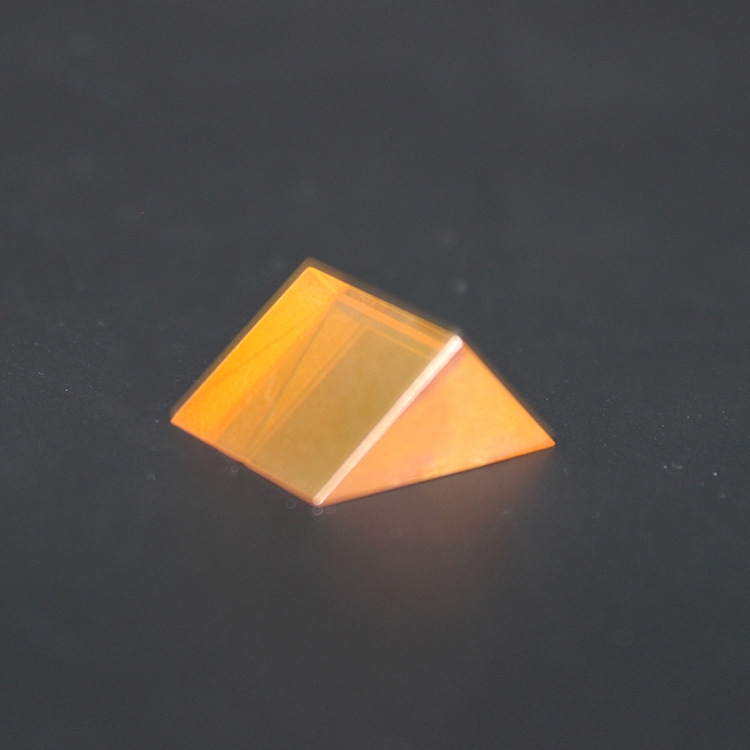

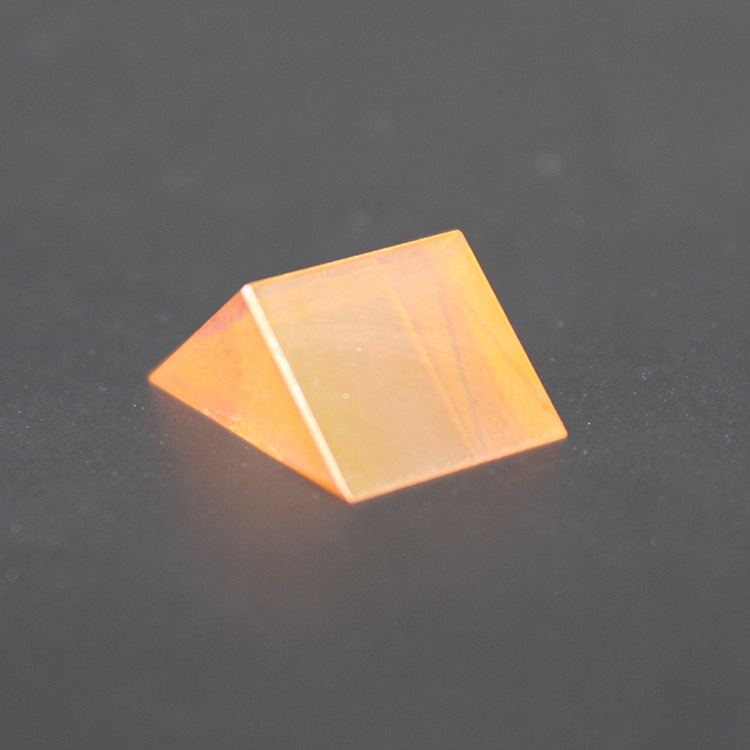

Zinc selenide right-angle prism is a high-performance optical component designed for superior infrared transmission, exceptional chemical stability, and minimal absorption. Manufactured from high-purity ZnSe, it offers outstanding optical clarity, precise light redirection, and excellent mechanical durability. This prism is widely used in infrared imaging systems, laser optics, aerospace applications, and precision scientific instruments, ensuring accurate beam manipulation and reflection in advanced optical assemblies.

Product Overview

The Zinc Selenide (ZnSe) right-angle prism is an optical element made from high-quality ZnSe material, widely used for optical path deflection and image deviation. This prism can deflect the image formed in an optical system by 90°, making it ideal for beam displacement, image combining, and other applications requiring precise control of optical paths. ZnSe, as an excellent optical material, offers good transmission and low absorption across a wavelength range of 600 nm to 16 µm, ensuring high performance across ultraviolet, visible, and infrared spectra.

The prism also features excellent thermal shock resistance and high stability, maintaining stable optical performance even in high-temperature environments. Its unique 45° and 90° angular design makes installation more convenient, while providing strong mechanical stress resistance.

Key Features

- High Light Transmission: Zinc Selenide material offers excellent transmission in the ultraviolet, visible, and infrared spectra.

- Low Absorption: Features low optical absorption, ensuring efficient light transmission.

- Thermal Shock Resistance: Exhibits excellent thermal shock resistance, making it suitable for harsh applications in high-temperature environments.

- Stability and Strength: The large contact area and superior mechanical stability enable it to withstand significant mechanical stress.

- Optical Coating: Often coated with optical films to improve transmission and reduce reflection losses.

Applications

- Optical Path Deflection and Deviation: Used for deflecting the optical path or image by 90°, widely used in laser systems.

- Laser Alignment: Particularly suitable for optical path adjustments in systems like CO2 lasers.

- Beam Displacement: Used for precise beam displacement in laser processing, beam synthesis, and beam steering applications.

- Infrared Applications: Due to its excellent transmission in the infrared range, it is well-suited for infrared imaging systems and other high-precision optical devices.

| Physical Property | Value |

| Crystal Structure | Cubic |

| Density | 5.27 g/cm³ |

| Resistivity | ~10¹² Ω·cm |

| Melting Point | 1525 ℃ |

| Chemical Purity | 100.00% |

| Thermal Expansion | 7.1×10⁻⁶ @ 273K |

| 7.8×10⁻⁶ @ 373K | |

| 8.3×10⁻⁸ @ 473K | |

| Thermal Conductivity | 18.0 W/(m·K) @ 298K |

| Specific Heat Capacity | 0.339 J/(g·K) @ 298K |

| Knoop Hardness | 110 kg/mm² |

| Bending Strength | 55 MPa |

| Young's Modulus | 67.2 GPa |

| Poisson's Coefficient | 0.28 |

| Optical Property | Value |

| Transmission Range | 0.5-22 μm |

| Refractive Index Inhomogeneity | <3×10⁻⁶ @ 632.8μm |

| Absorption Coefficient | 5.0×10⁻³ /cm @ 1300nm |

| 7.0×10⁻⁴ /cm @ 2700nm | |

| 4.0×10⁻⁴ /cm @ 3800nm | |

| 4.0×10⁻⁴ /cm @ 5250nm | |

| 5.0×10⁻⁴ /cm @ 10600nm | |

| Thermal Light Coefficient | 1.07×10⁻⁴ @ 632.8nm |

| 7.0×10⁻⁵ @ 1150nm | |

| 6.2×10⁻⁵ @ 3390nm | |

| 6.1×10⁻⁵ @ 10600μm | |

| Item | Value |

| Available Size | 2-100mm |

| Precision | 20-10, 1/10L@633nm |

| Product Type | Right-angle prisms |

| Processes | Glue disc polishing, High-speed polishing, Annular polishing, CNC polishing |

| Measuring Equipment | ZYGO, AFM, Reflection and transmission eccentricity instruments, 15-second angle meter, UV bonding centering system, Non-contact laser thickness gauge, 2D imaging system, Spherometer |

| Data Accuracy | Ensured accuracy |

new material

new material