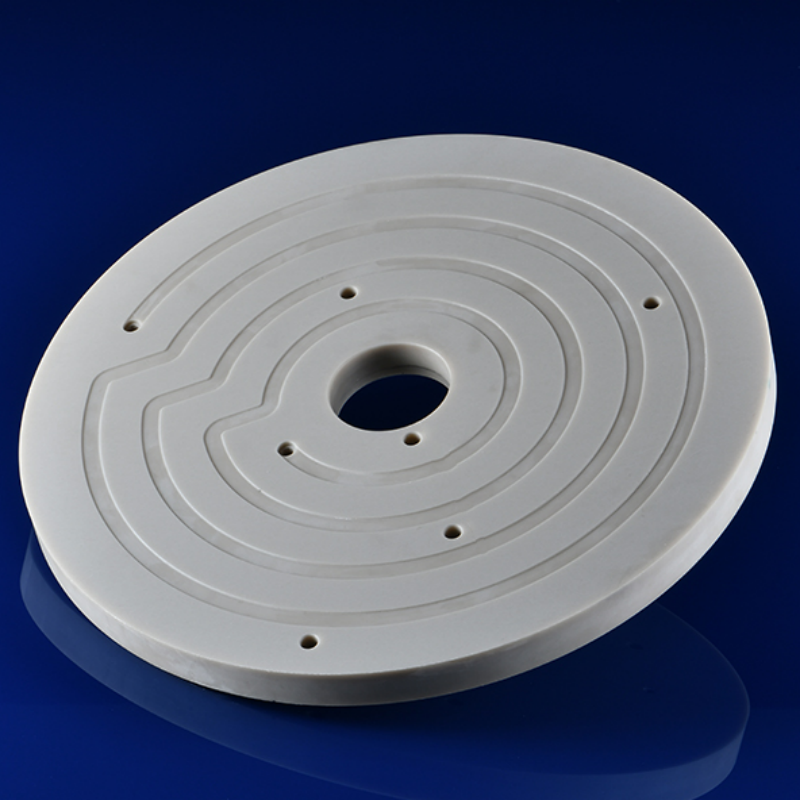

Aluminum nitride ceramic heater plates (AlN heaters) are high-performance thermal management components designed for applications requiring efficient heat generation, exceptional thermal conductivity, and superior electrical insulation. Manufactured through precision sintering and machining techniques, these ceramic heater plates provide high power density, uniform heating distribution, and strong resistance to oxidation. They are widely used in semiconductor processing, aerospace systems, medical devices, industrial heating applications, and electronic equipment where reliable thermal performance is critical.

Product Overview

The Aluminum Nitride Ceramic Heater Plate is made from high-purity AlN material, offering exceptional thermal conductivity, electrical insulation, and thermal stability. This heater plate is ideal for high-power electronic devices requiring efficient heat dissipation. It can be customized with fine drilling, grinding, and threading to meet strict tolerances and specifications, making it suitable for a variety of high-performance applications.

Features

- High Thermal Conductivity: AlN material has excellent thermal conductivity, rapidly and effectively transferring heat away from electronic components to ensure stable performance.

- Electrical Insulation: The heater plate also provides good electrical insulation, making it suitable for high-power electronic components that require electrical isolation.

- Low Thermal Expansion Coefficient: With a thermal expansion coefficient similar to silicon, it remains highly stable under large temperature fluctuations, making it particularly suitable for the semiconductor industry.

- High Temperature Stability: Maintains stability over a wide temperature range, unaffected by temperature fluctuations.

- Customizable: We offer customization services, enabling the production of heater plates in various sizes and shapes according to customer needs.

Applications

The AlN Ceramic Heater Plate is used in several high-tech industries where efficient heat management and high thermal stability are essential:

- Semiconductor Industry: Used for wafer trays, chip packaging, and other high-precision electronic products for heat dissipation and isolation.

- High-Power Electronic Devices: Ideal for applications such as solid-state transistors, LED heat sinks, and other devices that require heat management to enhance performance.

- High-Power Heating Systems: Suitable for use in heating systems, lasers, and laser cutting equipment where efficient thermal management is critical.

- Other High-Temperature Environments: Employed in environments with high temperatures, high pressures, or other specialized conditions requiring reliable heat dissipation.

new material

new material