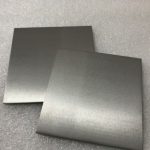

Product Overview

High purity niobium plates are materials known for their excellent physical and chemical properties, making them ideal for use in high-demand industrial and technological fields. These plates exhibit strong resistance to high temperatures and corrosive environments, making them especially suitable for high-temperature alloys and superconducting applications that require durable and high-strength materials.

Features

- High Purity:Ensures material stability and superior performance.

- Excellent Corrosion Resistance:Particularly stable in harsh chemical environments.

- High Temperature Stability:Can withstand temperatures as high as 2468°C.

- Good Ductility and Machinability:Easy to process into custom shapes.

- Strong Electrical and Thermal Conductivity:Reliable for applications requiring efficient heat and electrical flow.

Applications

- Nuclear Industry:Niobium plates are used in nuclear reactors and other nuclear equipment due to their low thermal neutron absorption.

- Superconducting Technology:Used in superconducting magnets and high-energy physics fields.

- High-Temperature Alloys:Niobium serves as a strengthening element in high-temperature alloys.

- Chemical Industry:Applied in chemical reaction vessels and equipment, offering exceptional corrosion resistance.

- Aerospace:Used in aerospace as a high-temperature structural material to endure extreme conditions.

- Arc Welding:Niobium is used in arc welding rods for welding stainless steel and alloys.

- Medical Applications:Due to its biocompatibility, niobium is used in medical devices.

- High-Pressure Sodium Lamps:Niobium-doped zirconium is used in high-pressure sodium lamp arc tube sealing materials.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | Zn | Pb | |||||||||

| B | Ga | Bi | |||||||||

| F | Ge | Y | |||||||||

| Na | As | Th | |||||||||

| Mg | Se | Er | |||||||||

| Al | Zr | <10 | ppm | Ru | |||||||

| Si | <5 | ppm | Nb | Matrix | wt% | Rh | |||||

| P | Mo | <10 | ppm | Os | |||||||

| Cl | Pd | Cd | |||||||||

| K | Ag | In | |||||||||

| Ca | Sn | ||||||||||

| Ti | <5 | ppm | Sb | ||||||||

| V | Ba | ||||||||||

| Cr | <10 | ppm | Hf | ||||||||

| Mn | Ta | 42 | ppm | C | 29 | ppm | |||||

| Fe | 10 | ppm | W | 20 | ppm | S | |||||

| Co | Pt | O | 100 | ppm | |||||||

| Ni | <10 | ppm | Au | N | 10 | ppm | |||||

| Cu | Hg | H | 10 | ppm |

new material

new material