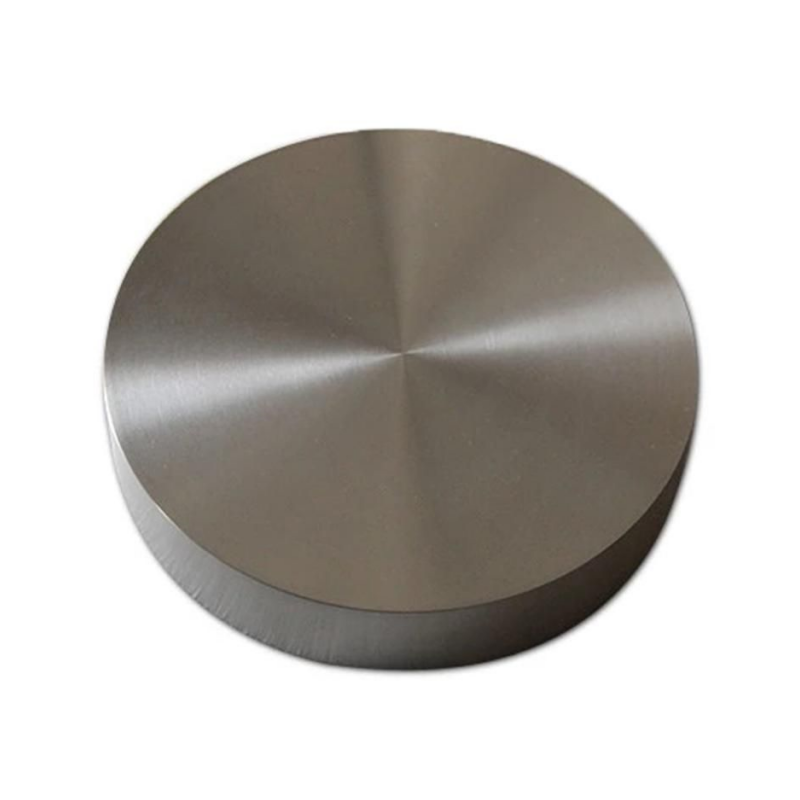

Bismuth bars are high-purity metal products known for their non-toxic, environmentally friendly properties and unique physical characteristics. With a low melting point and high density, bismuth is widely used in alloy production, medical applications, electronic components, and specialty coatings. It is also valued in research and industrial applications for its crystalline structure and ease of handling.

Product Overview

P-type and N-type Bismuth Bars (Bi₂Te₃) are made from high-purity bismuth telluride materials, which are widely used in thermoelectric applications, particularly in thermoelectric cooling and power generation systems. These bismuth bars offer excellent thermoelectric properties, making them ideal for use in cooling systems and energy recovery systems. Their stable chemical properties and efficient thermoelectric conversion capabilities make them a crucial material in the electronics and energy industries.

Features

- High Purity (4N): Ensures excellent thermoelectric performance

- Stable Chemical Properties: With good electrical conductivity and stability

- High-Efficiency Thermoelectric Conversion: Ideal for both cooling and power generation

- Customizable: Specifications and dimensions can be tailored to meet client requirements

Applications

- Thermoelectric Cooling: Used in thermoelectric cooling systems, widely applied in electronic device cooling and temperature control

- Energy Recovery: Converts waste heat into electrical energy, used in thermoelectric power generation systems

- Electronics Industry: Used in electronic component cooling and temperature management

- Aerospace: Applied in spacecraft and satellite thermal control systems

- Research & Development: Essential for the study and development of high-performance thermoelectric materials

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | <0.01 | ppm | Zn | <0.05 | ppm | Pb | |||||

| B | 0.22 | ppm | Ga | Bi | Matrix | wt% | |||||

| F | <1 | ppm | Ge | Y | |||||||

| Na | <0.01 | ppm | As | Th | |||||||

| Mg | Se | <0.01 | ppm | Er | |||||||

| Al | <0.01 | ppm | Zr | <0.01 | ppm | Ru | |||||

| Si | Nb | <0.01 | ppm | Rh | |||||||

| P | 0.08 | ppm | Mo | <0.01 | ppm | Os | |||||

| Cl | Pd | <0.01 | ppm | Cd | |||||||

| K | <0.05 | ppm | Ag | <0.01 | ppm | In | |||||

| Ca | <0.05 | ppm | Sn | ||||||||

| Ti | <0.05 | ppm | Sb | <0.05 | ppm | ||||||

| V | <0.05 | ppm | Ba | ||||||||

| Cr | <0.01 | ppm | Hf | ||||||||

| Mn | <0.05 | ppm | Ta | C | |||||||

| Fe | <0.01 | ppm | W | S | |||||||

| Co | <0.05 | ppm | Pt | O | |||||||

| Ni | <0.01 | ppm | Au | N | |||||||

| Cu | Hg | H |

new material

new material