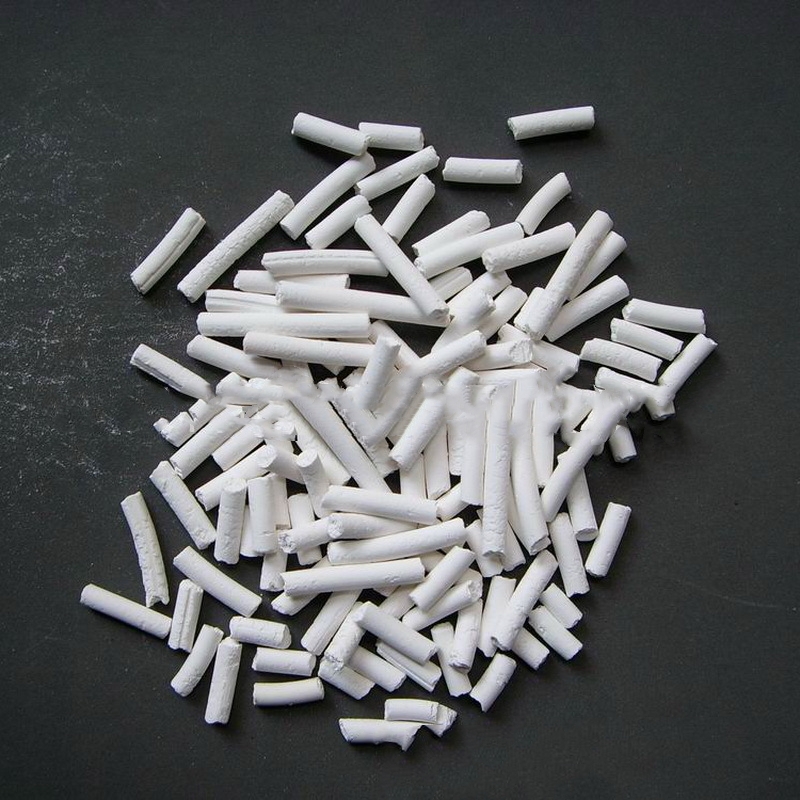

Aromatization catalyst is a high-performance catalytic material designed to facilitate the selective conversion of alkanes into aromatic hydrocarbons with superior efficiency. Engineered using advanced zeolite-based or metal-supported catalysts, it ensures optimized reaction kinetics, enhanced yield, and prolonged operational stability in petrochemical refining processes. This catalyst is widely used in gasoline upgrading, aromatic compound synthesis, and industrial hydrocarbon transformation, providing reliable performance for large-scale applications requiring precision catalytic control.

Product Overview:

The aromatization catalyst is widely used in the aromatization reactions of C3 and C4 gases, straight-run gasoline, condensates, and other feedstocks. This catalyst effectively converts C5 fractions into valuable aromatics such as benzene (B), toluene (T), and xylene (X), while also producing valuable by-products like ethylene, propylene, ethane, and propane. The catalyst offers high conversion rates and excellent aromatic yield, making it particularly suitable for feedstocks with high olefin content. It efficiently transforms light hydrocarbon feedstocks into high-value-added products.

Key Features:

- Broad Feedstock Adaptability:Suitable for various feedstocks, including C3-C7 light hydrocarbons, straight-run gasoline, and condensates.

- High Conversion Rate:Ensures high efficiency in catalytic reactions, maximizing the yield of aromatics.

- Strong Coke Resistance:Especially effective for feedstocks with high olefin content (such as C5), with excellent coke resistance that extends catalyst life.

- High Aromatic Yield:Efficiently produces benzene, toluene, xylene, and other aromatic compounds with high selectivity.

- Valuable By-product Production:In addition to aromatics, the catalyst produces valuable by-products such as ethylene, propylene, and other high-value chemicals, enhancing economic returns.

Applications:

- Aromatization Reactions:Widely used in the aromatization of C3-C7 light hydrocarbons, straight-run gasoline, and condensates to increase aromatic content.

- High-Octane Gasoline Production:Particularly important in the petroleum refining industry for producing high-octane gasoline.

- Light Hydrocarbon Conversion:Used for the aromatization of by-products from ethylene production (C3-C7), transforming them into high-value aromatics and other chemicals.

| Operating Conditions | |

| Item | Parameter |

| Space Velocity | 0.6~1.0 h⁻¹ (W/W) |

| Reaction Temperature | 450~570℃ |

| Reaction Pressure | Atmospheric Pressure (NPT) |

| Conversion of C5 | >95% |

| Product Composition | 70% Liquid; 30% Gas |

| One-way Catalyst Life | Alkanes >200h; Olefins >24h |

| Regeneration Cycle | <20h |

| Total Life | >8 months |

| Liquid Composition | |

| Product | Content (%) |

| C5 | 1.8 |

| Benzene | 22.4 |

| Toluene | 45.79 |

| Xylene | 25.23 |

| Others | 4.8 |

| Gas Composition | |

| Product | Content (%) |

| Methane | 13.12 |

| Ethane | 17.96 |

| Ethylene | 7.7 |

| Propane | 41.45 |

| Propylene | 6.85 |

| C4 | 13.56 |

new material

new material