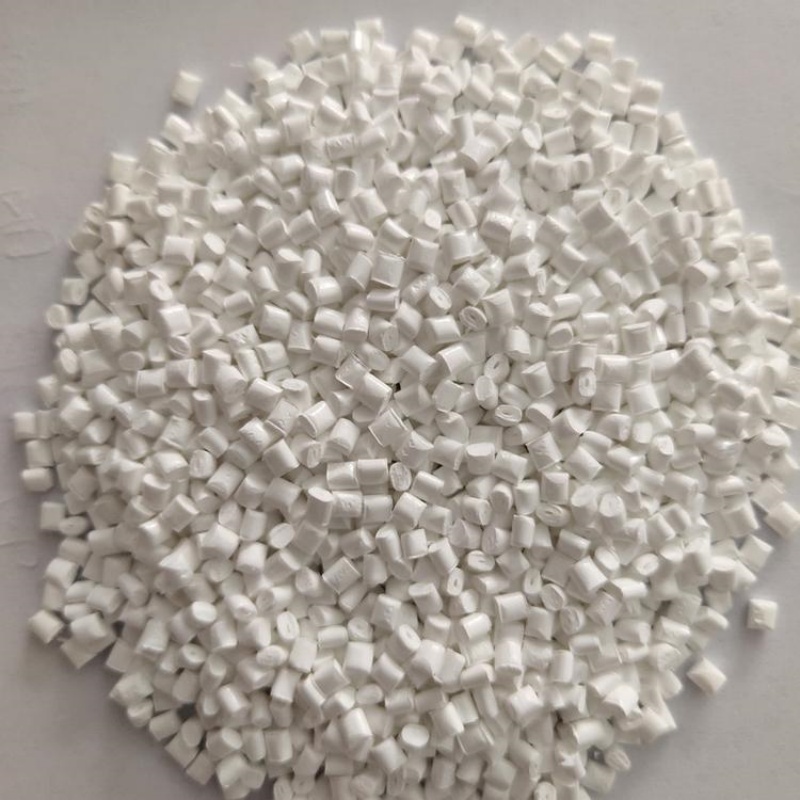

PA66+25GF (25% Glass Fiber Reinforced Polyamide 66) offers high mechanical strength, superior impact resistance, and enhanced thermal stability. Designed for automotive, industrial, and structural applications, it ensures durability, lightweight efficiency, and reliable long-term performance.

Product Overview

PA66+25GF is a high-performance composite material made by reinforcing polyamide 66 (Nylon 66) with 25% glass fiber. This material offers outstanding overall performance, combining excellent mechanical strength, electrical properties, and heat resistance. It is ideal for industrial applications that require high load-bearing capacity and performance in complex environments.

Key Features

- Outstanding Overall Performance: Glass fiber reinforcement enhances the material's mechanical strength, rigidity, and wear resistance.

- Excellent Electrical Properties: The material provides good electrical insulation, making it suitable for applications with high electrical performance requirements.

- High Thermal Stability: The material exhibits strong thermal stability, maintaining stable physical properties even in high-temperature environments.

- Good Processability: Despite the high glass fiber content, the material retains good flowability, facilitating the molding of complex components.

Applications

- Mechanical Components: Suitable for mechanical parts, offering high strength and wear resistance, especially in high-load components.

- Automotive Parts: Used in automotive exterior parts, engine components, and other applications, providing excellent strength, heat resistance, and stability.

- Protective Housings: Ideal for producing protective housings for various electronic and mechanical devices, providing excellent protection.

- Shielding Components: Used in electronic devices for electromagnetic shielding, ensuring excellent electrical isolation and interference resistance.

- Coil Frames: Applied in motors, transformers, and other equipment for coil frames, providing good mechanical support and stability.

- Bearings and Bearing Retainers: Used in the manufacturing of bearings and bearing retainers, ensuring long-term high-load and high-precision operation.

| Test Properties | Unit | Test Method | Test Condition | Typical Value |

| Physical Properties | ||||

| Density | g/cm³ | ISO 1183 | 1.32 | |

| Filler Content | % | ISO 1172 | GF25 | |

| Mold Shrinkage | % | ISO 294 | Parallel: 0.3%, Vertical: 0.7% | |

| Mechanical Properties | ||||

| Tensile Strength | MPa | ISO 527 | Type I sample, 50mm/min | 160 |

| Elongation at Break | % | ISO 527 | Type I sample, 50mm/min, Gauge length 50mm | 3 |

| Flexural Strength | MPa | ISO 178 | 23℃, 10mm/min | 210 |

| Flexural Modulus | MPa | ISO 178 | 23℃, 10mm/min | 7000 |

| Izod Impact Strength (Notched) | KJ/m² | ISO 180 | 23℃ | 9 |

| Charpy Impact Strength (Unnotched) | KJ/m² | ISO 179 | 23℃ | 65 |

| Thermal Properties | ||||

| Melting Point | ℃ | ISO 11357-1 | 260 | |

| Heat Deflection Temperature (HDT) | ℃ | ISO 75 | 0.45MPa: 250℃, 1.8MPa: 245℃ | |

| Flammability | ||||

| UL Flammability Class | UL-94 | HB | ||

| Glow Wire Ignition Temperature (GWIT) | ℃ | IEC 60695-2-13 | - | |

| Electrical Properties | ||||

| Surface Resistivity | Ω | IEC60093 | 10000000000000 | |

| Volume Resistivity | Ω·cm | IEC60093 | 1000000000000000 |

new material

new material