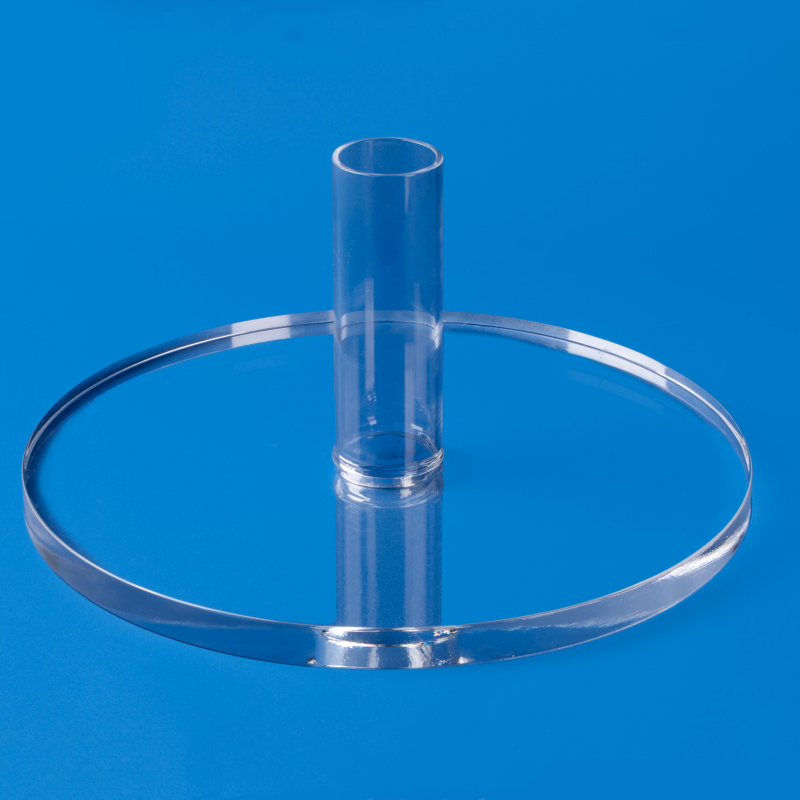

Annealing quartz door is a high-purity quartz component designed for superior thermal resistance, excellent chemical stability, and precise dimensional accuracy. Manufactured using advanced fusion techniques, it ensures minimal thermal expansion, optimal durability, and high transparency for specialized applications. This material is widely used in semiconductor fabrication, laboratory research, vacuum systems, and industrial annealing processes, providing reliable performance in high-temperature environments requiring controlled thermal treatment.

Product Overview

The Annealing Quartz Door is made from high-purity quartz, specifically designed for the high-temperature annealing processes in the photovoltaic (PV) industry. It offers exceptional resistance to high temperatures and chemical stability, allowing it to operate reliably in high-temperature, low-oxygen environments. The transparent nature of the quartz door provides clear visibility of the temperature distribution and status of the workpieces inside the furnace, making it an essential component in the heat treatment and annealing processes for solar cell production.

Key Features

- High-Purity Quartz: Made from high-purity quartz to ensure that no impurities are released during high-temperature processes, preventing contamination in photovoltaic products.

- High-Temperature Resistance: Can withstand temperatures over 1000°C, making it suitable for high-temperature annealing processes in the photovoltaic industry.

- Chemical Stability: Excellent resistance to corrosion, allowing the door to operate in various harsh chemical environments.

- Good Transparency: High light transmittance, enabling operators to monitor and control the furnace process effectively.

- Strong Thermal Stability: Low thermal expansion coefficient, reducing the impact of temperature fluctuations on the equipment, thus extending its service life.

Applications

- Photovoltaic Industry: Widely used in the high-temperature annealing and heat treatment processes for solar cell production, ensuring process stability.

- Solar Cell Manufacturing: Used in the annealing furnaces for solar cell production, ensuring smooth operation during high-temperature processes.

- High-Temperature Equipment: Ideal for various industrial furnaces and heating equipment that require high-temperature and chemical corrosion resistance.

- Heat Treatment Processes: Applied in heat treatment processes for metals and materials, where high-temperature and precise process control are required.

new material

new material