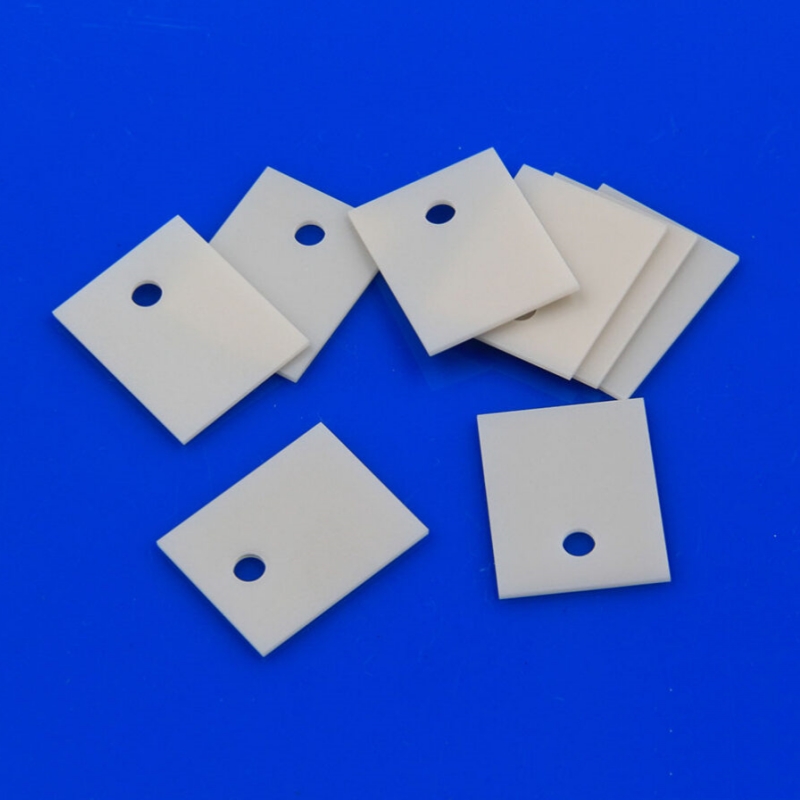

Aluminum nitride heat sinks, also known as high thermal conductivity ceramic cooling plates, are advanced thermal management components designed for applications requiring efficient heat dissipation, excellent electrical insulation, and superior mechanical durability. Manufactured through precision sintering and machining, these ceramic heat sinks provide exceptional thermal conductivity, low thermal expansion, and high resistance to oxidation. They are widely used in semiconductor processing, power electronics, aerospace systems, high-performance LED modules, and industrial cooling applications, ensuring long-term efficiency in demanding environments.

Product Overview

Aluminum Nitride (AlN) Heat Sinks, also known as high thermal conductivity ceramic cooling plates, are designed specifically for efficient heat dissipation. Made from high-quality AlN ceramic material, these heat sinks excel in rapidly transferring heat from the heat source and efficiently dissipating it through their large surface area. This enhances the operational efficiency and stability of the equipment. They are particularly ideal for applications where thermal management is critical, such as high-performance computing, power semiconductors, and LED lighting.

Features

- High Thermal Conductivity: With a thermal conductivity of up to 170 W/m·K, AlN heat sinks rapidly absorb and conduct heat, ensuring effective cooling and optimizing temperature control for devices.

- Excellent Electrical Insulation: AlN heat sinks feature a breakdown strength of 17-19 KV/mm and low dielectric loss, providing efficient thermal management while maintaining electrical insulation properties.

- Low Thermal Expansion Coefficient: The thermal expansion coefficient ranges from 3.2-3.4×10<sup>-6</sup>/ºC, which is close to that of silicon materials, reducing mechanical stress due to thermal expansion mismatches.

- Good Thermal Stability: AlN heat sinks can operate in environments as high as 1000°C with excellent thermal shock resistance, making them ideal for high-temperature operating conditions.

- Smooth Surface & Uniform Thickness: The smooth surface and uniform thickness improve thermal contact efficiency, reducing thermal resistance and further enhancing heat dissipation performance.

Applications

Aluminum Nitride heat sinks play a crucial role in many high-tech industries, particularly in the following applications:

- High-Performance Computing: Used in servers and workstations that generate significant heat, AlN heat sinks provide efficient cooling, ensuring stable and efficient operation.

- Power Semiconductors & Power Electronics: Used in inverters, electric vehicle drive systems, and other power electronic components, AlN heat sinks effectively manage the heat generated by power devices, ensuring optimal heat dissipation.

- LED Lighting: Due to the high heat generated by LED components, AlN heat sinks extend the lifespan of LEDs and maintain their light efficiency.

- Electronics Packaging: AlN heat sinks are widely used in semiconductor packaging to reduce heat buildup within the package, improving overall device performance and reliability.

new material

new material