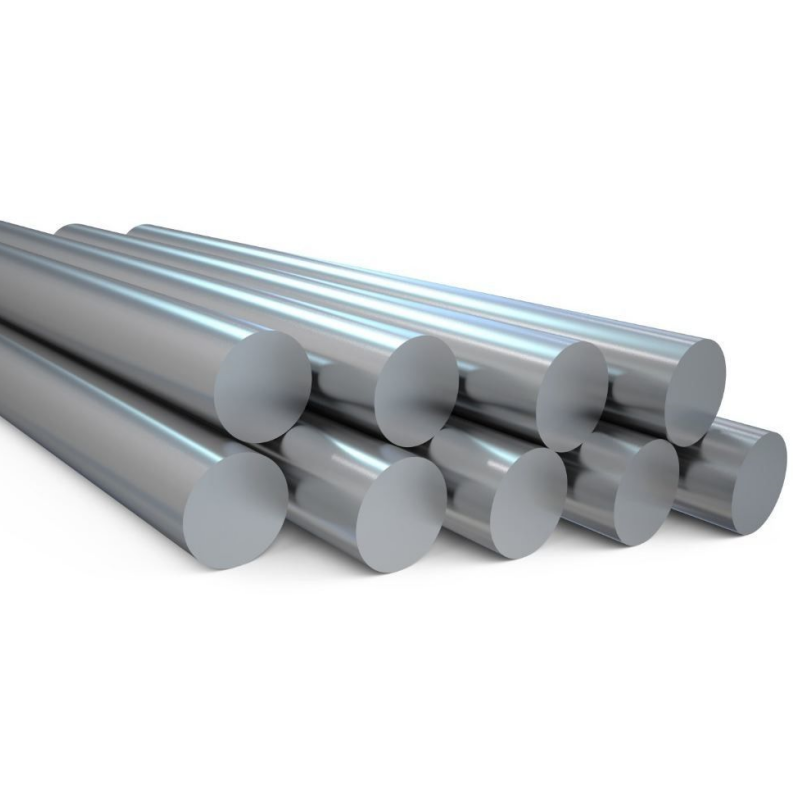

Product Overview:

Aluminium bars are silver-white, lightweight metallic products made from high-purity aluminium (99.99%–99.9999%). The manufacturing process involves casting, refining, impurity removal, degassing, and slag removal, resulting in products ideal for industrial applications requiring excellent corrosion resistance and strength. With customizable diameters and lengths, aluminium bars cater to a wide range of industry-specific needs.

Product Features:

- High Purity: Available in 99.99%, 99.999%, and 99.9999% purity grades to meet stringent industrial requirements.

- Superior Mechanical Properties: Offers excellent strength, corrosion resistance, and machinability.

- Customizable Sizes: Available in various shapes, including round, square, and hexagonal bars, and can be tailored to specific dimensions upon request.

- Versatile Applications: Suitable for diverse industries such as electronics, aerospace, and construction.

Applications:

- Building and Decoration: Aluminium bars are widely used for manufacturing doors, windows, curtain walls, railings, and other structural components, offering excellent corrosion resistance and durability.

- Electronics Industry: Used in producing components such as transmission pipes in air conditioning systems, high-voltage terminal shields, computer casings, and appliance parts.

- Sports Equipment: Aluminium bars are employed in fitness equipment, pulleys, and zip line hardware for their strength and lightweight characteristics.

- Aerospace: Due to their lightweight and excellent mechanical properties, aluminium bars are utilized in making aircraft components and satellite structures.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | Zn | <5 | ppm | Pb | <5 | ppm | |||||

| B | Ga | Bi | <5 | ppm | |||||||

| F | Ge | Y | |||||||||

| Na | As | <10 | ppm | Th | |||||||

| Mg | <10 | ppm | Se | Er | |||||||

| Al | Matrix | wt% | Zr | <5 | ppm | Ru | |||||

| Si | Nb | Rh | |||||||||

| P | Mo | Os | |||||||||

| Cl | Pd | Cd | <5 | ppm | |||||||

| K | Ag | In | |||||||||

| Ca | Sn | <10 | ppm | ||||||||

| Ti | <10 | ppm | Sb | <5 | ppm | ||||||

| V | <10 | ppm | Ba | ||||||||

| Cr | <5 | ppm | Hf | ||||||||

| Mn | <5 | ppm | Ta | C | |||||||

| Fe | 6 | ppm | W | S | |||||||

| Co | 12 | ppm | Pt | O | |||||||

| Ni | 10 | ppm | Au | N | |||||||

| Cu | 10 | ppm | Hg | H |

new material

new material