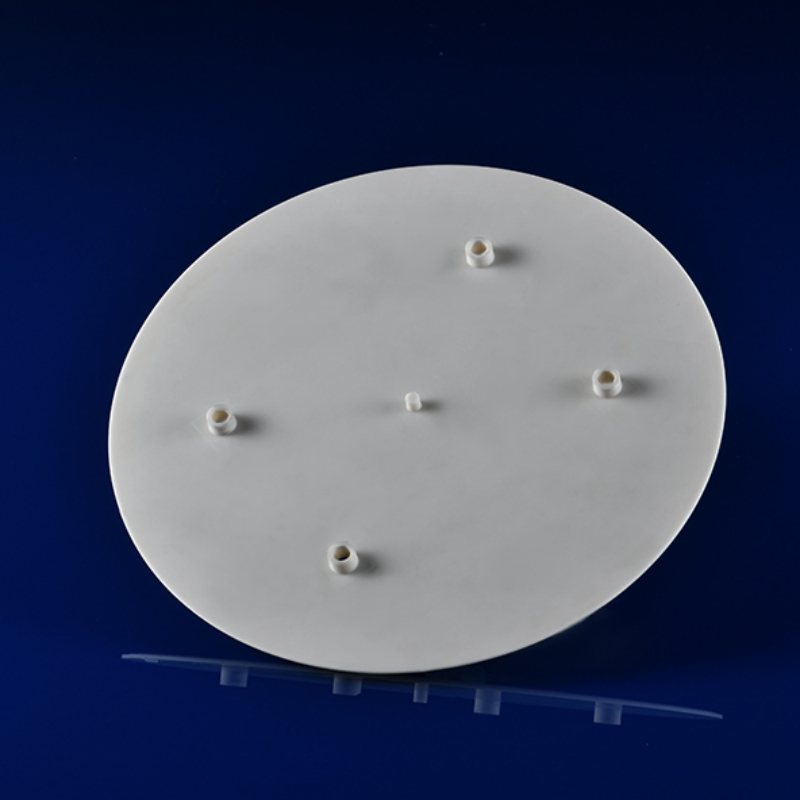

Aluminum nitride ceramic wafer carriers (AlN wafer carriers) are high-performance thermal management components designed for precision wafer handling in semiconductor processing. Manufactured using advanced sintering and machining techniques, these ceramic carriers provide superior thermal conductivity, exceptional electrical insulation, and outstanding mechanical durability. They ensure high stability, minimal thermal expansion, and long-term reliability in demanding environments, making them essential for high-precision semiconductor manufacturing and high-temperature applications.

Product Overview

The Aluminum Nitride Ceramic Wafer Carrier plays a crucial role in semiconductor manufacturing, primarily used for supporting and transporting wafers. Made from high-purity AlN material, it offers excellent thermal conductivity and electrical insulation, maintaining stability even in high-temperature environments. JunJie Ceramics offers custom services, allowing for the production of wafer carriers in various sizes and specifications to meet the stringent requirements of industrial applications.

Features

- Excellent Thermal Conductivity: AlNceramics have extremely high thermal conductivity, enabling rapid heat dissipation and preventing uneven heating that could affect wafer quality.

- Electrical Insulation: Good electrical insulating properties ensure stability and safety in electrical environments.

- High-Temperature Stability: AlNmaterial remains stable across a wide temperature range, making it ideal for use in high-temperature semiconductor processing.

- Customization: We offer custom services to manufacture wafer carriers in various sizes and specifications, tailored to meet specific semiconductor production needs.

- Precision Machining: Our fine machining capabilities ensure that each wafer carrier meets strict dimensional and tolerance requirements for high-precision applications.

Applications

The AlN Wafer Carrier is essential in several critical industries, especially semiconductor manufacturing:

- Semiconductor Industry: Used during the wafer manufacturing, storage, and transport processes as a support and protection material for wafers.

- Electronics Manufacturing: In high-precision electronic component production, wafer carriers help during wafer processing, testing, and transport.

- High-Temperature Environments: Suitable for use in high-temperature, precision equipment that requires both excellent thermal conductivity and electrical insulation.

new material

new material