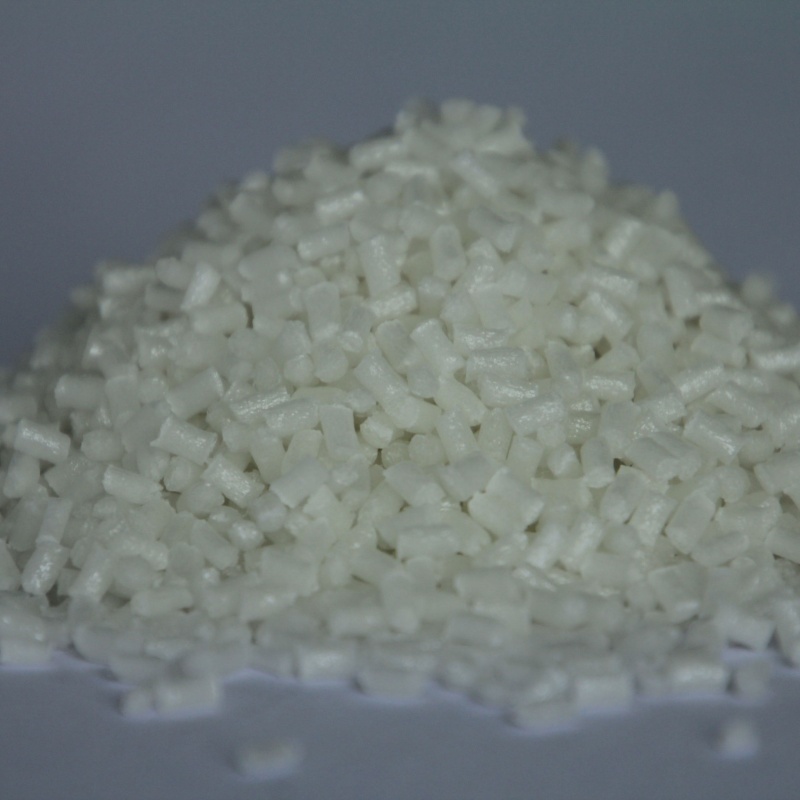

Glass Fiber Reinforced PC (Polycarbonate) provides enhanced mechanical strength, superior dimensional stability, and excellent thermal resistance. Designed for automotive, electrical, and industrial applications, it ensures durability, impact resistance, and long-term performance.

Product Overview

Glass Fiber Reinforced PC (Polycarbonate) is a composite material obtained by adding glass fibers to a polycarbonate matrix and treating it through a special process. The mechanical properties, heat resistance, and dimensional stability of this material are significantly improved. Glass fiber reinforced PC offers excellent fatigue strength, tensile strength, bending strength, and elastic modulus, enhancing its heat resistance and exhibiting low molding shrinkage. The material also possesses excellent toughness, strength, stress crack resistance, gloss, as well as plating and spraying performance. It can be customized based on specific customer requirements, including flame retardant, halogen-free flame retardant, and other modified options.

Key Features

- Superior Mechanical Properties: The incorporation of glass fibers significantly improves the material's fatigue strength, tensile strength, bending strength, and elastic modulus.

- Enhanced Heat Resistance: The material's heat resistance is greatly improved, making it suitable for high-temperature working environments.

- Excellent Dimensional Stability: With a low molding shrinkage rate, the material exhibits enhanced dimensional stability.

- Outstanding Toughness and Strength: While maintaining high strength, the material also improves toughness and stress crack resistance.

- Customizable Properties: Can be modified to include flame retardant, halogen-free flame retardant, and other performance enhancements to meet higher demands.

- Good Surface Performance: Suitable for electroplating and spraying, enhancing the appearance and decorative properties.

Applications

- Mechanical Industry: Widely used for manufacturing mechanical parts such as bearing cages, rails, gears, etc.

- Instruments and Electronics: Suitable for high-precision instrument components, electronic computer parts, distribution boards, electric tool housings, etc.

- Transportation: Extensively used in automotive components, aircraft parts, bicycle parts, etc., to enhance product strength and durability.

- Aerospace: Used to produce high-strength, lightweight aerospace parts, such as astronaut helmets.

- Other Industries: Suitable for various high-performance mechanical, instrument, and electrical products, providing reliable performance and stability.

| Product Model | Product Features | Main Applications |

| PC+10%GF | General-purpose | Speaker brackets, automotive, home appliances |

| FRPC+10%GF | V-0 grade halogen-free flame retardant | Frame for glue parts |

| PC+20%GF | General-purpose | Speaker brackets, automotive, home appliances |

| PC+30%GF | High rigidity | Speaker brackets, automotive, home appliances |

| FRPC | V-0 grade halogen-free flame retardant | Electronic and electrical components |

| Property | Test Method (ISO) | Unit | PCG10 | PCG20 | PCG30 |

| Melt Flow Rate | 1133 | g/10min | 9 | 7 | 6 |

| Density | 1183 | g/cm³ | 1.25 | 1.36 | 1.4 |

| Tensile Strength | 527 | MPa | 60 | 60 | 60 |

| Elongation | 527 | % | 5 | 5 | 1 |

| Flexural Strength | 178 | MPa | 92 | 93 | 97 |

| Flexural Modulus | 178 | MPa | 4000 | 5500 | 7200 |

| Notched Charpy Impact Strength | 179 | KJ/m² | 9 | 7 | 11 |

| Unnotched Charpy Impact Strength | 180/1A | KJ/m² | 10 | 8 | 12 |

| Heat Deflection Temperature | 75/A | ℃ | 130 | 135 | 138 |

| Flame Retardancy | UL-94 | 1.5mmHB | 1.5mmHB | 1.5mmHB | 1.5mmHB |

| Melt Flow Rate | 294 | % | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 |

new material

new material