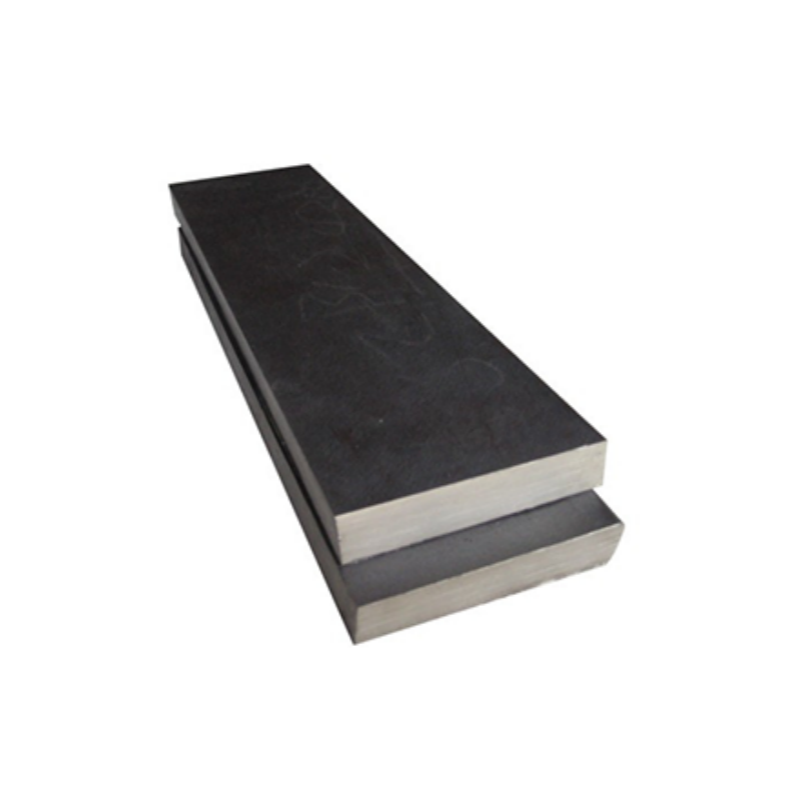

High-Temperature Alloy GH3030 is a nickel-based superalloy extensively used in aerospace, power generation, and high-temperature industrial applications. It is characterized by its excellent oxidation resistance, exceptional thermal stability, and superior mechanical strength, making it suitable for turbine components, furnace parts, and other critical components exposed to extreme thermal environments.

Product Overview

GH3030 is a solid-solution strengthened high-temperature alloy primarily used in industrial environments that require excellent high-temperature resistance, corrosion resistance, and good oxidation resistance. The alloy demonstrates good thermal strength and high plasticity below 800°C, making it ideal for high-temperature structural components and parts. After solid solution treatment, the alloy forms a single-phase austenitic structure, ensuring excellent durability, stability, and reliability in high-temperature applications.

Key Features

- Good Thermal Strength:GH3030 exhibits satisfactory thermal strength below 800°C, making it suitable for high-temperature load-bearing applications.

- High Plasticity:The alloy maintains good plasticity, allowing for various processing methods such as cold stamping, ensuring its adaptability for manufacturing complex parts.

- Excellent Oxidation Resistance:GH3030 demonstrates excellent oxidation resistance, ensuring stable performance in prolonged high-temperature environments.

- Good Thermal Fatigue Resistance:The alloy has strong resistance to thermal fatigue, making it suitable for high-temperature cyclic loading conditions.

- Superior Processability:With excellent cold stamping and welding capabilities, GH3030 is highly versatile and adaptable for various manufacturing and processing requirements.

- Structural Stability:The single-phase austenitic structure obtained through solid solution treatment ensures stable microstructure performance during long-term use at high temperatures.

Applications

- Aerospace Industry:GH3030 is widely used in aerospace applications, including turbine blades, engine combustion chambers, and other high-temperature components that must endure extreme conditions.

- High-Temperature Containers:The alloy is suitable for manufacturing containers and structural components that need to operate in high-temperature environments, such as pressure vessels and reactors.

- High-Temperature Protective Materials:GH3030 is used in protective applications, such as thermocouple protection tubes, where high temperature and oxidation resistance are critical.

- Heat Treatment and Welding Applications:Due to its excellent welding and cold stamping capabilities, GH3030 is ideal for manufacturing industrial equipment that requires high-temperature resistance, thermal fatigue endurance, and ease of fabrication.

| Alloy | % | Fe | Cr | P | Cu | Ni | Al | Ti | C | Mn | Si | V | S |

| GH3030 | 小 | 19 | Remaining | 0.15 | 0.1 | ||||||||

| 大 | 1 | 22 | 0.015 | 0.2 | 0.15 | 0.35 | 0.12 | 0.7 | 0.8 | 0.5 | 0.02 |

| Form | 20℃ Strength (σb /MPa) | 20℃ Elongation (δ5 /%) | 700℃ Strength (σb /MPa) | 700℃ Elongation (δ5 /%) |

| Cold Drawn Bar | 685 | 30 | 295 | |

| Hot Bar | 685 | 30 | 295 | 30 |

| Cold Rolled Bar | 685 | 30 | 30 | |

| Ring Forging | 685 | 30 | 30 |

new material

new material