GH3625 High-Temperature Alloy is a nickel-based superalloy widely used in aerospace, chemical processing, and power generation industries. It offers exceptional corrosion and oxidation resistance, excellent thermal stability, and outstanding mechanical properties, making it ideal for critical components like turbine blades, heat exchangers, and chemical reactors operating under extreme conditions.

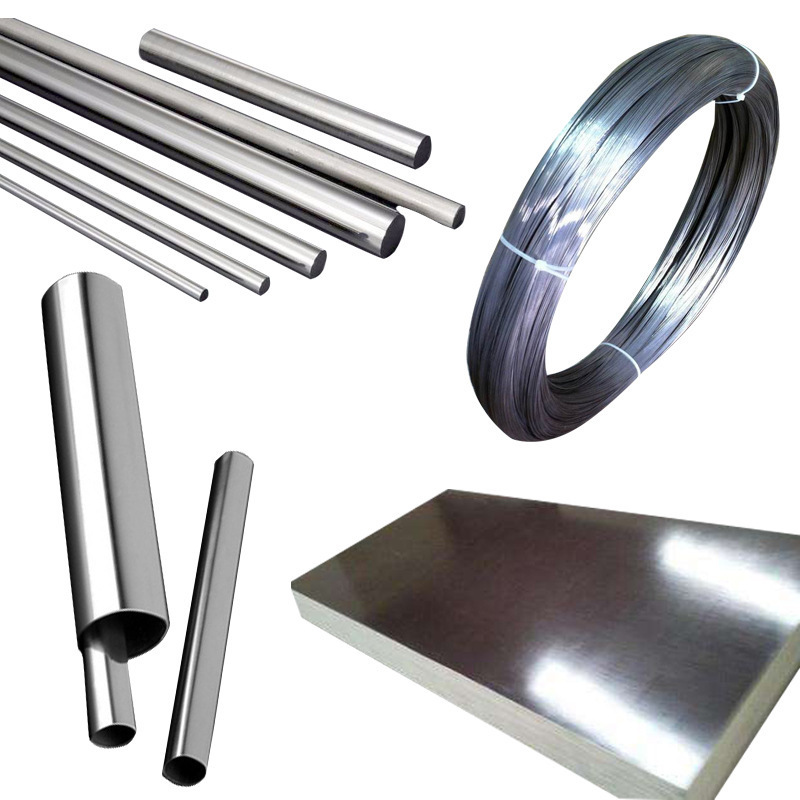

Product Overview

GH3625 is a nickel-based high-temperature alloy primarily strengthened by molybdenum and niobium. This alloy offers excellent corrosion and oxidation resistance, making it suitable for a wide temperature range from low temperatures up to 980°C. It demonstrates excellent tensile and fatigue strength, particularly exhibiting outstanding stress corrosion resistance in salt spray environments. GH3625 also provides excellent machining and welding performance, making it ideal for aerospace, aviation, and chemical industries, where high temperature and corrosive environments are common.

Key Features

- Corrosion and Oxidation Resistance: Excellent corrosion and oxidation resistance across a wide temperature range (low temperatures to 980°C), making it ideal for harsh environments.

- Excellent Tensile and Fatigue Strength: The alloy offers superior tensile strength and fatigue resistance, making it suitable for high-stress applications.

- Stress Corrosion Resistance: Particularly resistant to stress corrosion, especially in salt spray environments.

- Good Machining and Welding Properties: GH3625 has excellent cold and hot working properties, making it suitable for forging, rolling, welding, and other manufacturing processes.

Applications

- Aerospace Engines: Used to manufacture high-stress, high-temperature parts for aerospace engines.

- Spacecraft Structural Components: Widely used in aerospace applications where high temperature and corrosion resistance are critical.

- Chemical Equipment: Suitable for components in chemical equipment exposed to high-temperature, corrosive environments.

- High-Temperature Operating Environments: Ideal for high-temperature parts working in severe conditions, ensuring reliability and performance.

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | Cu≥ |

| 0.1 | 0.5 | 0.5 | 0.015 | 0.015 | 20.0-2300 | Allowance | 8.0-10 | 0.07 |

| other | N≤ | Al≤ | Ti≤ | Fe≤ | Co≤ | V< | W≤ | Nb≤ |

| 0.4 | 0.4 | 5 | 1 |

new material

new material