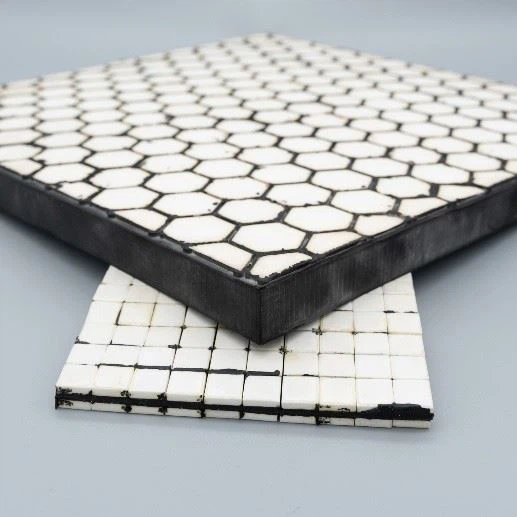

Microcrystalline wear-resistant alumina liners offer exceptional hardness, optimized abrasion resistance, and superior thermal stability. Designed for industrial applications, they ensure reliable protection, extended lifespan, and consistent operational efficiency.

Product Overview:

The Microcrystalline Wear-Resistant Alumina Liner is a high-performance ceramic material primarily composed of alumina and microcrystalline silicon. It boasts exceptional wear resistance, corrosion resistance, and high-temperature endurance. This product is widely used in industries that demand high-strength protection, especially in harsh working environments, effectively extending equipment service life and reducing maintenance costs.

Product Features:

- Superior Wear Resistance:The addition of microcrystalline silicon significantly improves the hardness and strength of alumina, providing excellent wear resistance for high-wear environments.

- Excellent Corrosion Resistance:Resists damage from acidic, alkaline, and saline environments, offering a long service life in corrosive conditions.

- Outstanding High-Temperature Performance:Withstands thermal shocks and cycles, maintaining stable performance in high-temperature industrial applications.

- High Dimensional Stability:The microcrystalline alumina liner exhibits minimal deformation and thermal expansion, ensuring precise dimensional requirements.

- Ease of Machining:Can be processed into complex shapes through cutting, drilling, grinding, and other techniques, meeting various application needs.

Applications:

- Coal Mining Industry:Used in high-wear environments, such as ore conveyor systems, to reduce equipment wear.

- Metallurgical Industry:Protects smelting and metal processing equipment from high temperatures and wear.

- Chemical Industry:Suitable for corrosion-resistant pipes, containers, and equipment, enhancing durability.

- Power Industry:Used in power equipment protection, capable of withstanding high temperatures and intense wear.

- Petroleum Industry:Provides wear protection in oil exploration and processing, extending equipment life.

- Light Industry:Applied to mechanical protection in light industrial production, reducing wear and maintenance costs.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform