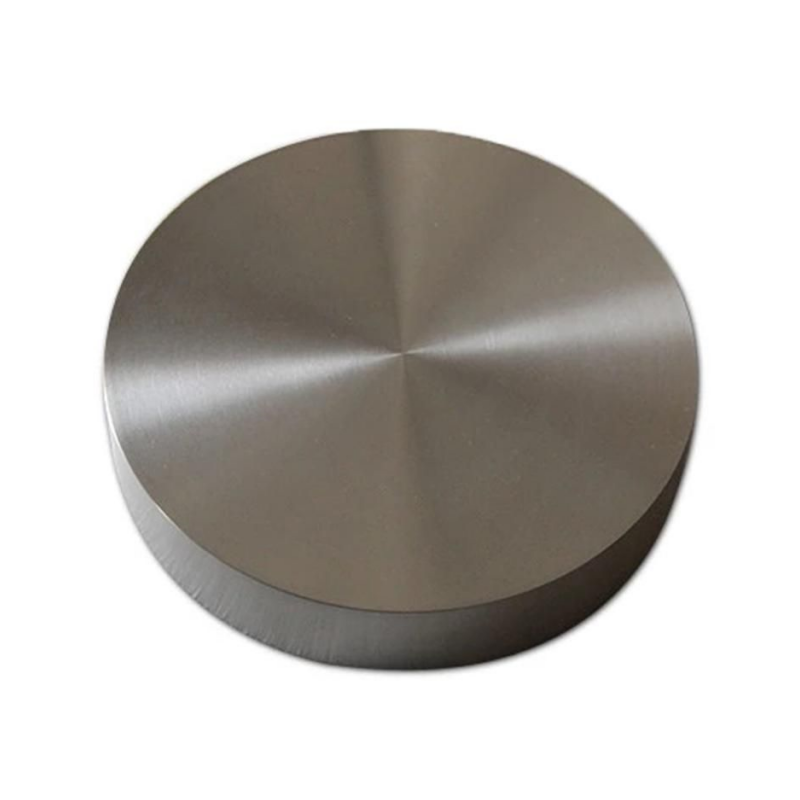

Titanium-Aluminum Alloy is a high-performance material known for its excellent strength-to-weight ratio, corrosion resistance, and high-temperature stability. This alloy is widely used in various industries, including aerospace, automotive, and industrial applications, where it serves in critical components exposed to demanding environments. Its unique properties make it ideal for applications requiring lightweight durability and high performance.

Product Overview

Titanium-aluminum alloy is an intermetallic compound known for its light weight, high strength, oxidation resistance, and heat resistance. It is widely used in high-temperature, high-performance fields. The most notable form is Gamma TiAl, which maintains excellent oxidation resistance and corrosion resistance at temperatures exceeding 600°C. Titanium-aluminum alloy shows great potential in aerospace and automotive industries, especially in improving the thrust-to-weight ratio of aircraft engines.

Product Features

- Lightweight and High Strength:Titanium-aluminum alloy offers a lighter weight with excellent strength, making it ideal for high-performance materials where weight reduction is crucial.

- High-Temperature Performance:It retains stable oxidation resistance and corrosion resistance in high-temperature environments.

- Corrosion Resistance:The alloy exhibits strong corrosion resistance even in harsh environments.

- Low Ductility:While it has lower ductility, its outstanding high-temperature performance and mechanical properties compensate for this limitation.

Applications

- Aerospace Industry:Used primarily in aircraft engines and other aerospace components, enhancing engine thrust-to-weight ratio and improving high-temperature performance.

- Automotive Industry:Applied in automotive engines and other high-temperature components to increase heat resistance and corrosion resistance.

- High-Performance Materials:Used in high-temperature and high-pressure environments, particularly in aerospace, aviation, and automotive industries, to meet demanding performance requirements.

| Brand | Chemical Composition % | |||

| Ti | Al | Fe | Si | |

| Ti10Al90 | 10+-2% | Margin | 0.2 | 0.5 |

| Ti60Al40 | 60+-2% | Margin | 0.2 | 0.5 |

| Ti50Al50 | 50+-2% | Margin | 0.2 | 0.5 |

| size | 60 mesh, 80 mesh, 200 mesh. Or on-demand processing | |||

| packing | 1 kg / vacuum aluminum foil bags, 100 kg / barrel. | |||

| Uses | mainly used in the manufacture aviation equipment, daily necessities, building doors and windows | |||

new material

new material