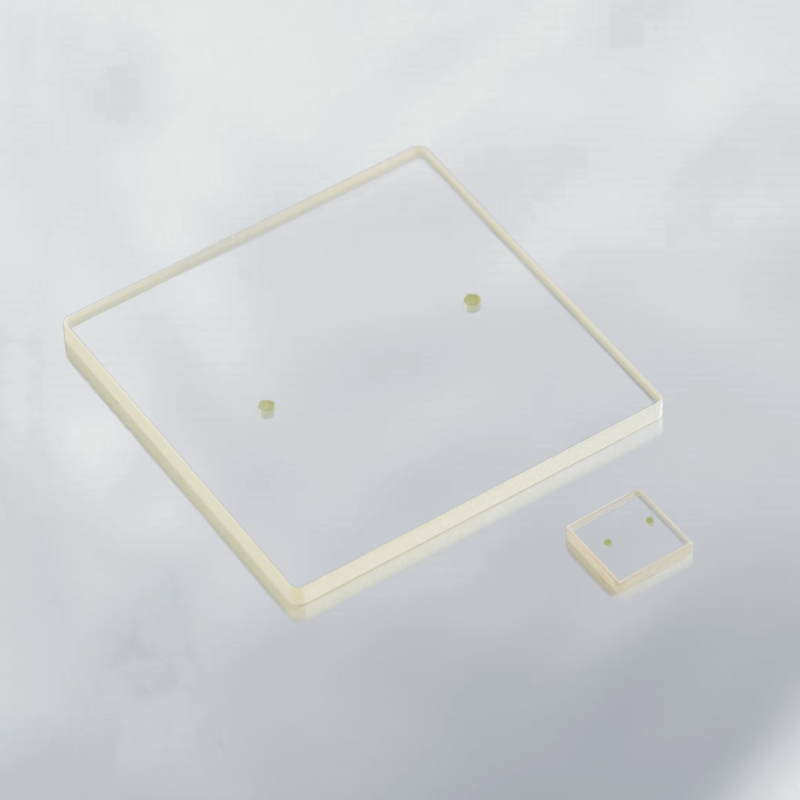

Zinc sulfide window plate with a rectangular aperture is a high-performance optical component designed for exceptional infrared transmission, mechanical durability, and chemical stability. Manufactured from ZnS, it offers excellent optical clarity and resistance to environmental degradation, making it ideal for infrared imaging, aerospace technologies, laser systems, and precision scientific instrumentation. Its robust structure ensures reliable performance in demanding optical applications.

Product Overview

The zinc sulfide rectangular aperture window plate is an optical component made from high-purity zinc sulfide material, with a precisely cut rectangular aperture. It is widely used in various optical systems to control light beam transmission, focusing, and imaging. This window plate boasts high transmittance, excellent anti-reflection properties, and outstanding thermal stability, with high transmittance and low reflectance in both visible and infrared wavelengths. It is ideally suited for applications in LiDAR, optical sensors, spectrometers, and other optical equipment. Zinc sulfide offers excellent optical performance, particularly in harsh environments, ensuring stable and reliable optical performance.

Key Features

- High Transmittance: Zinc sulfide window plates exhibit high transmittance in the visible and infrared spectrum, ensuring efficient light signal transmission and the smooth operation of optical systems.

- High Anti-Reflection Properties: Zinc sulfide has a low reflection rate, reducing optical losses and enhancing system transmission efficiency.

- Excellent Thermal Stability: With outstanding thermal stability, zinc sulfide can maintain its performance in high-temperature environments, making it suitable for various high-temperature and harsh environmental applications.

- Customizable Rectangular Aperture: The size and shape of the rectangular aperture can be customized to meet specific optical system requirements for light beam shape and size.

- Superior Infrared Optical Performance: Zinc sulfide is a leading infrared optical material, offering significant advantages in infrared imaging and spectral applications.

Applications

Zinc sulfide rectangular aperture window plates are widely used in various optical systems, especially where precise beam control and stable performance are required:

- Laser Systems: Used as an optical component for laser beam transmission and collimation.

- Optical Sensors: Serves as a protective window for optical sensors, enhancing the efficiency of light signal transmission.

- Spectrometers: Acts as a transmissive or reflective element in spectrometers, aiding in spectral analysis.

- Infrared Optical Systems: Exceptional performance in infrared imaging and infrared spectroscopy, widely used in infrared optical equipment.

- High-Power Laser Systems: Due to its high laser damage threshold, zinc sulfide window plates are commonly used in high-power laser systems, providing stable performance and longevity.

| Physical Property | CVD Zinc Sulfide | Multispectral CVD Zinc Sulfide |

| Density | 4.09 g/cm³ | 4.09 g/cm³ |

| Resistivity | ~10¹² Ω·cm | ~10¹¹ Ω·cm |

| Melting Point | 1827 ℃ | - |

| Chemical Purity | 100.00% | 100.00% |

| Thermal Expansion | 6.6×10⁻⁶ @ 273K | 6.3×10⁻⁶ @ 273K |

| 7.3×10⁻⁶ @ 373K | 7.0×10⁻⁶ @ 373K | |

| Thermal Conductivity | 16.7 W/(m·K) @ 298K | 27.2 W/(m·K) @ 298K |

| Specific Heat Capacity | 0.469 J/(g·K) @ 298K | 0.515 J/(g·K) @ 298K |

| Knoop Hardness | 200-235 kg/mm² | 160 kg/mm² |

| Bending Strength | 103 MPa | - |

| Young's Modulus | 74.5 GPa | 74.5 GPa |

| Poisson's Coefficient | 0.29 | 0.29 |

| Optical Property | CVD Zinc Sulfide | Multispectral CVD Zinc Sulfide |

| Transmission Range | 1-14 μm | 0.37-14 μm |

| Refractive Index Inhomogeneity | <7.3×10⁻⁴ @ 10.6μm | <0.2×10⁻⁴ @ 632.8nm |

| Absorption Coefficient | 0.2 /cm @ 10.6μm | 0.2 /cm @ 10.6μm |

| Thermal Light Coefficient | 4.6×10⁻⁵ @ 1150nm | 5.43×10⁻⁵ @ 632.8nm |

| 4.3×10⁻⁵ @ 3390nm | 4.21×10⁻⁵ @ 1150nm | |

| 4.1×10⁻⁵ @ 10.6μm | 3.87×10⁻⁵ @ 3390nm |

| CVD Zinc Sulfide - Refractive Index and Wavelength | |||

| Wavelength (nm) | Refractive Index (n) | Wavelength (nm) | Refractive Index (n) |

| 620 | 2.355 | 9800 | 2.203 |

| 1000 | 2.292 | 10600 | 2.192 |

| 3800 | 2.253 | 11400 | 2.18 |

| 5000 | 2.246 | 12200 | 2.167 |

| 7000 | 2.232 | 13800 | 2.132 |

| 9000 | 2.212 | 14200 | 2.126 |

| Multispectral CVD Zinc Sulfide - Refractive Index and Wavelength | |||

| Wavelength (nm) | Refractive Index (n) | Wavelength (nm) | Refractive Index (n) |

| 400 | 2.545 | 8000 | 2.223 |

| 1010 | 2.292 | 9000 | 2.213 |

| 2060 | 2.264 | 10000 | 2.201 |

| 3500 | 2.255 | 11250 | 2.183 |

| 4500 | 2.25 | 12000 | 2.171 |

| 5000 | 2.247 | 13000 | 2.153 |

| Property | Value |

| Diameter Range | 2-300mm |

| Focal Length | 15-5000mm |

| Thickness | 0.12-60mm |

| Surface Quality | 80-50, 60-40, 40-20, 20-10, 10-5 |

| Surface Flatness | λ/2, λ/4, λ/8, λ/10 |

| Clear Aperture | >90% |

| Coating | Customizable |

new material

new material