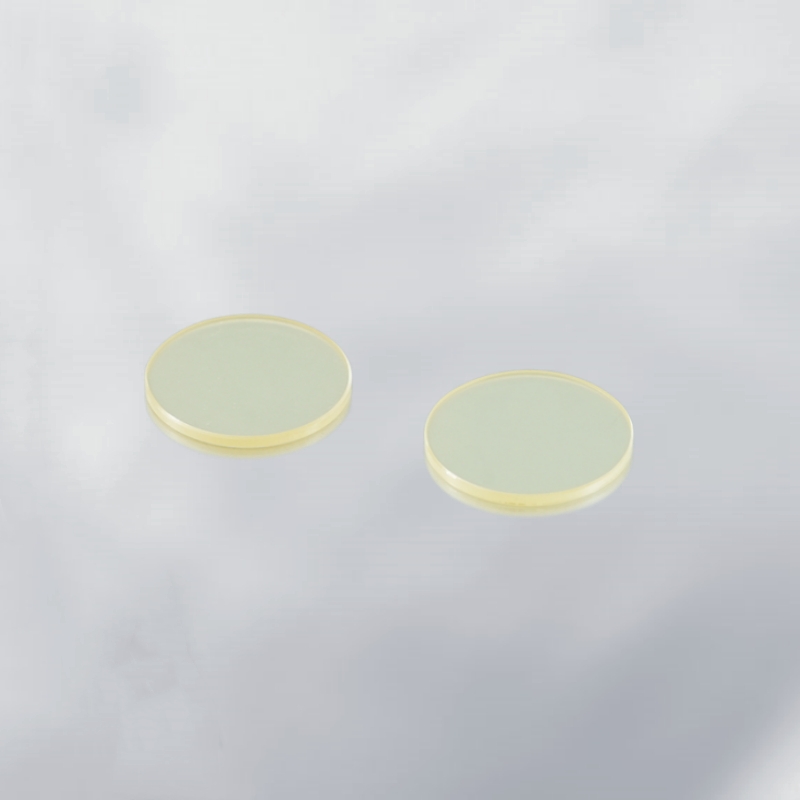

Zinc sulfide circular window is a high-performance optical component designed for superior infrared transmission, excellent mechanical durability, and chemical stability. Manufactured from high-purity ZnS, it provides outstanding optical clarity, minimal absorption, and resistance to environmental degradation, making it an essential material for infrared imaging systems, laser optics, aerospace applications, and precision scientific instruments. Its ability to withstand harsh conditions ensures reliable performance in demanding optical environments.

Product Overview

Zinc Sulfide circular windows are optical elements made from zinc sulfide material, widely used to protect the internal components of optical systems from external environmental influences. These windows offer high transparency, low absorption, and low scattering, allowing effective transmission of visible and infrared light. Zinc Sulfide is especially suitable for systems involving visible light and mid- to long-wave infrared sensors. Additionally, its hardness and impact-resistant properties ensure stable optical performance even in harsh environments.

Key Features

- High Transparency: Excellent light transmission in both visible and infrared wavelengths, suitable for a wide range of optical applications.

- Low Absorption and Scattering: Zinc Sulfide has low light absorption and scattering, effectively improving the efficiency of optical systems.

- Hard and Impact-Resistant: With good mechanical strength, Zinc Sulfide can withstand certain impacts, enhancing the durability of optical systems.

- Wide Band Transmission: Stable performance across a wide transmission range (0.4 - 12μm), ideal for various infrared and visible light applications.

- High Laser Damage Threshold: Suitable for laser applications, Zinc Sulfide can withstand high-intensity laser exposure.

- Light Yellow Translucency: Exhibits unique optical properties, appearing light yellow in visible light, making it suitable for specific optical systems.

Applications

- Infrared Thermal Imaging Systems: Ideal for use in the front-end optical components of thermal imaging systems, especially in harsh environmental conditions.

- Laser Systems: Due to its high laser damage threshold, Zinc Sulfide is used in laser system protective windows or other critical optical components.

- Optical Sensors: Commonly used in electronic sensors and environmental detectors as protective windows, isolating internal components from the external environment.

- High-Precision Optical Systems: Suitable for optical measurement and control systems that require high precision and stability.

- Visible and Infrared Sensor Systems: Widely used in visible and mid- to long-wave infrared sensor systems, providing efficient light transmission and protection.

| Physical Property | CVD Zinc Sulfide | Multispectral CVD Zinc Sulfide |

| Density | 4.09 g/cm³ | 4.09 g/cm³ |

| Resistivity | ~10¹² Ω·cm | ~10¹¹ Ω·cm |

| Melting Point | 1827 ℃ | - |

| Chemical Purity | 100.00% | 100.00% |

| Thermal Expansion | 6.6×10⁻⁶ @ 273K | 6.3×10⁻⁶ @ 273K |

| 7.3×10⁻⁶ @ 373K | 7.0×10⁻⁶ @ 373K | |

| Thermal Conductivity | 16.7 W/(m·K) @ 298K | 27.2 W/(m·K) @ 298K |

| Specific Heat Capacity | 0.469 J/(g·K) @ 298K | 0.515 J/(g·K) @ 298K |

| Knoop Hardness | 200-235 kg/mm² | 160 kg/mm² |

| Bending Strength | 103 MPa | - |

| Young's Modulus | 74.5 GPa | 74.5 GPa |

| Poisson's Coefficient | 0.29 | 0.29 |

| Optical Property | CVD Zinc Sulfide | Multispectral CVD Zinc Sulfide |

| Transmission Range | 1-14 μm | 0.37-14 μm |

| Refractive Index Inhomogeneity | <7.3×10⁻⁴ @ 10.6μm | <0.2×10⁻⁴ @ 632.8nm |

| Absorption Coefficient | 0.2 /cm @ 10.6μm | 0.2 /cm @ 10.6μm |

| Thermal Light Coefficient | 4.6×10⁻⁵ @ 1150nm | 5.43×10⁻⁵ @ 632.8nm |

| 4.3×10⁻⁵ @ 3390nm | 4.21×10⁻⁵ @ 1150nm | |

| 4.1×10⁻⁵ @ 10.6μm | 3.87×10⁻⁵ @ 3390nm |

| CVD Zinc Sulfide - Refractive Index and Wavelength | |||

| Wavelength (nm) | Refractive Index (n) | Wavelength (nm) | Refractive Index (n) |

| 620 | 2.355 | 9800 | 2.203 |

| 1000 | 2.292 | 10600 | 2.192 |

| 3800 | 2.253 | 11400 | 2.18 |

| 5000 | 2.246 | 12200 | 2.167 |

| 7000 | 2.232 | 13800 | 2.132 |

| 9000 | 2.212 | 14200 | 2.126 |

| Multispectral CVD Zinc Sulfide - Refractive Index and Wavelength | |||

| Wavelength (nm) | Refractive Index (n) | Wavelength (nm) | Refractive Index (n) |

| 400 | 2.545 | 8000 | 2.223 |

| 1010 | 2.292 | 9000 | 2.213 |

| 2060 | 2.264 | 10000 | 2.201 |

| 3500 | 2.255 | 11250 | 2.183 |

| 4500 | 2.25 | 12000 | 2.171 |

| 5000 | 2.247 | 13000 | 2.153 |

| Property | Value |

| Diameter Range | 2-300mm |

| Focal Length | 15-5000mm |

| Thickness | 0.12-60mm |

| Surface Quality | 80-50, 60-40, 40-20, 20-10, 10-5 |

| Surface Flatness | λ/2, λ/4, λ/8, λ/10 |

| Clear Aperture | >90% |

| Coating | Customizable |

new material

new material