Product Overview

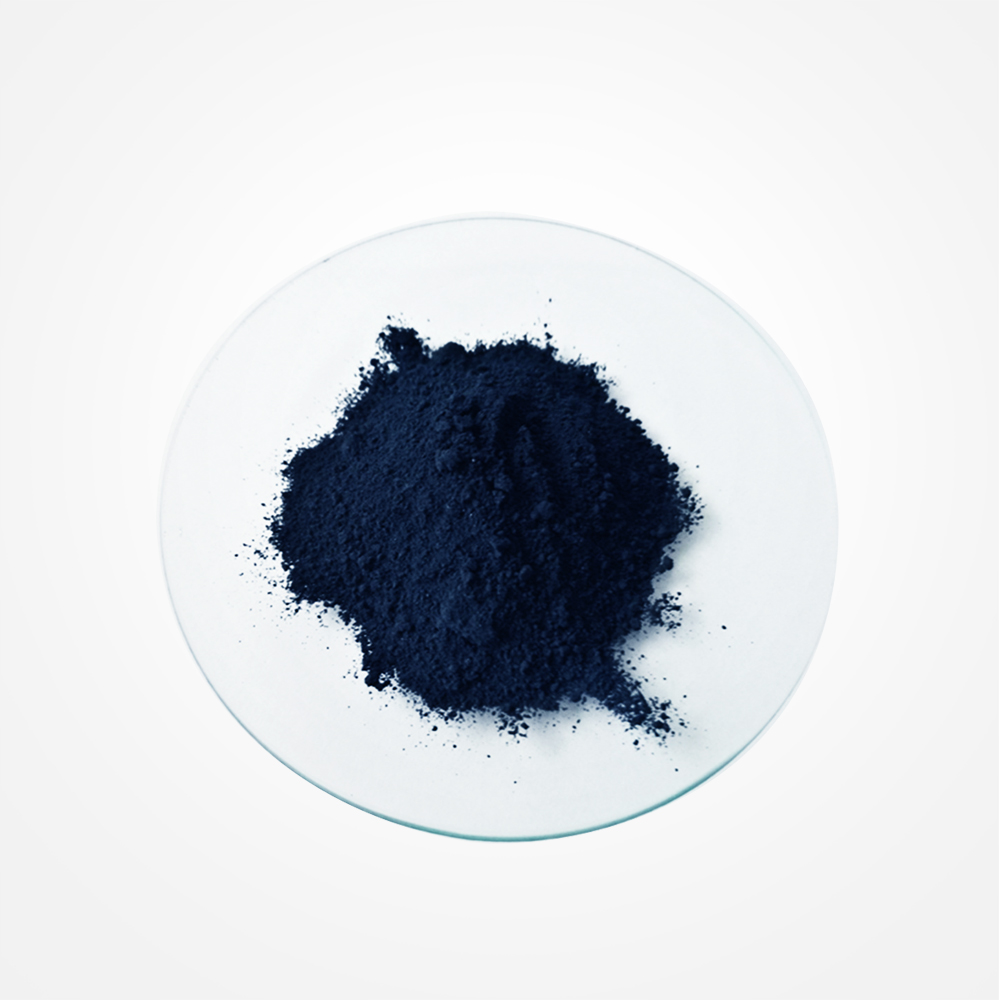

Hafnium powder is a silver-gray metallic powder with a lustrous appearance. It is highly corrosion-resistant and exhibits excellent stability at high temperatures. Hafnium readily reacts with gases such as oxygen and nitrogen to form oxides and nitrides. Its significant thermal neutron capture cross-section makes it an indispensable material for the nuclear industry. Additionally, hafnium is widely used in electronics, aerospace, and high-temperature alloy manufacturing.

Features

- High Purity and Stability:Suitable for precision industrial applications.

- Exceptional Corrosion Resistance and Heat Stability:Ideal for demanding environments.

- Thermal Neutron Capture Efficiency:Optimized for nuclear applications.

- Versatile Processing:Customizable to meet various specification requirements.

Applications

- Nuclear Industry:Used in control rods and shielding devices for nuclear reactors, leveraging its high neutron absorption efficiency.

- Electronics Industry:Serves as a cathode material for X-ray tubes and enhances transistor density while reducing power consumption in semiconductor manufacturing.

- Aerospace Applications:Applied in rocket nozzles and protective coatings for high-temperature components, ensuring durability in extreme conditions.

- Alloy Manufacturing:Additive for refractory alloys such as tungsten, molybdenum, and tantalum, increasing material strength and hardness.

- Hard Alloys:Incorporated into hard alloys like hafnium carbide (HfC), prized for its high hardness and melting point.

- Getter Material:Removes residual gases in vacuum systems, ensuring a higher level of system purity.

- Industrial Hydraulic Oils:Enhances anti-evaporation properties in hydraulic oils, suitable for hazardous environments.

- Semiconductor Technology:Used as a high-K dielectric material in advanced transistor production, reducing leakage and improving device performance.

| Specification | ||||||

| Content | Hf+Zr | Zr | Fe | Mg | Ni | Cl |

| ≥99.9% | ≤2.0% | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.5% | |

| Particle Size | -200 mesh, -400 mesh, 325mesh, 1-3um | |||||

new material

new material