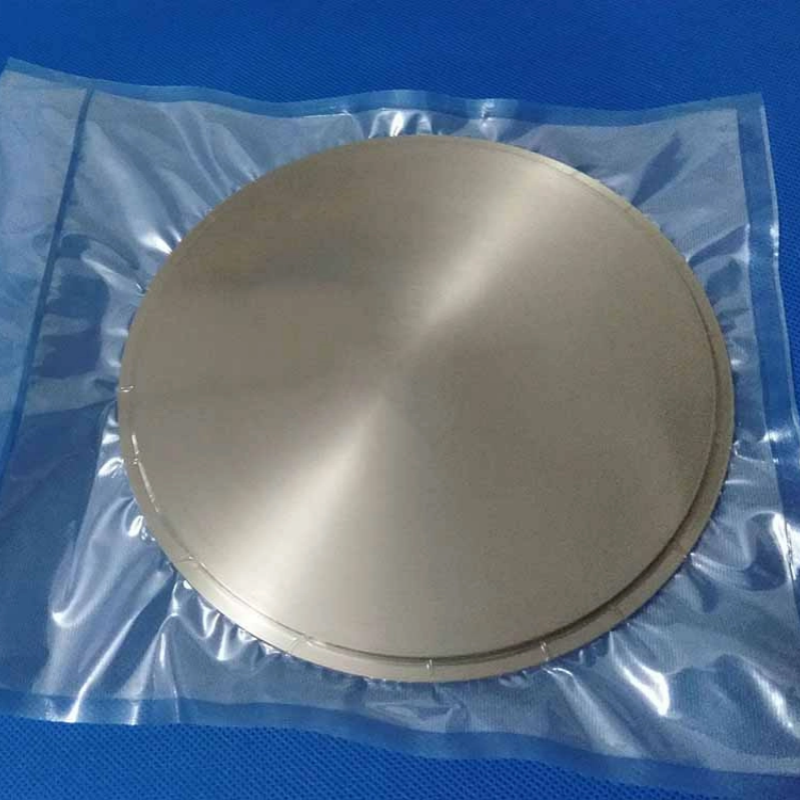

Aluminum-yttrium alloy (ALY5) is an advanced metallurgical material recognized for its superior oxidation resistance, mechanical durability, and thermal stability. The incorporation of yttrium enhances grain refinement, corrosion protection, and structural integrity, making it an essential material in aerospace components, high-temperature industrial applications, and precision manufacturing. Aluminum-yttrium alloy plays a crucial role in sustainable material solutions and high-performance engineering.

Product Overview

Aluminum yttrium alloy (ALY5) contains 4–6% yttrium and is specifically designed to improve plasticity and overall alloy performance. The addition of yttrium effectively enhances the strength, toughness, and oxidation resistance of aluminum alloys, while also improving their high-temperature and corrosion resistance. This alloy is suitable for industrial applications requiring excellent overall performance and high-temperature stability, with good machinability that allows for customization to meet various application needs.

Key Features

- The yttrium content (4–6%) significantly improves the alloy's strength, toughness, and high-temperature performance.

- Enhances oxidation resistance and corrosion resistance, extending the service life of the alloy.

- Good plasticity and machinability, allowing for customization into various shapes based on customer requirements.

- Maintains excellent stability in high-temperature and high-stress environments.

- Improves wear resistance, making it suitable for long-term use in demanding conditions.

Applications

- Aerospace:Used for manufacturing high-strength, high-temperature components in aircraft, especially in extreme temperature environments.

- Automotive Industry:Widely used in automotive engine and transmission system components, as well as other high-temperature, high-stress parts.

- Metallurgical Industry:Used in high-temperature components for metallurgical equipment, ensuring stable performance under high pressure and temperature conditions.

- Electronics Industry:Used to manufacture high-strength, corrosion-resistant electronic components and high-performance devices.

- Chemical Industry:Suitable for chemical reaction equipment and pipelines that require high-temperature and corrosion resistance, improving equipment reliability and service life.

new material

new material