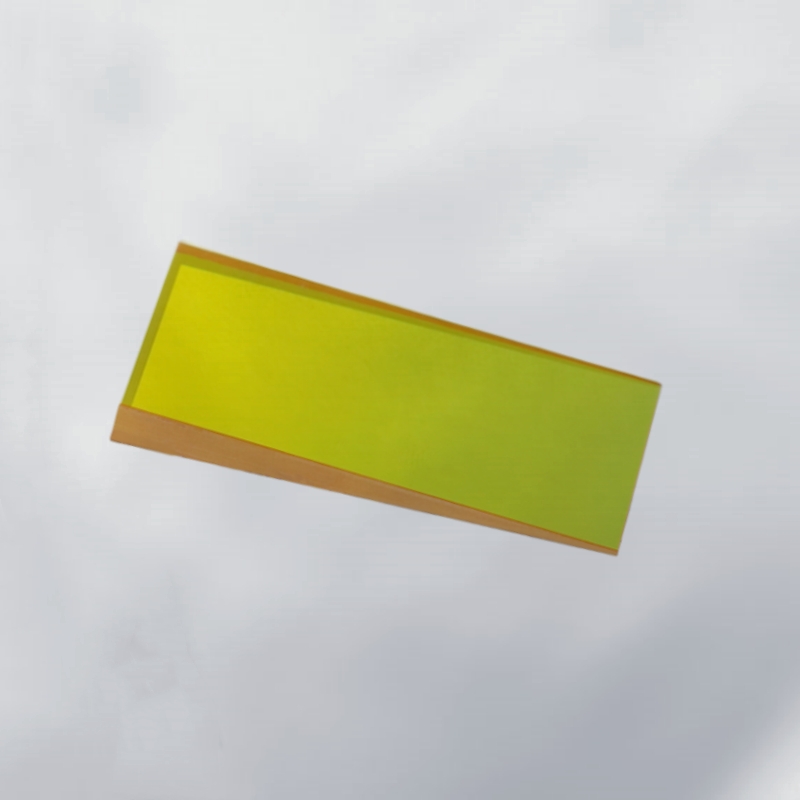

Zinc selenide wedge plates are high-performance optical components designed for superior infrared transmission, precise beam deviation control, and excellent chemical stability. Manufactured from high-purity ZnSe, these wedge-shaped plates provide outstanding optical clarity, low absorption, and durability, making them essential for laser optics, infrared imaging, aerospace applications, and precision scientific instruments. Their resistance to environmental degradation ensures reliable performance in advanced optical systems.

Product Overview

Zinc Selenide (ZnSe) wedge plates are specialized optical components with a wedge design, commonly used in optical systems as beam control elements. They are effective in eliminating interference patterns (such as fringe effects) caused by standard optics and preventing cavity feedback. ZnSe wedge plates are made through precision cutting, grinding, and polishing to ensure smooth surfaces and excellent optical performance. Additionally, they are typically coated to improve transmission and anti-reflection properties, optimizing their use in both visible and infrared bands.

Key Features

- High Transparency: ZnSe wedge plates provide excellent light transmission in both visible and infrared wavelengths, improving the optical system's efficiency.

- Low Reflectivity: Coating treatments provide low reflectivity, reducing light loss and improving overall system performance.

- High Thermal Stability: ZnSe offers excellent thermal stability, making it suitable for high-temperature environments.

- Strong Corrosion Resistance: Zinc selenide is highly resistant to corrosion, ensuring durability in various environmental conditions.

- Precision Manufacturing: These plates are produced using high-precision manufacturing processes to meet strict size and surface quality requirements, making them ideal for high-accuracy applications.

- Multi-band Transmission: ZnSe has good transmission capabilities across both visible light and infrared bands, making it suitable for a wide range of optical systems.

Applications

- LiDAR (Laser Detection and Ranging): Zinc selenide wedge plates are used in LiDAR systems as beam control elements, improving the stability and performance of the system.

- Optical Sensors: Commonly used in optical sensors to adjust and control light beams, enhancing the reliability of the system.

- Spectrometers: Used in spectrometers to control light paths, ensuring high-precision spectral analysis.

- Laser Systems: ZnSe wedge plates help prevent cavity feedback in laser systems, enhancing laser output stability.

- Telescopes: Used in the optical systems of telescopes to optimize light propagation and focusing, ensuring clear and stable images.

- Optical System Protection: As windows or lenses, ZnSe wedge plates protect optical systems from external contaminants and damage.

| Physical Property | Value |

| Crystal Structure | Cubic |

| Density | 5.27 g/cm³ |

| Resistivity | ~10¹² Ω·cm |

| Melting Point | 1525 ℃ |

| Chemical Purity | 100.00% |

| Thermal Expansion | 7.1×10⁻⁶ @ 273K |

| 7.8×10⁻⁶ @ 373K | |

| 8.3×10⁻⁸ @ 473K | |

| Thermal Conductivity | 18.0 W/(m·K) @ 298K |

| Specific Heat Capacity | 0.339 J/(g·K) @ 298K |

| Knoop Hardness | 110 kg/mm² |

| Bending Strength | 55 MPa |

| Young's Modulus | 67.2 GPa |

| Poisson's Coefficient | 0.28 |

| Optical Property | Value |

| Transmission Range | 0.5-22 μm |

| Refractive Index Inhomogeneity | <3×10⁻⁶ @ 632.8μm |

| Absorption Coefficient | 5.0×10⁻³ /cm @ 1300nm |

| 7.0×10⁻⁴ /cm @ 2700nm | |

| 4.0×10⁻⁴ /cm @ 3800nm | |

| 4.0×10⁻⁴ /cm @ 5250nm | |

| 5.0×10⁻⁴ /cm @ 10600nm | |

| Thermal Light Coefficient | 1.07×10⁻⁴ @ 632.8nm |

| 7.0×10⁻⁵ @ 1150nm | |

| 6.2×10⁻⁵ @ 3390nm | |

| 6.1×10⁻⁵ @ 10600μm | |

| Parameter | Range |

| Diameter Range | 2-300 mm |

| Thickness | 0.12-60 mm |

| Surface Finish | 80-50, 60-40, 40-20, 20-10, 10-5 |

| Surface Accuracy | λ/2, λ/4, λ/8, λ/10 |

| Parallelism | <3' - 30" |

| Aperture Transmission | >90% |

| Coating | Customizable |

new material

new material