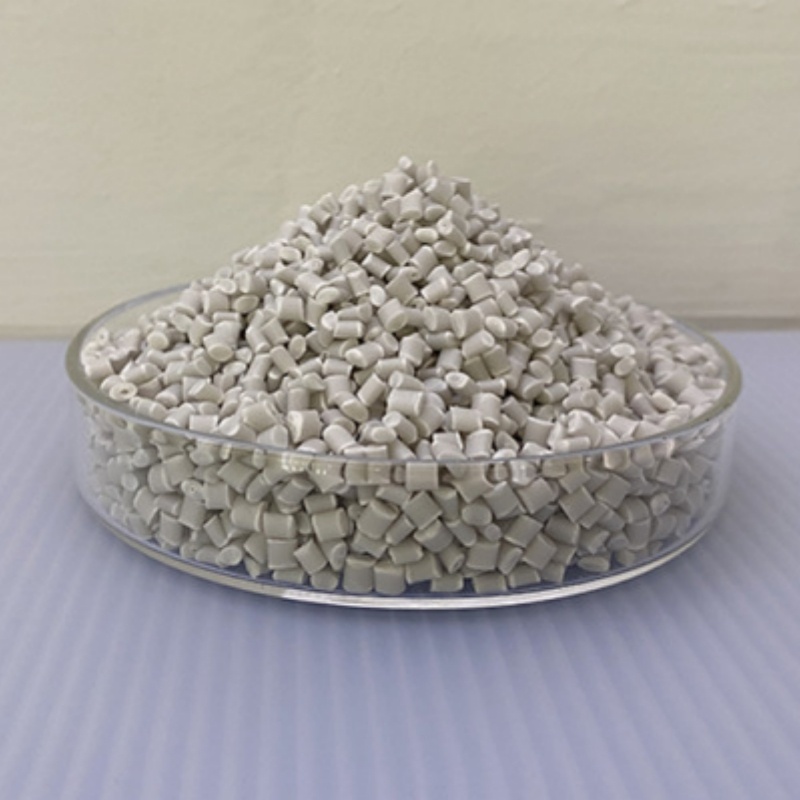

PP Translucent Grey Masterbatch offers high-quality pigmentation, excellent dispersion, and superior thermal stability. Designed for automotive, electrical, and industrial applications, it ensures consistent grey coloration, durability, and optimized polymer processing.

Product Description:

PP Translucent Grey Masterbatch is a specially designed color masterbatch for modifying polypropylene materials. It uses high-purity polypropylene as the carrier and offers excellent dispersion and UV resistance properties. This product provides a translucent grey effect, making it ideal for applications that require specific visual appeal and light transmittance. It is widely used in various plastic processing methods, especially for applications that require special aesthetic properties. Suitable for extrusion, injection molding, and blown film processes, it meets the diverse needs of different industries.

Product Features:

- Excellent Dispersion:The color masterbatch disperses uniformly, ensuring consistent color and high-quality finished products.

- UV Resistance & Color Retention:Features outstanding weather resistance, maintaining stable color and preventing fading, making it ideal for applications exposed to sunlight.

- Translucent Grey Effect:Provides a unique translucent grey appearance, perfect for applications that require distinctive visual properties.

- Good Processing Performance:Suitable for a variety of processing methods, including blown film, extrusion, and injection molding, ensuring excellent processing stability and high-quality results.

Applications:

- Packaging Materials:Can be used to produce translucent grey packaging films and materials, widely applicable in industries such as food packaging, electronics, and more.

- Plastic Products:Ideal for producing various plastic products requiring a unique appearance, especially those with special aesthetic needs.

- Customization Services:Offers customized masterbatch formulations based on customer requirements, catering to different color and functional demands.

| Grade | Color | Applicable Materials | Application | Recommended Dosage |

| WB001 | Black | PC, ABS, PS, PP, PE | Injection | 1-4% |

| WB002 | Black | PP, PE | Injection, Extrusion | 1-4% |

| WB003 | Black | ABS, PS, PP, PE, PVC, EVA, POM | Injection | 1-4% |

| WB004 | Black | PP, PS | Injection, Extrusion | 1-4% |

| WB005 | White | ABS, PS, PP, PE, PVC, PET | Injection, Blow Molding | 1-4% |

| WB006 | White | PP, PE | Injection, Extrusion | 1-4% |

| WB007 | Pearl | ABS, PS, PP, PE, PVC, EVA, PET | Injection, Blow Molding | 1-4% |

| WB008 | Silver | ABS, PS, PP, PE, PVC, EVA, PET | Injection, Blow Molding | 1-4% |

| WB009 | Gold | ABS, PS, PP, PE, PVC, EVA, PET | Injection, Blow Molding | 1-4% |

| WB010 | Antistatic | PP, PE | Injection, Blow Molding, Extrusion | 1-4% |

| WB011 | Flame Retardant | PE, PP, PS, ABS | Injection, Blow Molding | 10-20% |

new material

new material