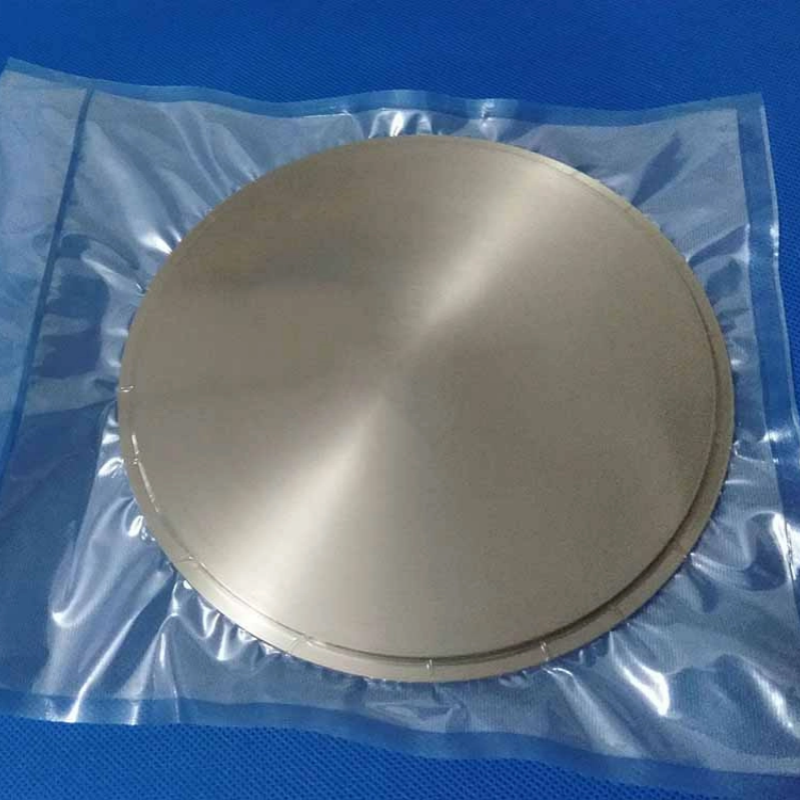

Zirconia (ZrO₂) lump is a high-purity ceramic material renowned for its excellent thermal stability, mechanical strength, and resistance to wear and corrosion. It is widely used in advanced ceramics, cutting tools, dental implants, refractory applications, and structural components. Due to its outstanding properties, zirconia plays a critical role in precision engineering, biomedical applications, and high-performance industrial solutions.

Product Overview

Zirconia (ZrO₂) is a highly refractory and hard inorganic compound, known for its exceptional high melting point, strength, and resistance to corrosion. It is widely used in high-temperature, corrosion-resistant, and high-strength applications. With its metallic luster and excellent thermal stability, zirconia is commonly utilized in the production of ceramics, refractory materials, and the smelting of steel and precious metals. Zirconia lumps offer excellent mechanical properties, especially in high-temperature and corrosive environments.

Features

- High Melting Point and Hardness: Ideal for high-temperature, high-pressure applications

- Metallic Luster: Provides excellent chemical stability

- Outstanding Corrosion and Wear Resistance: Performs well in harsh environments

- Customizable Sizes: Can be tailored to specific requirements

Applications

- Ceramics Industry: Widely used in the production of piezoelectric ceramics, daily-use ceramics, and refractory materials

- Metal Smelting: Essential in the smelting of precious metals, including the production of zirconium bricks, zirconium tubes, and crucibles

- Aerospace: Used in high-temperature insulation materials and ceramic matrix composites

- Optics & Electronics: Applied in the production of optical glass and in the manufacturing of steel and non-ferrous metals

- Functional Ceramics: Ideal for the production of functional ceramics and structural ceramics, or as grinding media

- Other Industrial Applications: Serves as an inert filler and strength enhancer in plastics, rubber, and latex industries, providing high-temperature protection and mechanical strength

- Cosmetics: Used in pigments and various cosmetic formulations

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | Zn | Pb | |||||||||

| B | Ga | Bi | |||||||||

| F | Ge | Y | |||||||||

| Na | As | Th | |||||||||

| Mg | 2 | ppm | Se | Er | |||||||

| Al | 1.2 | ppm | Zr | ppm | Ru | ||||||

| Si | 8 | ppm | Nb | Rh | |||||||

| P | Mo | Os | |||||||||

| Cl | Pd | Cd | |||||||||

| K | Ag | In | |||||||||

| Ca | Sn | ||||||||||

| Ti | Sb | ||||||||||

| V | 7 | ppm | Ba | ||||||||

| Cr | 3 | ppm | Hf | ||||||||

| Mn | Ta | C | |||||||||

| Fe | W | S | |||||||||

| Co | 28 | ppm | Pt | O | ppm | ||||||

| Ni | 4 | ppm | Au | N | |||||||

| Cu | 5 | ppm | Hg | H |

new material

new material