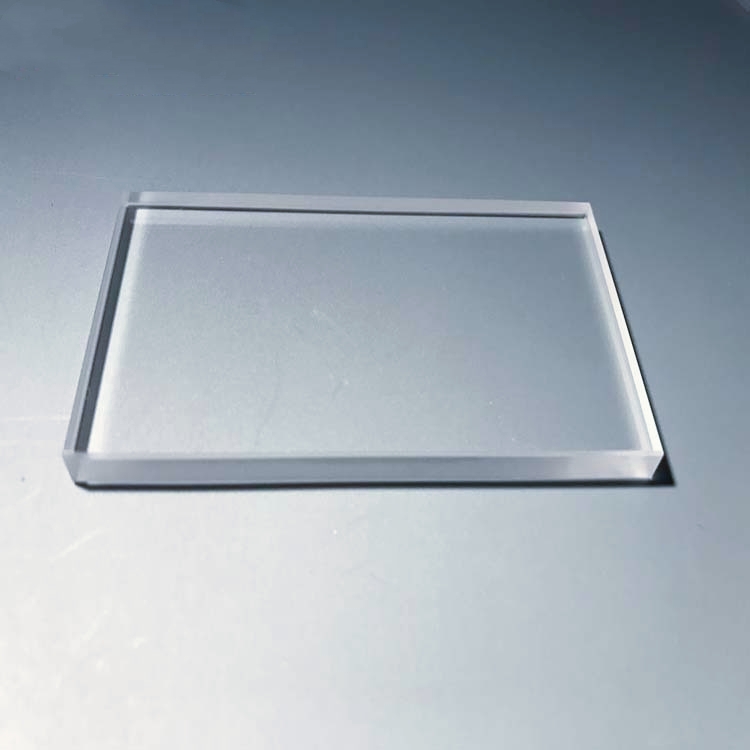

Sapphire rectangular window is a high-performance optical component known for its exceptional hardness, superior thermal stability, and broad spectral transmission. Manufactured from crystalline sapphire (Al₂O₃), it provides outstanding optical clarity, excellent resistance to scratches and chemical degradation, and high durability, making it ideal for aerospace applications, laser systems, high-temperature environments, and precision optical instruments. Its ability to withstand extreme conditions ensures long-term reliability in industrial and scientific applications.

Product Overview

The sapphire rectangular window is a high-performance optical element made from sapphire crystals, widely used for protecting sensors, detectors, and other high-precision optical systems. Its exceptional mechanical and optical properties make it an ideal choice for high-demand environments. Sapphire windows are typically manufactured using techniques such as glue disc polishing, high-speed polishing, ring polishing, and CNC polishing to ensure high precision, flatness, and light transmittance.

Key Features

- Excellent Transparency: Sapphire windows have outstanding optical transmission, effectively transmitting light and reducing reflection losses, thereby enhancing the performance of optical systems.

- High Hardness and Wear Resistance: Sapphire is extremely hard and can resist scratches and wear, providing long-term stability in harsh environments.

- Chemical Stability: Sapphire materials have excellent corrosion resistance and can work stably in various chemical environments.

- High-Temperature Resistance: Sapphire offers excellent thermal stability and can operate reliably in high-temperature environments for extended periods.

- High Precision Processing: Advanced processing techniques ensure high-precision, flat surfaces, meeting the stringent requirements of optical systems.

- Aspheric Design: Can be designed as an aspheric element to reduce astigmatism, chromatic aberration, and distortion, improving image quality.

Applications

- Infrared Imaging Systems: Used in infrared optical systems to enhance image sharpness and contrast.

- Spectrometers: Acts as a window material in optical systems to improve the accuracy and reliability of spectral analysis.

- Sensor Protection Windows: Protects sensors or detectors from environmental influences, ensuring system stability.

- High-Precision Optical Systems: Suitable for optical systems that require high-quality imaging and superior optical performance.

- High-Temperature Applications: Used in aerospace, military, and industrial fields that demand performance in high-temperature environments.

| Optical Property | Value |

| Transmission Range | 0.2-5 μm |

| Refractive Index (Ne) | 1.7771 |

| Structure | Trigonal crystal system |

| Physical Property | Value |

| Density | 3.98 g/cm³ |

| Melting Point | 2030 ℃ |

| Thermal Conductivity | 25.2 W/(m·℃) |

| Thermal Expansion | 5.66×10⁻⁶ ℃⁻¹ |

| Specific Heat Capacity | 0.7610×10³ J/(kg·℃) |

| Young's Modulus | 34-37 GPa |

| Volume Elasticity Coefficient | 250 GPa |

| Poisson's Coefficient | 0.309 |

| Chemical Property | Value |

| Molecular Weight | 101.96 g/mol |

| Solubility | 98×10⁻⁶ g/L |

| Parameter | Range |

| Diameter Range | 2-300 mm |

| Thickness | 0.12-60 mm |

| Surface Finish | 80-50, 60-40, 40-20, 20-10, 10-5 |

| Surface Accuracy | λ/2, λ/4, λ/8, λ/10 |

| Parallelism | <3' - 30" |

| Aperture Transmission | >90% |

| Coating | Customizable |

new material

new material