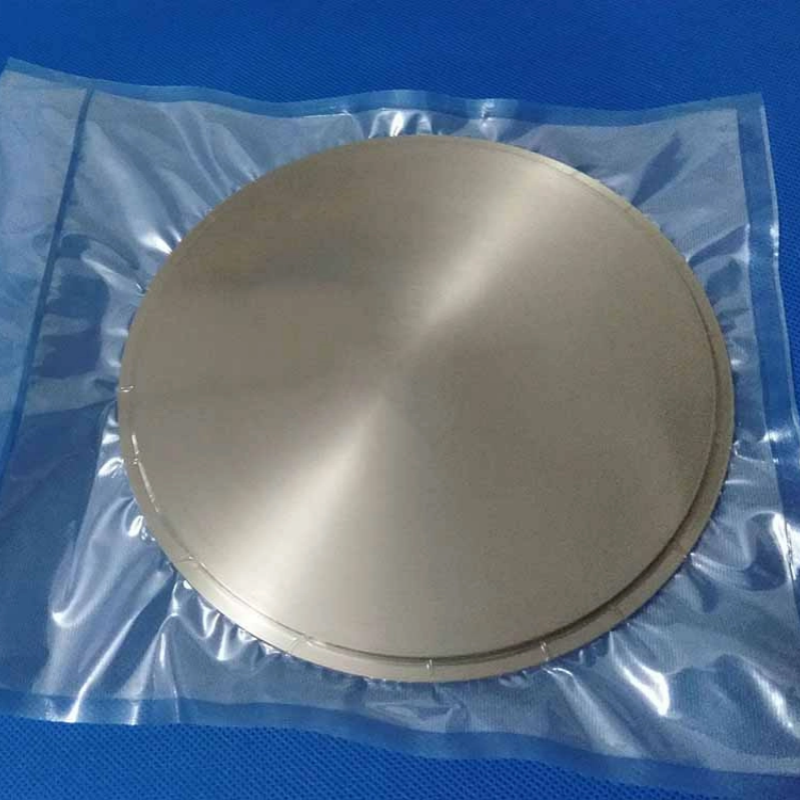

Zirconium Silicon Iron Alloy (Zr-Si-Fe) is a high-performance material known for its excellent mechanical properties, corrosion resistance, and high-temperature stability. This alloy is widely used in various industries, including aerospace, automotive, and chemical processing, where it serves in critical components exposed to demanding environments. Its unique properties make it ideal for applications requiring durability, strength, and reliability.

Product Overview

Zirconium Silicon Iron Alloy is a compound alloy consisting of zirconium, silicon, and iron, possessing unique chemical properties. This alloy is commonly used in the production of alloy steels, where it significantly enhances the high-temperature performance, oxidation resistance, and other characteristics of the alloy. As an alloying agent or additive, zirconium silicon iron alloy optimizes material properties and finds applications across industries, including cast iron, steel, and other specialized metal alloys.

Product Features

- High-Temperature Resistance:Improves the high-temperature performance of alloys, suitable for applications in high-temperature environments.

- Enhanced Alloy Properties:Acts as an additive to effectively increase alloy hardness, strength, and corrosion resistance.

- Versatile Alloying Agent:Can improve the melting point and fluidity of alloys, offering good machinability.

- Good Magnetism and Electrical Conductivity:Exhibits excellent magnetic properties and electrical conductivity in magnetic alloy applications.

Applications

- Cast Iron Balling Agent & Alloy Additive:Used as an additive in the production of cast iron balls and other alloy materials.

- Alloy Steels & High-Temperature Alloys:Enhances alloy steels and high-temperature alloys, particularly in environments requiring heat resistance and corrosion resistance.

- Titanium Alloys & Magnetic Alloys:Utilized in the production of titanium alloys and magnetic alloys to enhance their performance.

- Aluminum Alloys:Serves as an alloying agent in aluminum alloys, improving their mechanical properties and durability.

| Brand | Chemical Composition % | ||||

| Zr | Si | C | S | P | |

| ≤ | |||||

| Zr50SiFe | 45-55 | 35-40 | 0.2 | 0.05 | 0.05 |

| Zr40SiFe | 35-45 | 42-55 | 0.2 | 0.05 | 0.05 |

| Zr30SiFe | 35-38 | 40-55 | 0.2 | 0.05 | 0.05 |

| size | -60 -80 mesh or on demand processing, | ||||

| packing | 25 kg / bag, 1 ton / bag | ||||

| Usage | cast iron ball agent, alloy additives. | ||||

new material

new material