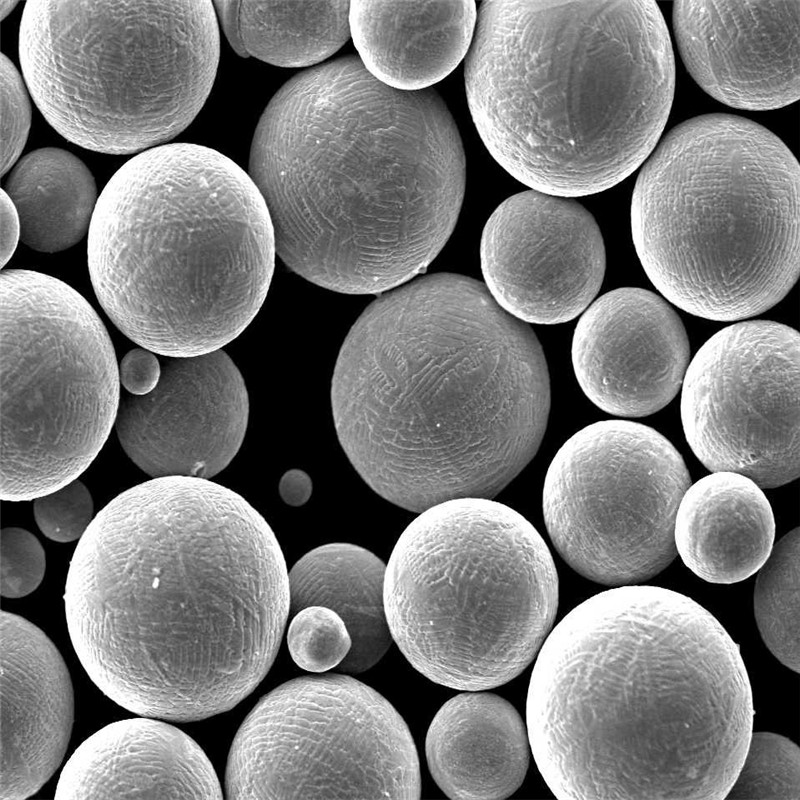

18Ni300 Mold Steel Powder is a maraging steel powder widely used in the tooling, aerospace, and engineering industries. This material is known for its exceptional hardness, high strength, and excellent toughness, as well as its ability to be heat-treated for improved performance. It is ideal for additive manufacturing and precision molding applications, producing durable and high-performance components with excellent wear resistance.

Product Overview

18Ni300 Mold Steel Powder is a high-strength and tough mold steel alloy powder, widely used in high-performance mold manufacturing. Through special heat treatment processes, this steel powder maintains excellent mechanical properties at high temperatures, making it suitable for applications requiring high wear resistance, toughness, and high-temperature resistance. Its exceptional performance makes it a critical material for the production of complex, precise molds.

Product Features

- High Strength and Toughness:Provides superior strength and toughness, capable of withstanding high loads and impact forces.

- High-Temperature Performance:Suitable for high-temperature environments, maintaining excellent stability and performance under extreme conditions.

- Excellent Wear Resistance:Effectively resists wear and extends the lifespan of molds.

- Superior Machinability:Easy to process, ideal for the manufacture of complex and precise molds.

- Corrosion Resistance:Offers good corrosion resistance, suitable for harsh working environments.

Applications

- Mold Manufacturing:Primarily used for producing high-performance molds, especially those requiring high strength and wear resistance.

- Automotive Industry:Used for producing automotive parts molds, stamping molds, etc.

- Aerospace:Applied in the production of aerospace components molds.

- Precision Machining:Utilized in the manufacture of high-precision molds and tools, widely used in various precision machining fields.

new material

new material