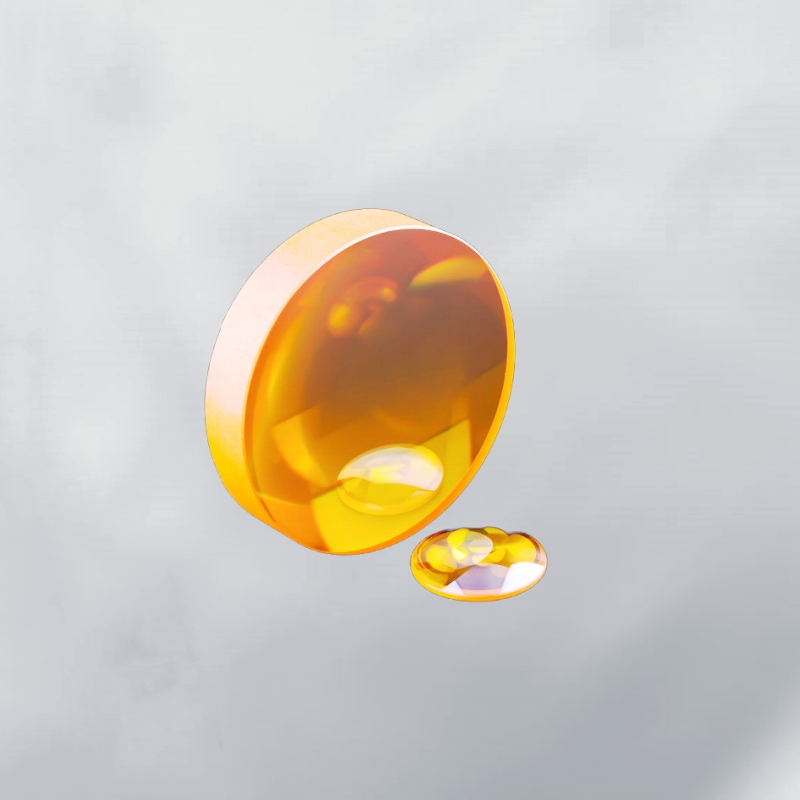

Zinc selenide double-convex lens is a high-performance optical component designed for efficient light convergence, minimized spherical aberration, and superior infrared transmission. Manufactured from high-purity ZnSe, it offers exceptional optical clarity, strong resistance to environmental fluctuations, and reliable thermal stability. This precision lens is widely used in infrared imaging, laser optics, aerospace applications, and scientific instrumentation, ensuring optimal light manipulation and performance for advanced optical systems.

Product Overview

The Zinc Selenide (ZnSe) double-convex lens is an optical lens made from high-purity Zinc Selenide material. It features two spherical convex surfaces with equal curvature radii, designed to focus light to a single point. ZnSe exhibits exceptional optical properties in the infrared spectrum, making it a popular choice for thermal imaging systems and some visible light optical systems. With characteristics such as low optical absorption and excellent thermal shock resistance, this lens excels in high-power applications.

Key Features

- High Transmission Efficiency: Suitable for multiple spectral bands, especially offering high transmission in the infrared spectrum.

- Low Absorption & Thermal Shock Resistance: ZnSe has low optical absorption and superior thermal shock resistance, making it ideal for high-power laser and thermal imaging applications.

- Precision Manufacturing: Manufactured using advanced processing and polishing techniques, ensuring high surface quality and dimensional accuracy.

- Coating Options: Can be coated with anti-reflective coatings to improve performance and optical transmission.

- High Hardness: ZnSe material has a relatively high hardness, eliminating the need for additional protective coatings, making it suitable for high-power applications.

Applications

- Thermal Imaging Systems: Widely used in infrared imaging and thermal imaging devices, providing high-quality image transmission.

- Laser Systems: Used in laser systems for beam focusing and imaging, enhancing optical performance.

- Optical Instruments & Spectral Analysis: Suitable for various optical instruments and spectroscopic systems, providing precise imaging.

- High-Power Applications: Due to its high hardness and low absorption, it is ideal for high-power laser systems and environments that require advanced performance.

| Physical Property | Value |

| Crystal Structure | Cubic |

| Density | 5.27 g/cm³ |

| Resistivity | ~10¹² Ω·cm |

| Melting Point | 1525 ℃ |

| Chemical Purity | 100.00% |

| Thermal Expansion | 7.1×10⁻⁶ @ 273K |

| 7.8×10⁻⁶ @ 373K | |

| 8.3×10⁻⁸ @ 473K | |

| Thermal Conductivity | 18.0 W/(m·K) @ 298K |

| Specific Heat Capacity | 0.339 J/(g·K) @ 298K |

| Knoop Hardness | 110 kg/mm² |

| Bending Strength | 55 MPa |

| Young's Modulus | 67.2 GPa |

| Poisson's Coefficient | 0.28 |

| Optical Property | Value |

| Transmission Range | 0.5-22 μm |

| Refractive Index Inhomogeneity | <3×10⁻⁶ @ 632.8μm |

| Absorption Coefficient | 5.0×10⁻³ /cm @ 1300nm |

| 7.0×10⁻⁴ /cm @ 2700nm | |

| 4.0×10⁻⁴ /cm @ 3800nm | |

| 4.0×10⁻⁴ /cm @ 5250nm | |

| 5.0×10⁻⁴ /cm @ 10600nm | |

| Thermal Light Coefficient | 1.07×10⁻⁴ @ 632.8nm |

| 7.0×10⁻⁵ @ 1150nm | |

| 6.2×10⁻⁵ @ 3390nm | |

| 6.1×10⁻⁵ @ 10600μm | |

| Property | Value |

| Diameter Range | 2-300mm |

| Focal Length | 15-5000mm |

| Thickness | 0.12-60mm |

| Surface Quality | 80-50, 60-40, 40-20, 20-10, 10-5 |

| Surface Flatness | λ/2, λ/4, λ/8, λ/10 |

| Clear Aperture | >90% |

| Coating | Customizable |

new material

new material