TiNbMoTiW High Entropy Alloy (Titanium-Niobium-Molybdenum-Tungsten) is a cutting-edge material known for its remarkable combination of mechanical properties, including high strength, excellent ductility, and superior high-temperature stability. This alloy is widely used in advanced industries such as aerospace, automotive, and energy, where it is employed in critical components exposed to extreme environments. Its unique multi-principal element composition allows for unparalleled performance in demanding applications, making it a top choice for innovative engineering solutions.

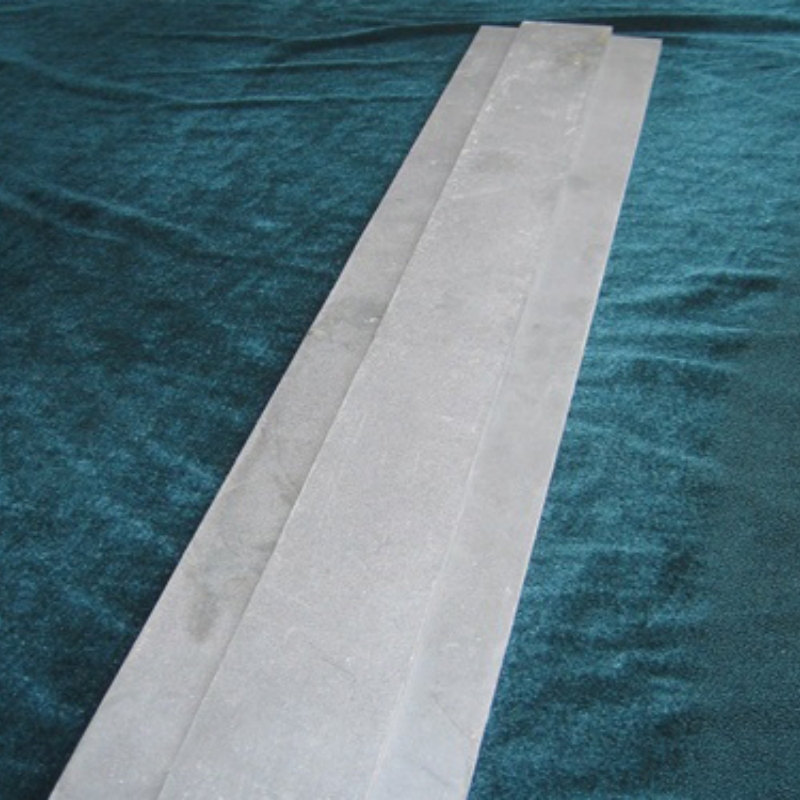

Product Overview

TiNbMoTiW high entropy alloy is a novel material composed of five metal elements in equal or near-equal proportions. This high entropy alloy offers exceptional high-temperature performance, outstanding fracture toughness, and superior corrosion resistance. Unlike traditional alloys, high entropy alloys exhibit stronger stability and versatility, making them ideal for applications in extreme environments. The alloy's unique composition and structure enable it to maintain excellent performance under high, low, and corrosive conditions.

Key Features

- Multi-principal Element Alloy:Composed of five metals, ensuring excellent overall performance and suitability for a wide range of extreme environments.

- High-Temperature Performance:Exhibits remarkable stability and durability at high temperatures, making it ideal for high-temperature applications such as engine components.

- Good Fracture Toughness:Maintains excellent mechanical properties, even under extremely low temperatures or harsh conditions.

- Corrosion Resistance:Superior to traditional alloys in terms of corrosion resistance, especially in aggressive and harsh environments.

- Amorphous Metal Properties:Can be processed into amorphous metals, exhibiting increased strength, hardness, toughness, and specialized magnetic properties.

Applications

- High-Temperature Applications:Perfect for use in aerospace, engine components, and other high-temperature environments where material stability and performance are crucial.

- Low-Temperature Applications:Demonstrates excellent fracture toughness in extreme cold, making it ideal for use in cryogenic equipment and environments such as deep-sea or Arctic applications.

- Corrosion-Resistant Applications:Used in harsh chemical, marine, and industrial environments, offering superior corrosion resistance compared to traditional materials.

- Amorphous Metal Applications:Can be applied in electronics, aerospace, and other high-tech fields, particularly where materials require high strength, wear resistance, and special magnetic properties.

new material

new material