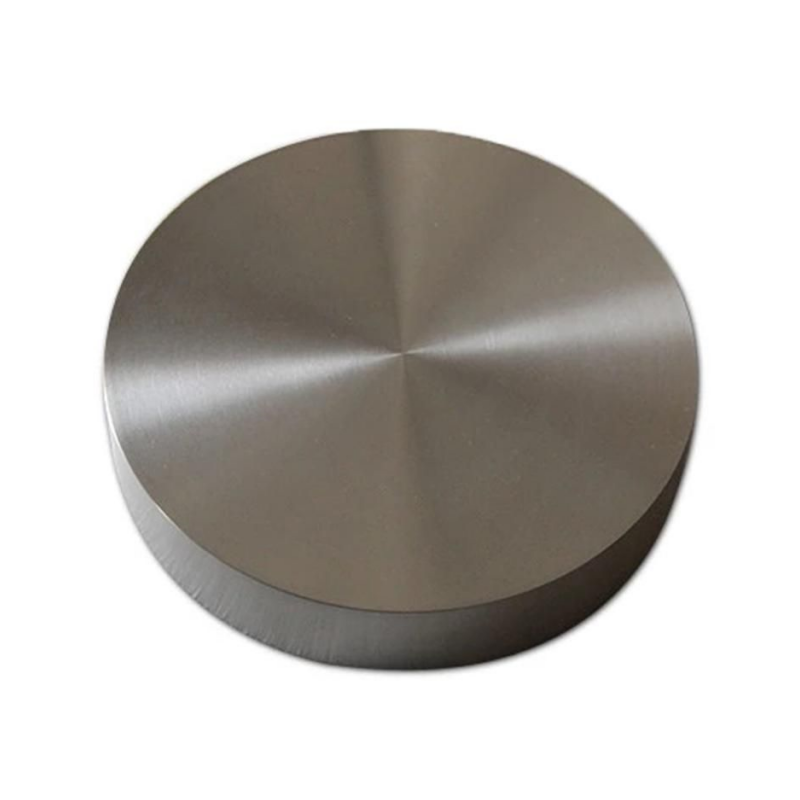

Titanium carbonitride (TiCN) powder is an advanced ceramic material featuring exceptional hardness, wear resistance, and thermal stability. It is widely used in cutting tools, coatings, powder metallurgy, and industrial manufacturing. The combination of titanium, carbon, and nitrogen provides enhanced mechanical properties, making TiCN an ideal material for applications requiring superior durability and performance.

Product Overview

Titanium carbonitride (TiCN) is a high-performance coating material superior to regular titanium nitride (TiN), commonly used to enhance the performance of milling, forming, and punching tools. It possesses high hardness, high melting point, and excellent oxidation resistance, providing outstanding wear resistance and toughness during cutting and forming processes. Compared to titanium carbide (TiC), TiCN features a lower friction coefficient, significantly improving the quality and lifespan of coated tools.

Product Features

- High Hardness and Wear Resistance:TiCN offers extreme hardness and wear resistance, making it suitable for high-speed cutting and machining.

- Low Friction Coefficient:With a lower friction coefficient compared to titanium carbide, it reduces tool wear and extends tool life.

- Oxidation Resistance:TiCN demonstrates excellent oxidation resistance, making it suitable for high-temperature and high-stress environments.

- Good Ductility and Lubricity:Provides better lubrication during high-stress cutting, enhancing tool performance.

- Improved Tool Performance:Enhances tool stability and cutting efficiency under high-stress conditions.

Applications

- Cutting Tools:Used as a coating for milling, forming, and punching tools to improve wear resistance and toughness.

- Metalworking:Applied in the machining of steel, hard-to-machine steel alloys, and highly abrasive or sticky materials like cast iron, brass, and aluminum alloys.

- Mechanical Components:Used in wear-resistant mechanical parts and welding materials to extend product life.

- High-Speed Machining:Suitable for high-feed rate and high-speed cutting applications, improving production efficiency.

- Metallurgy and Ceramic Coatings:Used in metallurgy and metal-ceramic coatings to enhance surface properties.

| brand | Chemical Composition % | |||||

| total carbon | Free carbon | N | O | Fe | FSSS(μm) | |

| TiCN-1 | 8.0-9.5 | ≤0.3 | 12.0-13.5 | ≤0.5 | ≤0.2 | ≤0.5 |

| TiCN-2 | 9.5-10.5 | ≤0.3 | 10.8-11.8 | ≤0.6 | ≤0.2 | ≤0.5 |

| size | -250 mesh, -325 mesh, -400 mesh. | |||||

| packing | 1 kg / vacuum bags, 100 kg / barrel. | |||||

| Uses | used for cutting tools and wear-resistant mechanical parts. | |||||

new material

new material