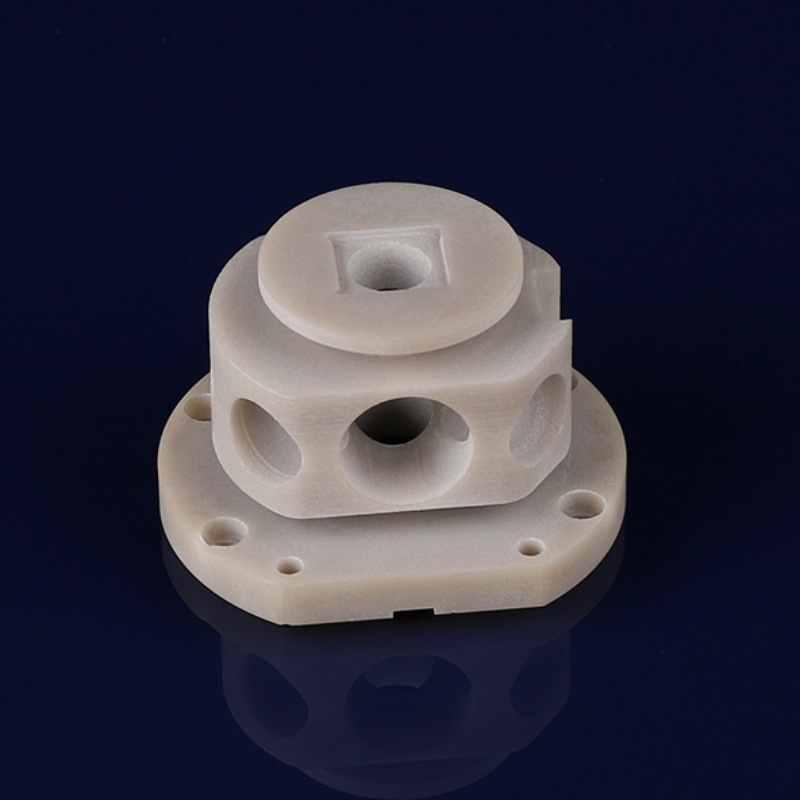

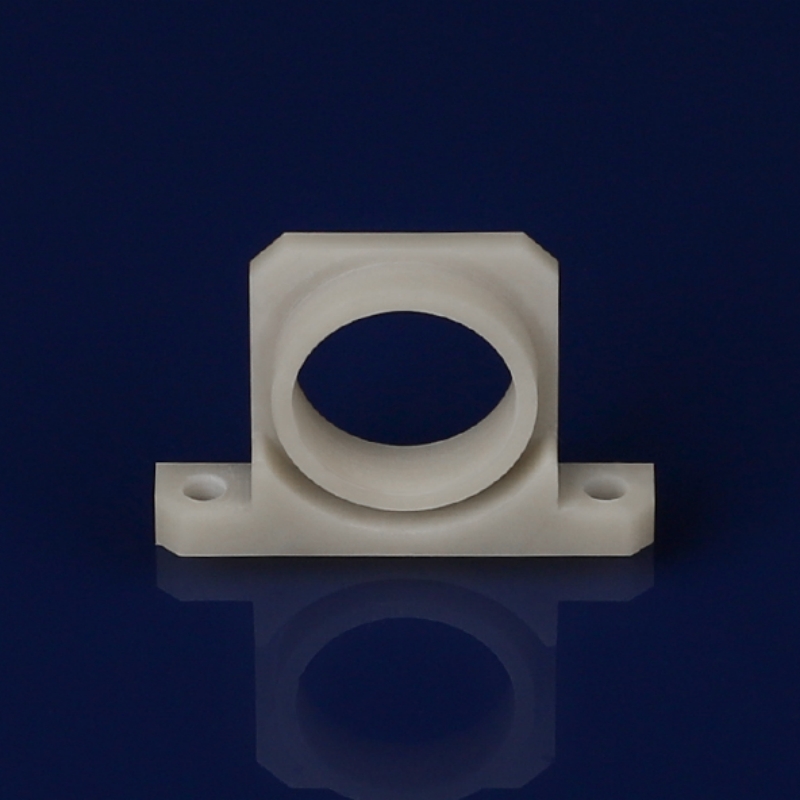

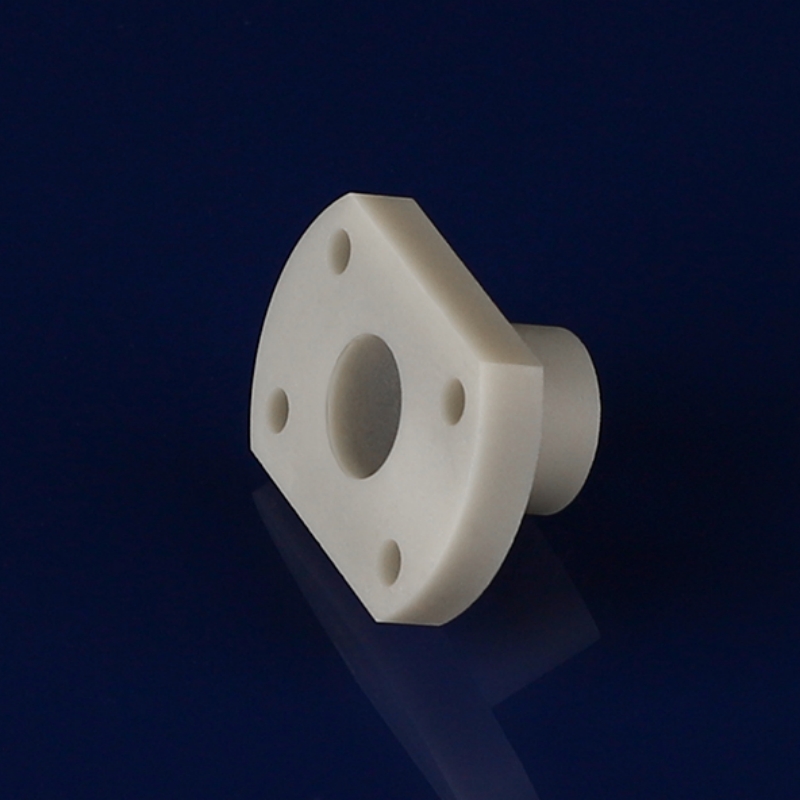

Aluminum nitride ceramic structural parts are advanced engineering components designed for applications requiring superior thermal conductivity, excellent electrical insulation, and outstanding mechanical durability. Manufactured through precision sintering and machining techniques, these ceramic components exhibit exceptional thermal stability, low thermal expansion, and high resistance to oxidation and wear. They are widely used in semiconductor processing, aerospace engineering, high-frequency electronic devices, power electronics, and high-performance industrial applications where efficient thermal management and structural integrity are critical.

Product Overview

Aluminum Nitride (AlN) ceramic is a high-performance material characterized by excellent thermal conductivity, low thermal expansion coefficient, and good electrical insulation and thermal stability. With thermal conductivity superior to traditional ceramics like alumina (Al2O3) and beryllia (BeO), AlN ceramic is widely used in thermal management systems for high-frequency and high-power electronic devices. Additionally, its high mechanical strength, thermal shock resistance, and outstanding chemical corrosion resistance make it an ideal choice for numerous high-tech applications.

Features

- High Thermal Conductivity: Theoretical thermal conductivity can reach 320 W/(m·K), with practical values ranging from 100 to 250 W/(m·K), greatly improving heat management efficiency in various applications.

- Electrical Insulation: Excellent electrical insulation properties make AlN ceramic ideal for electrical insulation applications in high-power devices.

- Low Thermal Expansion: With a thermal expansion coefficient close to that of silicon, it is well-suited for use with silicon materials, helping reduce thermal stress in devices.

- High Chemical Resistance: Resistant to a wide range of chemical corrosion, AlN ceramic is ideal for use in harsh environments.

- Excellent Thermal Stability: Capable of maintaining stable performance even in high-temperature environments, making it suitable for high-temperature applications.

Applications

Aluminum Nitride ceramic structural parts play an essential role in a variety of high-tech industries, especially in applications where high thermal conductivity, low thermal expansion, and mechanical strength are critical:

- Electronics Industry: Used in semiconductor packaging, thermal management, and high-frequency applications to ensure optimal performance and reliability.

- Medical Industry: Serves as a thermal exchange material in medical devices, ensuring the stable operation of electronic components under high-temperature conditions.

- Semiconductor Industry: Used in heat sinks, microwave terminals, and resistors for high-power semiconductor devices and other high-frequency applications.

- Energy and Metallurgical Sectors: Used in high-temperature applications such as metal melting and crystal growth crucibles, offering excellent thermal stability and durability.

- Telecommunications and Laser Industries: Applied as RF/microwave window materials, thermocouple insulators, and other precision components in communication and laser systems.

new material

new material