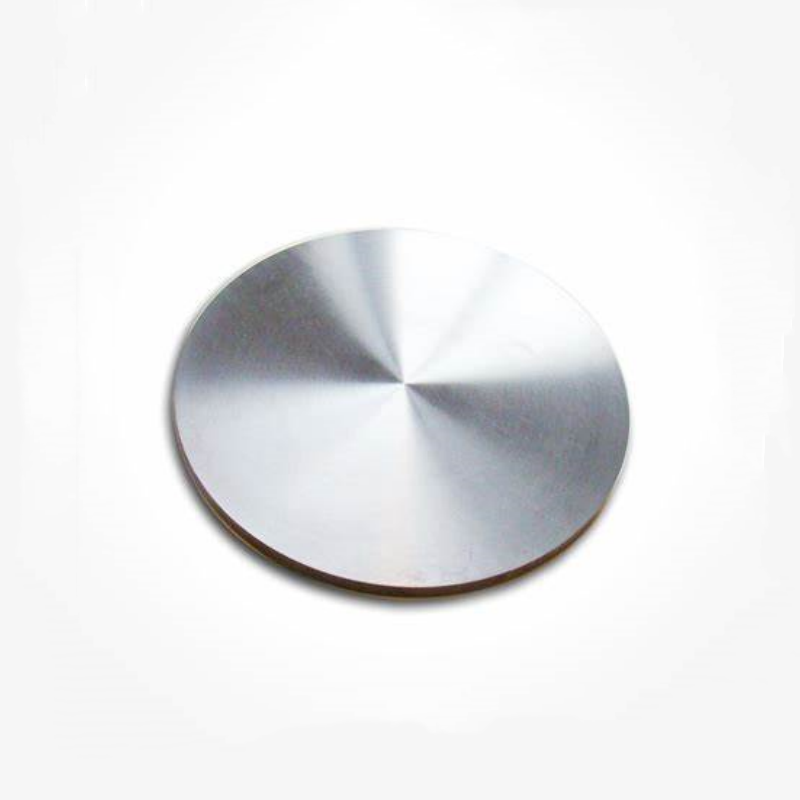

WNiFe (Tungsten Nickel Iron High-Density Alloy Round Bar) is a high-performance material known for its exceptional density, strength, and corrosion resistance. This alloy is widely used in various industries, including aerospace, defense, and medical, where it serves in critical components exposed to demanding environments. Its unique properties make it ideal for applications requiring durability, reliability, and high performance.

Product Overview

WNiFe (Tungsten Nickel Iron High-Density Alloy Round Bar) is a heavy alloy based on tungsten, with the addition of nickel and iron, offering exceptionally high density, strength, and good plasticity. The density of this alloy typically ranges from 16.0-18.5 g/cm³, providing excellent thermal and electrical conductivity as well as radiation absorption capabilities. Manufactured using powder metallurgy, this alloy is widely used in various high-performance engineering and industrial applications.

Features

- High Density and Strength: With a density of 16.0-18.5 g/cm³ and tensile strength ranging from 700-1000 MPa, WNiFe alloy is designed for high-load applications.

- Excellent Electrical and Thermal Conductivity: It offers good electrical conductivity, making it suitable for lighting and welding industries. Its thermal conductivity is five times that of tool steels.

- Superior Radiation Absorption: WNiFe alloy can effectively absorb gamma rays and X-rays, with absorption capabilities 30-40% greater than lead.

- Low Thermal Expansion Coefficient: The coefficient of thermal expansion is only 1/2 to 1/3 of that of iron or steel, making it ideal for high-precision applications.

- Good Weldability and Machinability: This alloy is easy to weld and process, adapting to a wide range of manufacturing needs.

Applications

- Counterweights and Balancing Hammers: Used in aerospace, aviation, and mechanical manufacturing for counterweights and dynamic balancing.

- Radiation Shielding: Commonly used in the production of radiation shielding components for medical and nuclear energy equipment.

- Aerospace: Applied in critical components such as gyroscope rotors, guidance devices, and vibration dampers.

- Mechanical Manufacturing: Ideal for high-strength parts like die-casting molds, tool holders, and boring bars.

- Military Applications: Used in manufacturing projectiles, rivet heads, switch contacts, and other military components.

new material

new material