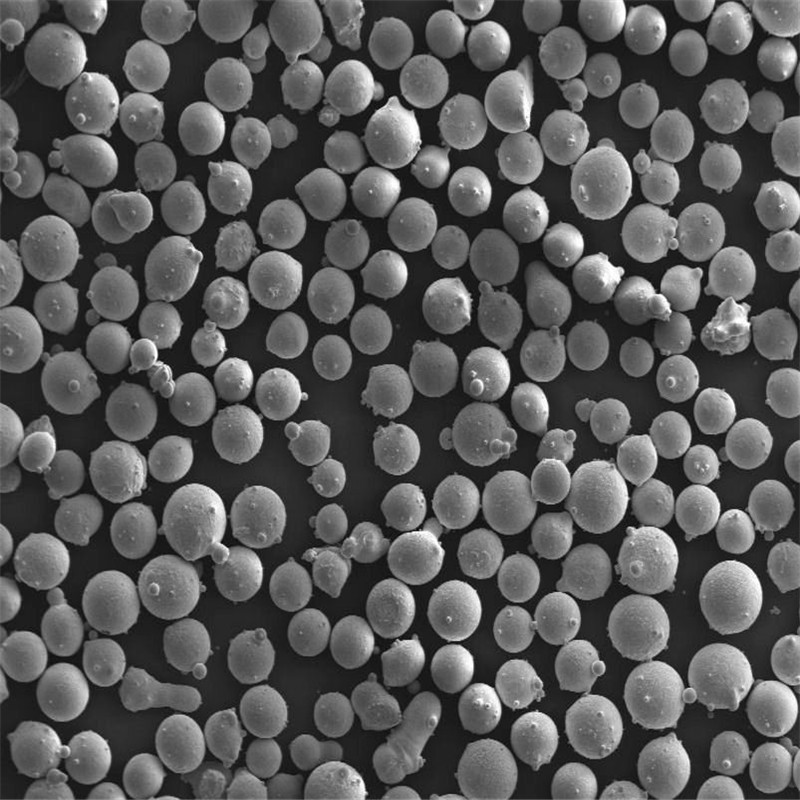

15-5PH Stainless Steel Powder is a martensitic precipitation-hardening stainless steel powder, commonly used in aerospace, automotive, and engineering industries. It features excellent corrosion resistance, high strength, and good toughness, making it ideal for additive manufacturing, metal injection molding, and advanced engineering applications requiring high-performance materials.

Product Overview

15-5PH Stainless Steel Powder is a precipitation hardening stainless steel alloy powder containing niobium and copper. It boasts excellent mechanical properties and strong corrosion resistance. This powder is widely used in manufacturing applications requiring high strength and hardness, especially in aerospace, chemical engineering, and high-temperature environments. With its superior mechanical performance and good processability, 15-5PH stainless steel powder is extensively used in metal 3D printing and other precision manufacturing processes.

Product Features

- High Strength and Hardness:Offers exceptional mechanical properties, suitable for high-strength applications.

- Excellent Corrosion Resistance:Outstanding corrosion resistance, making it ideal for use in harsh environments.

- Precipitation Hardening:The material undergoes precipitation hardening, providing excellent processability and toughness.

- Good Machinability:Easy to process and manufacture, ideal for producing complex-shaped parts.

- High-Temperature Resistance:Capable of withstanding higher temperature environments, suitable for high-temperature working conditions.

Applications

- Aerospace:Used in manufacturing components for aircraft engines and structural parts, especially in high-strength and corrosion-resistant environments.

- Chemical Engineering:Suitable for high-strength parts in chemical equipment, such as pumps, valves, and reactors.

- Medical Devices:Used to produce medical instruments and implants that require high corrosion resistance.

- Automotive Manufacturing:Ideal for high-strength components, particularly in high-temperature and corrosive environments.

new material

new material