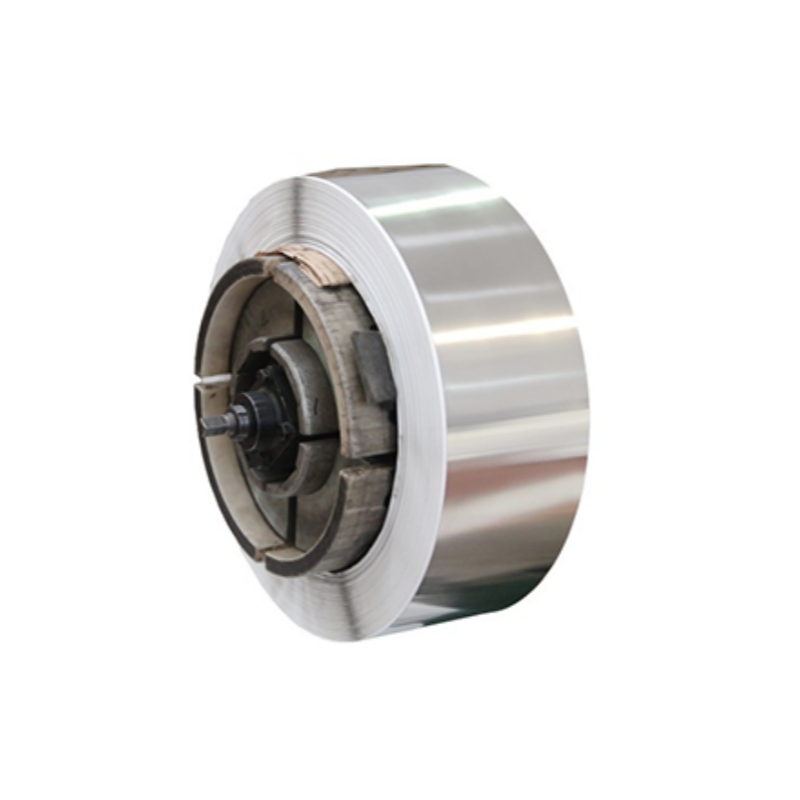

GH1140 High-Temperature Alloy is a nickel-based superalloy widely used in aerospace, power generation, and high-temperature industrial applications. Known for its excellent oxidation resistance, superior mechanical strength, and high-temperature stability, this alloy is ideal for turbine components, combustion chambers, and other critical parts subjected to extreme thermal conditions.

Product Overview

GH1140 is a solid-solution strengthened high-temperature alloy based on Fe-Ni, primarily used in aerospace engine parts, gas turbine combustion chamber components, and turbine engine combustion chamber parts. This alloy has moderate thermal strength and high plasticity, making it stable for high-temperature applications. It is particularly suitable for environments subject to thermal fatigue, thermal shock, and high-load conditions at elevated temperatures. GH1140 also offers good weldability, meeting the demands of complex structural component processing.

Key Features

- Excellent Thermal Fatigue Resistance: Provides excellent thermal fatigue resistance in high-temperature environments, making it ideal for high-load applications.

- Stable Microstructure: The alloy has good microstructural stability, ensuring that its properties do not degrade under prolonged high-temperature use.

- Good Weldability: GH1140 offers excellent welding performance, facilitating easier processing and maintenance of components.

- Moderate Thermal Strength and High Plasticity: Well-suited for medium to high-temperature environments while maintaining good plasticity and thermal strength.

Applications

- Aerospace Engines: Used to manufacture high-temperature components such as turbine discs, combustion chamber structural parts, and more.

- Gas Turbines: Widely used for combustion chamber components and related structural parts in gas turbines.

- Turbine Engines: Suitable for key parts of turbine engines, particularly those that must withstand high temperatures and heavy loads.

- High-Temperature Environments: Ideal for manufacturing structural components and parts that operate in high-temperature, complex environments.

| C | Cr | Ni | W | Mo | Al | Ti | |||||

| 0.06~0.12 | 20.0~23.0 | 35.0~40.0 | 1.40~1.80 | 2.00~ | 0.20~0.60 | 0.70~1.20 | |||||

| 2.5 | |||||||||||

| Fe | Ce | Mn | Si | P | S | ||||||

| Balance | ≤0.05 | ≤0.7 | ≤0.8 | ≤0.025 | ≤0.015 | ||||||

| Specification | Room Temp. | 800℃ | ||||

| ᵟb /MPa | ᵟ5 /% | Φ/% | ᵟb /Mpa | ᵟ5 /% | Φ/% | |

| Rod | 620 | 40 | 45 | 245 | 40 | 50 |

| Hot Rolled Plate | 635 | 40 | 50 | 245 | 40 | 50 |

| Cold Rolled Plate | 635 | 40 | 225 | 40 | 50 | |

| Pipe | 590 | 35 | ||||

new material

new material