Active titanium dioxide sulfur recovery catalyst is a specialized catalytic material designed for efficient sulfur recovery in refining and industrial processes. Engineered with optimized titanium dioxide formulations, it enhances reaction kinetics, promotes high sulfur conversion efficiency, and ensures prolonged operational lifespan. This catalyst plays a critical role in Claus and tail gas treatment units, helping to maximize sulfur recovery, reduce emissions, and improve environmental sustainability.

Product Overview

The active titanium dioxide sulfur recovery catalyst is specifically designed for the Claus sulfur recovery process. It is primarily used to catalyze the reaction of hydrogen sulfide (H₂S) with sulfur dioxide (SO₂) to produce elemental sulfur. This catalyst boasts exceptional resistance to sulfidation, enabling effective sulfur recovery under high-temperature and high-pressure conditions. Compared to traditional alumina-based catalysts, the titanium dioxide-based catalyst effectively prevents the formation of sulfate salts, extends the catalyst's service life, and exhibits excellent reactivity and stability in high-oxygen environments.

Key Features

- Sulfation Resistance: Effectively reduces sulfate formation, preventing a decrease in surface area and extending the catalyst’s service life.

- High Organic Sulfur Conversion at Low Temperatures: Capable of efficiently converting organic sulfur even at lower temperatures, improving reaction efficiency.

- Strong Oxygen Removal Function: Effectively removes oxygen from the feed gas, protecting the sulfur recovery catalyst and maintaining high reactivity.

- Excellent Thermal Stability: Performs stably under high temperature and pressure, adapting well to the harsh conditions of the Claus process.

- Long Service Life: Offers a longer service life compared to traditional alumina-based catalysts, reducing replacement frequency and lowering operational costs.

Applications

- Sulfur Recovery Process: Widely used in Claus sulfur recovery units, facilitating the reaction of hydrogen sulfide and sulfur dioxide to produce elemental sulfur.

- Gas Purification and Desulfurization: Used in gas purification processes to efficiently remove organic sulfur, ensuring stable and efficient operation of sulfur recovery systems.

- Environmental Protection: Helps reduce organic sulfur emissions, meeting increasingly stringent environmental standards.

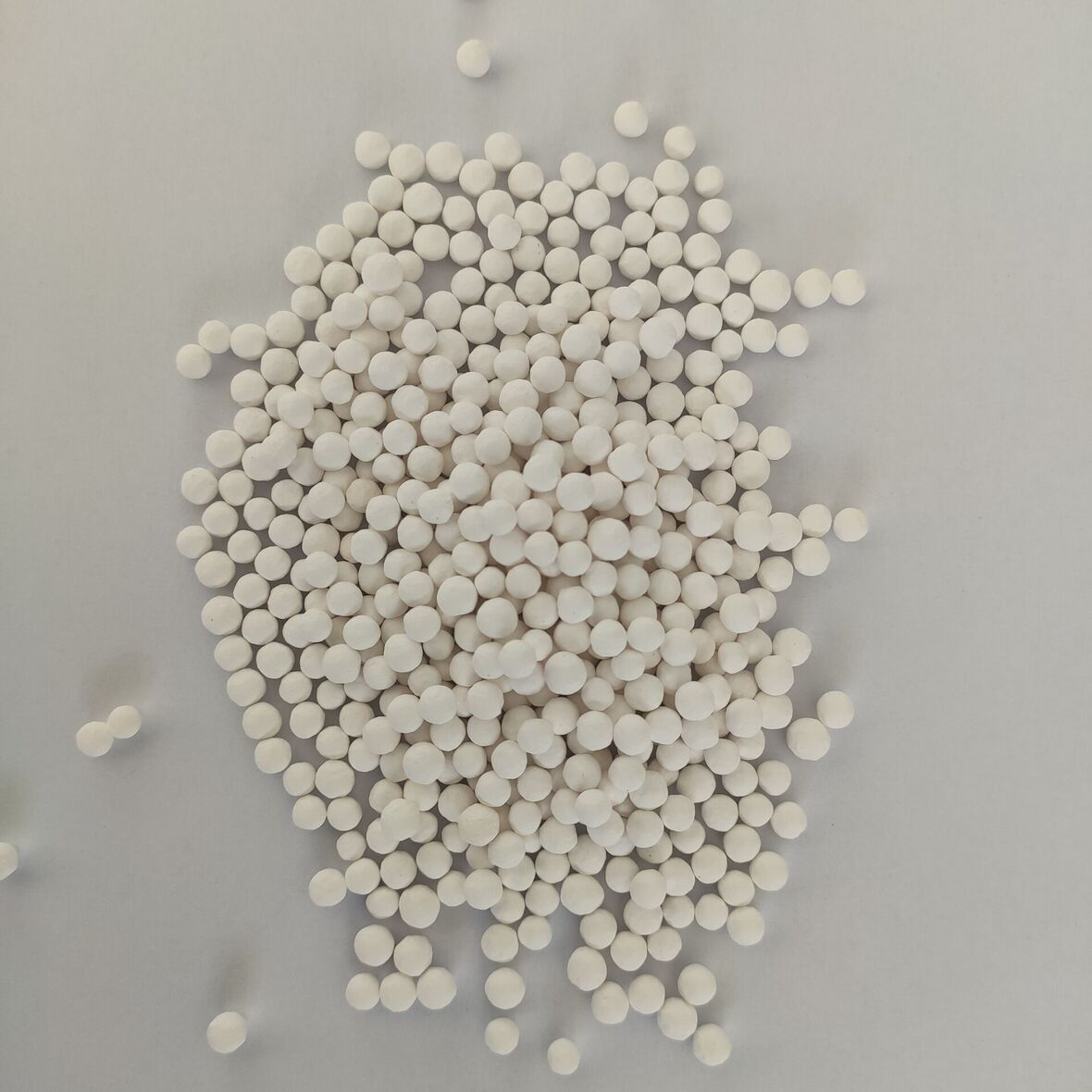

| Property Name | Value |

| Appearance | White spherical |

| Particle Size (mm) | Φ3~Φ8 |

| TiO2 % (wt) | ≥85 |

| Al2O3 % (wt) | ≥94 |

| Specific Surface Area (m²/g) | ≥300 |

| Pore Volume (ml/g) | ≥0.4 |

| Bulk Density (g/ml) | 0.72±0.05 |

| Strength (N/particle) | 100 |

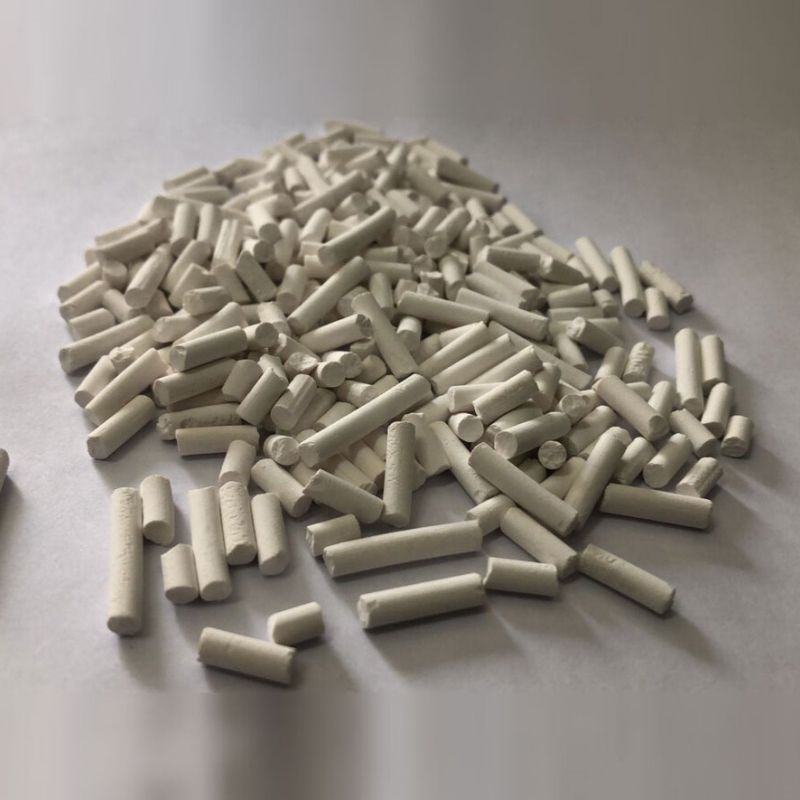

| Property Name | Value |

| Appearance | ф(3-4)×(5~15) White strip |

| Pressure Strength (N/cm) | ≥100 |

| Bulk Density (Kg/L) | 0.80~1.00 |

new material

new material