1,6-Hexanediol hydrogenation deoxygenation catalyst is a high-performance catalytic material designed to facilitate the selective hydrogenation and deoxygenation of hexanediol compounds with superior efficiency. Engineered using advanced metal-supported formulations, it ensures optimized reaction kinetics, enhanced yield, and prolonged operational stability for large-scale industrial applications. This catalyst is widely used in fine chemical manufacturing, polymer precursor synthesis, and industrial organic processing, providing reliable performance in controlled reaction environments.

Product Overview:

The 1,6-hexanediol hydrogenation deoxygenation (HDO) catalyst is specially designed for the hydrogenation deoxygenation process of 1,6-hexanediol, offering high catalytic performance. This catalyst is composed of copper oxide, zinc oxide, and bauxite as the primary chemical components. It exhibits excellent compressive strength and high bulk density, allowing it to maintain outstanding catalytic activity under stringent process conditions. It is suitable for medium- to low-pressure hydrogenation processes, significantly enhancing product purity and conversion rates.

Key Features:

- High Catalytic Activity:The synergistic effect of copper and zinc enhances catalytic performance, making it adaptable to various reaction environments.

- Strong Compressive Strength:The catalyst has a high radial compressive strength, ensuring stability under harsh reaction conditions.

- Good Stability:Optimized chemical composition improves the catalyst's stability and extends its service life.

- High Bulk Density:This feature enhances catalyst packing efficiency in reactors, reducing usage and equipment costs.

Applications:

- 1,6-Hexanediol Hydrogenation Deoxygenation:Widely used in the industrial production of 1,6-hexanediol to achieve higher product purity.

- Petrochemical Industry:Commonly applied in petrochemical processes, particularly those requiring efficient hydrogenation deoxygenation.

- Fine Chemicals:Used in the synthesis and refining of other fine chemicals to enhance reaction efficiency and product quality.

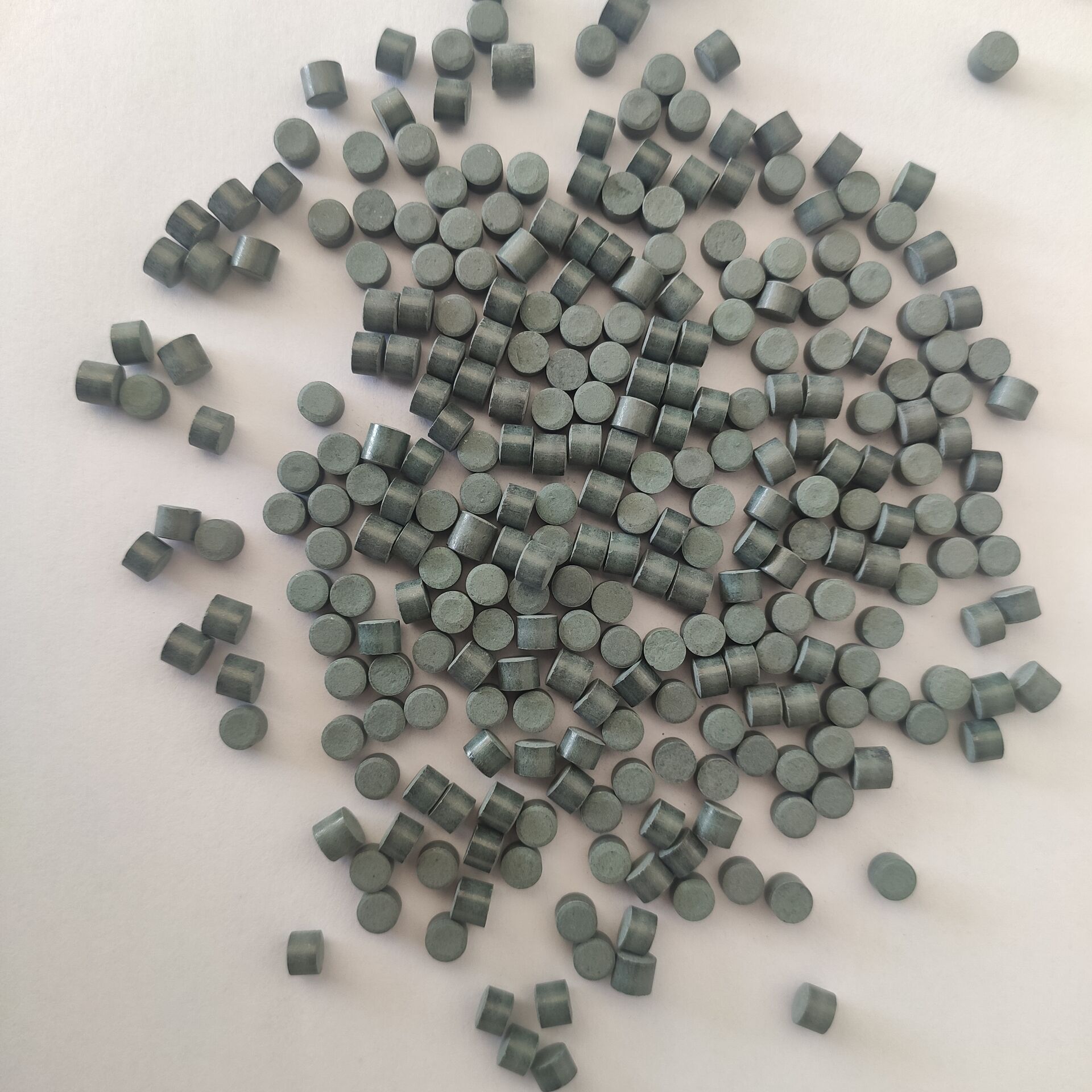

| Item | Specification |

| Appearance | Flake |

| Size | ∮5×5 mm |

| Radial Crushing Strength | ≥250 N/cm |

| Bulk Density | 1.45±0.05 kg/L |

| Chemical Composition | CuO-ZnO-Al₂O₃ ≥ 100% |

new material

new material