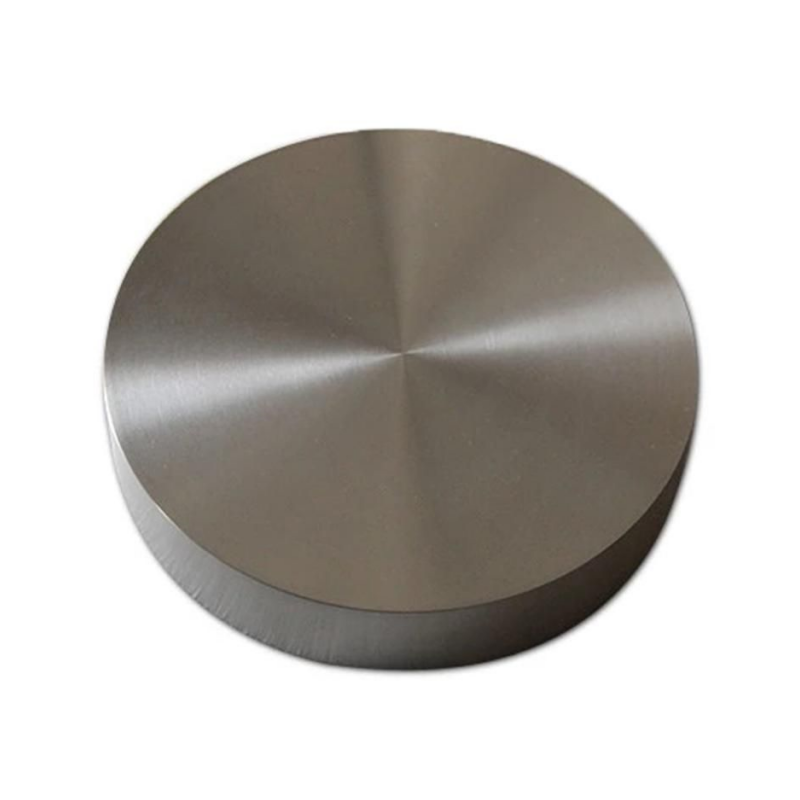

316L Stainless Steel Powder is a low-carbon austenitic stainless steel powder with exceptional corrosion resistance, good mechanical properties, and excellent weldability. It is widely used in aerospace, medical, and industrial sectors for applications such as additive manufacturing, metal injection molding, and precision engineering, offering high durability and reliable performance.

Product Overview

316L Stainless Steel Powder is a powder material with excellent corrosion resistance, high-temperature resistance, and high strength. It is widely used for manufacturing components and products that require high corrosion resistance, particularly in industries such as chemical, petroleum, and marine applications. The low carbon content of this stainless steel powder prevents carbide formation during welding, maintaining superior mechanical properties.

Product Features

- Excellent Corrosion Resistance:High resistance to corrosion in chloride and other corrosive environments.

- High-Temperature Performance:Maintains excellent mechanical properties in high-temperature environments, making it suitable for high-temperature applications.

- Good Machinability:Easy to shape and process, ideal for 3D printing and other advanced manufacturing technologies.

- Low Carbon Content:The low carbon content effectively prevents carbide formation during welding, ensuring high-quality welds.

- High Strength and Toughness:Provides high strength and toughness, suitable for applications with high loads and impact forces.

Applications

- Chemical and Petroleum Industry:Used for manufacturing corrosion-resistant equipment and pipeline systems.

- Marine Engineering:Applied to produce corrosion-resistant parts and equipment in marine environments.

- Medical Equipment:Used for manufacturing medical instruments and surgical tools due to its good biocompatibility.

- Food and Beverage Industry:Ideal for food processing equipment, storage containers, etc., due to its corrosion resistance.

- Aerospace:Used in the production of high-performance aerospace components.

new material

new material