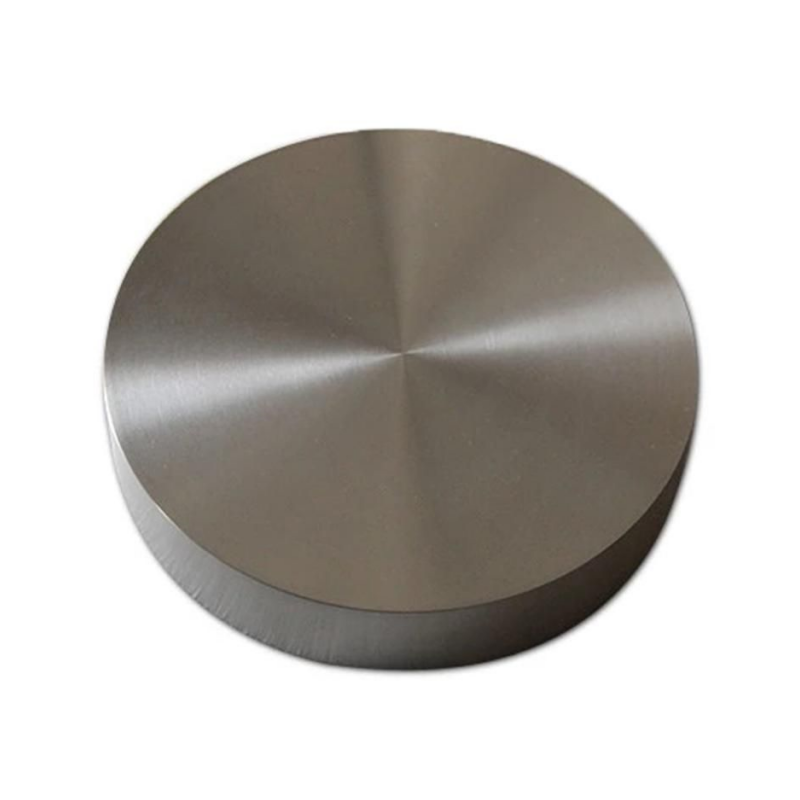

Iron Vanadium Alloy is a high-performance material known for its excellent strength, toughness, and corrosion resistance. This alloy is widely used in various industries, including aerospace, automotive, and manufacturing, where it serves in critical components exposed to demanding environments. Its unique properties make it ideal for applications requiring durability, reliability, and high performance.

Product Overview

Iron Vanadium Alloy is a combination of iron and vanadium, with vanadium content typically ranging from 35% to 85%. As a universal hardening agent and strengthening agent, iron vanadium alloy is widely used in the alloying of steel products, particularly in high-strength low-alloy steels, tool steels, and other specialty steels. The alloy not only enhances the tensile strength, hardness, and corrosion resistance of steel but also provides significant corrosion protection.

Product Features

- Enhanced Strength:Iron vanadium alloy significantly increases the tensile strength and hardness of steel.

- Corrosion Resistance:Effectively improves the corrosion resistance of steel in alkaline reagents, sulfuric acid, and hydrochloric acid.

- Improved Strength-to-Weight Ratio:Helps enhance the strength-to-weight ratio of materials, improving performance in various applications.

- High Vanadium Content:With vanadium content up to 85%, it has excellent alloying effects, making steel more durable and resistant to wear and fatigue.

Applications

- Steel Alloying:Used as an alloying agent to enhance the properties of steel.

- Tool Steel and High-Strength Steel:Commonly used in the production of tool steel, railway track steel, and other high-strength steels.

- Automotive and Oilfield Pipe Steel:Employed in the production of forged crankshafts for automobiles, oilfield pipe steel, and other critical components.

- Corrosion Protection:Improves the corrosion resistance of steel, particularly in environments with acidic or alkaline reagents.

- Performance Enhancement of Materials:Widely used to reinforce steel and other iron-based products to improve mechanical properties and extend service life.

| Brand | Chemical Composition % | ||||||

| V | C | Si | P | S | Al | Mn | |

| ≥ | ≤ | ||||||

| FeV50-A | 48.0-55.0 | 0.4 | 2 | 0.06 | 0.04 | 1.5 | – |

| FeV50-B | 48.0-55.0 | 0.6 | 2.5 | 0.1 | 0.05 | 2 | – |

| FeV80-A | 78.0-82.0 | 0.15 | 1.5 | 0.05 | 0.04 | 1.5 | 0.5 |

| FeV80-B | 78.0-82.0 | 0.2 | 1.5 | 0.06 | 0.05 | 2 | 0.5 |

| size | -40 mesh, -60 mesh, or on-demand processing. | ||||||

| packing | 25 kg / bag, 100 kg / drum, 1 ton / bag. | ||||||

| Uses | mainly used as an alloying agent in steel. | ||||||

new material

new material