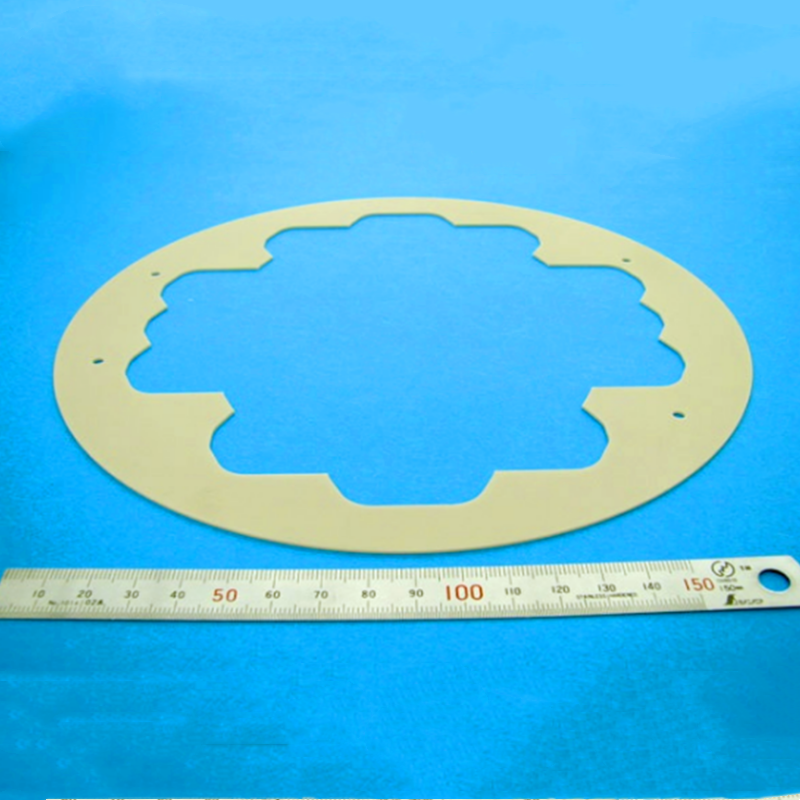

Aluminum Nitride Ceramic Pressure Ring (AlN Ceramic Pressure Ring) is a high-performance ceramic component designed for applications requiring exceptional thermal conductivity, electrical insulation, and mechanical strength under high-pressure conditions. Made from premium-grade Aluminum Nitride (AlN), this pressure ring offers excellent resistance to thermal shock, corrosion, and wear, making it ideal for semiconductor processing, LED manufacturing, power electronics, and other demanding industrial applications. Its precise dimensions and durability ensure reliable performance in extreme environments.

Product Overview

The Aluminum Nitride Ceramic Pressure Ring is a high-performance component designed primarily for the semiconductor industry, made from high-purity AlN material. It is renowned for its exceptional thermal conductivity and electrical insulation properties. Due to the high hardness and outstanding chemical stability of aluminum nitride, precision machining is required during the manufacturing process. This pressure ring is widely used in the packaging and heat management systems of semiconductor devices, ensuring reliable performance under high-temperature and high-pressure conditions.

Features

- Superior Thermal Conductivity: Provides excellent heat management, ensuring the stable operation of electronic components and preventing overheating.

- High Electrical Insulation: With a low dielectric constant and minimal dielectric loss, it ensures electrical safety in sensitive environments.

- High Hardness: The material's high hardness makes it ideal for harsh working environments but also demands high-precision manufacturing techniques.

- Low Thermal Expansion Coefficient: Matches the thermal expansion coefficient of silicon, preventing material stress due to temperature fluctuations.

- Chemical Stability: Exceptional resistance to corrosion and chemical degradation, making it suitable for demanding environments and applications.

Applications

- Semiconductor Industry: Used in semiconductor packaging and heat dissipation systems, helping to lower device operating temperatures and extend lifespan.

- Electronic Devices: Acts as a heat dissipation accessory in high-power electronic equipment, ensuring stable operation of sensitive components.

- High-Temperature Environments: Ideal for high-end industrial applications that require materials resistant to high temperatures and corrosion, such as lasersand laser equipment.

new material

new material