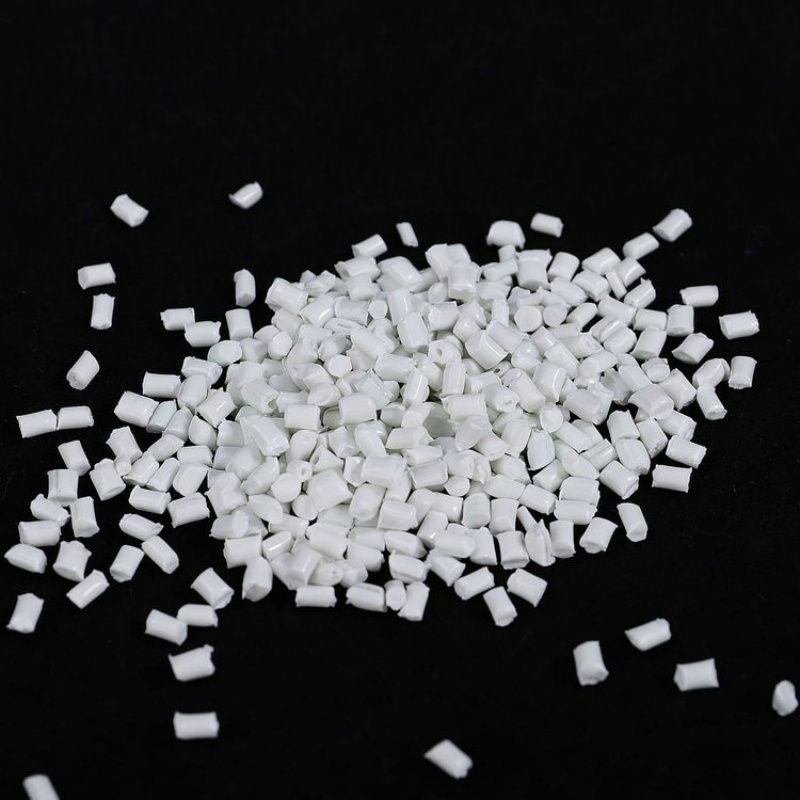

PA6 + 30% GF Weather-Resistant Nylon 6 provides optimized mechanical strength, superior durability, and enhanced resistance to environmental factors. Designed for automotive, industrial, and outdoor applications, it ensures long-term reliability, lightweight efficiency, and high adaptability.

Product Overview

PA6 + 30% GF Weather Resistance is a Nylon 6 material reinforced with 30% glass fiber and treated with a special weather-resistant formulation. This material exhibits excellent anti-aging and weathering properties when exposed to environmental conditions such as UV rays and moisture. It maintains outstanding performance in various outdoor applications, particularly suitable for automotive and outdoor equipment components.

Key Features

- Excellent Weather Resistance: Effectively resists aging and degradation under exposure to sunlight, moisture, and temperature fluctuations, maintaining stable physical properties.

- Outstanding Overall Performance: Offers good mechanical strength and impact resistance, making it suitable for demanding working environments.

- Superior Surface Appearance: The material has a smooth surface and is easy to process, making it ideal for applications requiring high aesthetic quality.

Applications

PA6 + 30% GF Weather Resistance is widely used in outdoor and automotive applications, including:

- Automotive Parts: Suitable for external automotive components such as door handles, side mirrors, and other weather-exposed parts.

- Outdoor Equipment: Ideal for components exposed to outdoor environments, such as vehicle light housings, dashboards, and more.

- Home Appliances & Other Industrial Fields: Also has broad applications in components requiring high weather resistance and exposure to the elements.

| Test Item | Unit | Test Method | Test Condition | Typical Values |

| Physical Property | ||||

| Density | g/cm³ | ISO 1183 | - | 1.36 |

| Filler Content | % | ISO 1172 | GF30 | - |

| Mold Shrinkage | % | ISO 294 | Parallel 0.2, Vertical 0.6 | - |

| Mechanical Property | ||||

| Tensile Strength | MPa | ISO 527 | I-type sample, 50mm/min | 180 |

| Elongation at Break | % | ISO 527 | I-type sample, 50mm/min, Gauge 50mm | 3 |

| Flexural Strength | MPa | ISO 178 | 23℃, 10mm/min | 240 |

| Flexural Modulus | MPa | ISO 178 | 23℃, 10mm/min | 8500 |

| Izod Impact Strength (Notched) | KJ/m² | ISO 180 | 23℃ | 16 |

| Charpy Impact Strength (Unnotched) | KJ/m² | ISO 179 | 23℃ | 95 |

| Thermal Property | ||||

| Melting Point | ℃ | ISO 11357-1 | - | 220 |

| Heat Deflection Temperature | ℃ | ISO 75 | 0.45MPA 219℃, 1.8MPA 205℃ | 219, 205 |

| Flammability | ||||

| Flammability Class | UL-94 | - | HB | |

| Glow Wire Ignition Temperature | ℃ | IEC 60695-2-13 | - | - |

| Electrical Property | ||||

| Surface Resistivity | Ω | IEC 60093 | - | 100000000000000 |

| Volume Resistivity | Ω•cm | IEC 60093 | - | 1000000000000000 |

new material

new material